Tel:

+8615930870079

Tel:

+8615930870079

nov . 22, 2024 07:59 Back to list

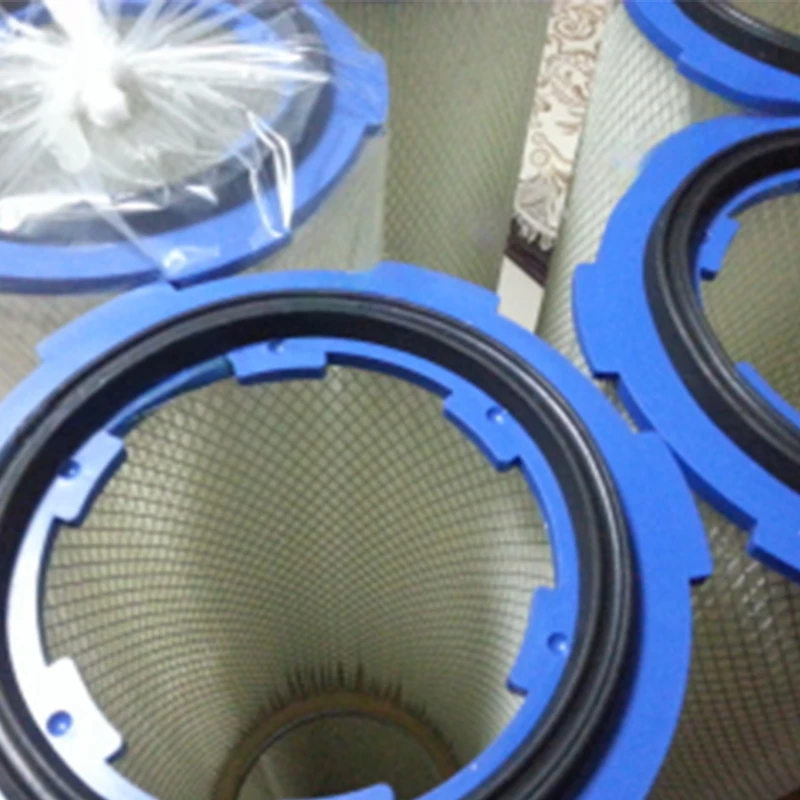

gas turbine inlet filter

Gas Turbine Inlet Filters Ensuring Efficiency and Longevity

Gas turbines play a crucial role in power generation and various industrial applications. However, their performance and longevity can be significantly impacted by the quality of air they ingest. This is where gas turbine inlet filters come into play. These filters serve as a front line of defense against contaminants such as dust, sand, and other particulate matter that can impair turbine function.

The primary purpose of gas turbine inlet filters is to provide clean air to the combustion process. Impurities in the air can lead to erosion and fouling of turbine components, ultimately affecting efficiency and increasing maintenance costs. Contaminated air can cause various issues such as reduced performance, increased emissions, and shorter operational lifetimes. By effectively filtering out these harmful particulates, inlet filters help maintain the turbine's operational integrity.

There are several types of filters commonly used in gas turbine applications. The most prevalent are synthetic media filters, which offer high dirt-holding capacity and efficient particle capture. These filters are designed to withstand harsh operating conditions, including high temperatures and varying humidity levels, making them ideal for gas turbine environments.

gas turbine inlet filter

Another important aspect of gas turbine inlet filters is their impact on performance. A well-designed filter can significantly reduce the pressure drop across the filter medium, enabling the turbine to operate more efficiently. A lower pressure drop allows for better airflow, resulting in improved combustion characteristics and increased overall efficiency. In contrast, a clogged or inefficient filter can restrict airflow, leading to decreased performance and increased fuel consumption.

Regular maintenance and monitoring of inlet filters are essential to ensure optimal performance. It is crucial that operators implement a scheduled replacement plan to avoid the risks associated with filter saturation. Many modern gas turbine systems are equipped with pressure differential sensors that alert operators when filters need maintenance, allowing for proactive measures to be taken before performance is compromised.

Moreover, advancements in filter technology have led to the development of smarter filtration systems. These systems often include features such as self-cleaning mechanisms and advanced monitoring capabilities, further enhancing their effectiveness and reducing the need for frequent manual maintenance.

In conclusion, gas turbine inlet filters are vital components that contribute to the overall efficiency and reliability of gas turbines. By ensuring that clean air enters the combustion process, these filters protect turbine components from damage, reduce operational costs, and enhance performance. As gas turbine technology continues to evolve, so too will the filtration solutions designed to meet the ever-increasing demands of efficiency and sustainability in power generation.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: