ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

feb . 17, 2025 18:59 Back to list

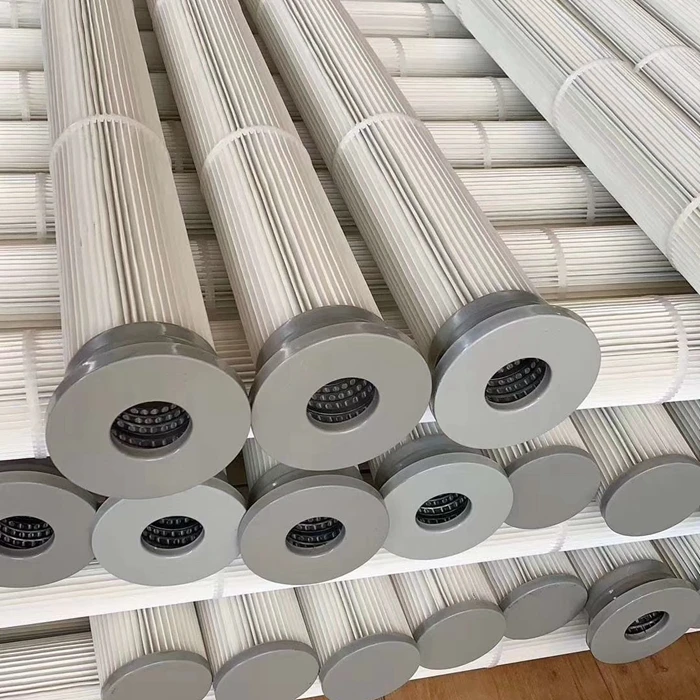

cartridge filter for dust collector

A filter cartridge dust collector represents a pivotal investment for industries where air quality maintenance is crucial. This advanced device is not only essential for worker health and safety but also vital for maintaining equipment efficiency and advocating environmental responsibility. With air pollution being a significant concern, understanding the intricacies of these systems can differentiate industry leaders from laggards in dust and fume management.

From an authoritative perspective, understanding regulatory standards like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) guidelines is essential for anyone involved in industrial air quality management. These standards mandate specific airborne contaminant concentration limits, and failure to comply can lead to severe penalties. Hence, a well-chosen filter cartridge dust collector not only mitigates human health risks but also safeguards the company against legal ramifications. Trustworthiness of a filter cartridge dust collector supplier plays a significant role in the decision-making process. Partnering with established manufacturers ensures access to technically proficient customer support and reliable maintenance services. Furthermore, an evidence-based evaluation of their products' performance—via air quality testing results and real-world case studies—can provide additional assurance of their systems' capability and longevity. Real-world experience exemplifies the effectiveness of these dust collectors. A case study involving a metal processing facility demonstrated a marked reduction in ambient metal particulate levels post-installation, leading to improved worker health metrics and a significant decrease in equipment downtime due to cleaner working environments. Such case studies can convincingly highlight the tangible benefits of implementing these advanced systems. In conclusion, the choice and implementation of filter cartridge dust collectors extend beyond mere compliance—it underscores a commitment to operational excellence and corporate responsibility. By focusing on authentic experiences, leveraging technical expertise, aligning with authoritative regulations, and fostering trust through reliable partnerships, industries can significantly enhance their environmental impact and operational integrity, ensuring long-term success and sustainability.

From an authoritative perspective, understanding regulatory standards like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) guidelines is essential for anyone involved in industrial air quality management. These standards mandate specific airborne contaminant concentration limits, and failure to comply can lead to severe penalties. Hence, a well-chosen filter cartridge dust collector not only mitigates human health risks but also safeguards the company against legal ramifications. Trustworthiness of a filter cartridge dust collector supplier plays a significant role in the decision-making process. Partnering with established manufacturers ensures access to technically proficient customer support and reliable maintenance services. Furthermore, an evidence-based evaluation of their products' performance—via air quality testing results and real-world case studies—can provide additional assurance of their systems' capability and longevity. Real-world experience exemplifies the effectiveness of these dust collectors. A case study involving a metal processing facility demonstrated a marked reduction in ambient metal particulate levels post-installation, leading to improved worker health metrics and a significant decrease in equipment downtime due to cleaner working environments. Such case studies can convincingly highlight the tangible benefits of implementing these advanced systems. In conclusion, the choice and implementation of filter cartridge dust collectors extend beyond mere compliance—it underscores a commitment to operational excellence and corporate responsibility. By focusing on authentic experiences, leveraging technical expertise, aligning with authoritative regulations, and fostering trust through reliable partnerships, industries can significantly enhance their environmental impact and operational integrity, ensuring long-term success and sustainability.

Latest news

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: