Tel:

+8618931101301

Tel:

+8618931101301

nov . 21, 2024 02:37 Back to list

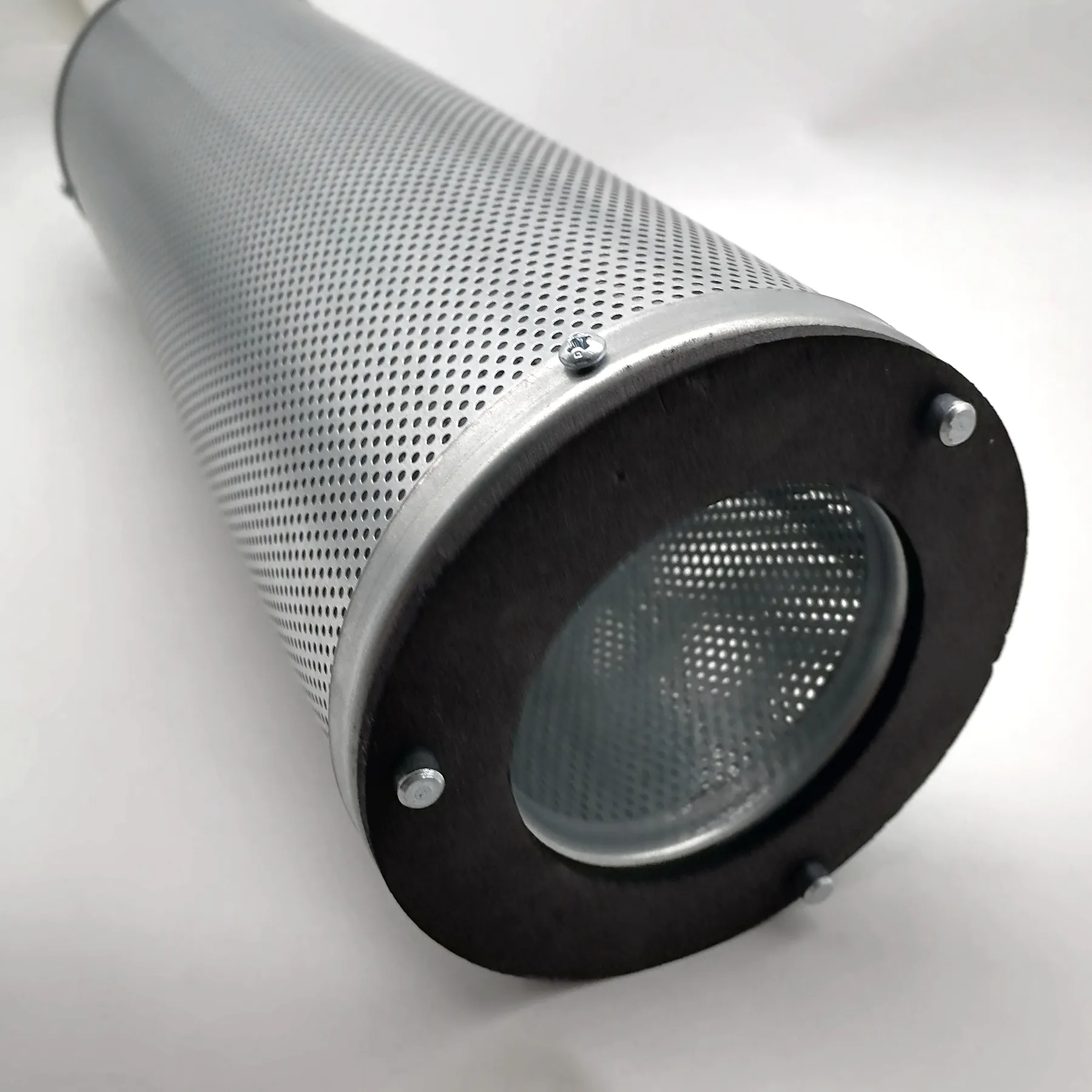

industrial air filter cartridges

Industrial Air Filter Cartridges Essential Components for Clean Air Solutions

In today's industrial landscape, maintaining clean air quality is not just a matter of comfort; it's a critical requirement for health, safety, and compliance. Industrial air filter cartridges play a pivotal role in achieving these standards by ensuring that airborne particles, contaminants, and pollutants are effectively removed from the air before it circulates in working environments. This article explores the significance of air filter cartridges, their types, applications, and best practices for maintaining optimal air quality in industrial settings.

Importance of Industrial Air Filter Cartridges

Air filter cartridges are integral to various industrial processes, such as manufacturing, pharmaceuticals, food processing, and power generation. These components trap harmful particulates, including dust, smoke, pollen, and chemical vapors, which can adversely affect both employee health and equipment performance. With increasing regulations on air quality, businesses are more than ever required to implement efficient air filtration systems to prevent respiratory issues among workers and to comply with environmental laws.

Types of Air Filter Cartridges

There are several types of industrial air filter cartridges available, each designed to handle specific contaminants and operating conditions. Here are some of the most commonly used types

1. HEPA Filters (High-Efficiency Particulate Air Filters) These filters are designed to capture 99.97% of particles that are 0.3 microns in size. HEPA filters are ideal for environments that require stringent air quality standards, such as clean rooms and hospitals.

2. Activated Carbon Filters These cartridges use activated carbon to adsorb odors, vapors, and volatile organic compounds (VOCs). They are particularly useful in applications where chemical fumes are present.

3. Pre-Filters Often employed in conjunction with other filters, pre-filters capture larger particles, thereby extending the life of subsequent filter elements. They help in reducing the load on HEPA or activated carbon filters.

4. Pocket Filters These filters feature a series of pockets that increase the filter surface area, allowing for higher dust-holding capacity and longer service life. They are typically used in HVAC systems in industrial buildings.

5. Oil Mist Filters Specifically designed for machining and metalworking environments, these cartridges capture oil mists and coolants released during manufacturing processes, thus protecting both workers and machinery.

Applications of Air Filter Cartridges

industrial air filter cartridges

Industrial air filter cartridges find applications in a wide array of industries

- Manufacturing Essential in controlling particulate emissions from processes like welding, sanding, and chemical processing. - Food and Beverage Maintains air quality to prevent contamination and ensure product safety. - Pharmaceuticals Critical for maintaining sterile environments and preventing cross-contamination in drug production. - Power Generation Used in gas and coal power plants to filter emissions and improve air quality in surrounding communities.

Best Practices for Maintenance and Replacement

To ensure that industrial air filter cartridges operate efficiently, regular maintenance and timely replacement are vital. Here are some best practices

1. Regular Inspections Conduct routine checks on filter conditions. Signs of excess dirt or damage indicate the need for replacement.

2. Use Monitoring Systems Implement pressure drop monitoring systems that alert when filters are becoming ineffective, ensuring timely changes.

3. Follow Manufacturer Guidelines Adhere to the recommended replacement schedules specific to your industrial environment and the type of filter being used.

4. Training Personnel Ensure that workers understand the importance of air filtration and are trained on how to replace filters safely and efficiently.

5. Keep Detailed Records Maintain records of filter replacements and inspections to track performance over time and ensure compliance with regulations.

Conclusion

Industrial air filter cartridges are vital for maintaining safe, clean air in various industrial environments. By understanding their types, applications, and proper maintenance, industries can significantly enhance air quality, protect workforce health, and comply with environmental standards. As innovations in filtration technology continue to evolve, businesses must stay informed about advancements to optimize their air quality management strategies and ensure a healthier workplace for all employees. Investing in high-quality industrial air filter cartridges is not just a regulatory compliance measure; it’s an investment in workforce productivity and well-being.

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

Email:

Email: