Tel:

+8615930870079

Tel:

+8615930870079

dec . 19, 2024 22:56 Back to list

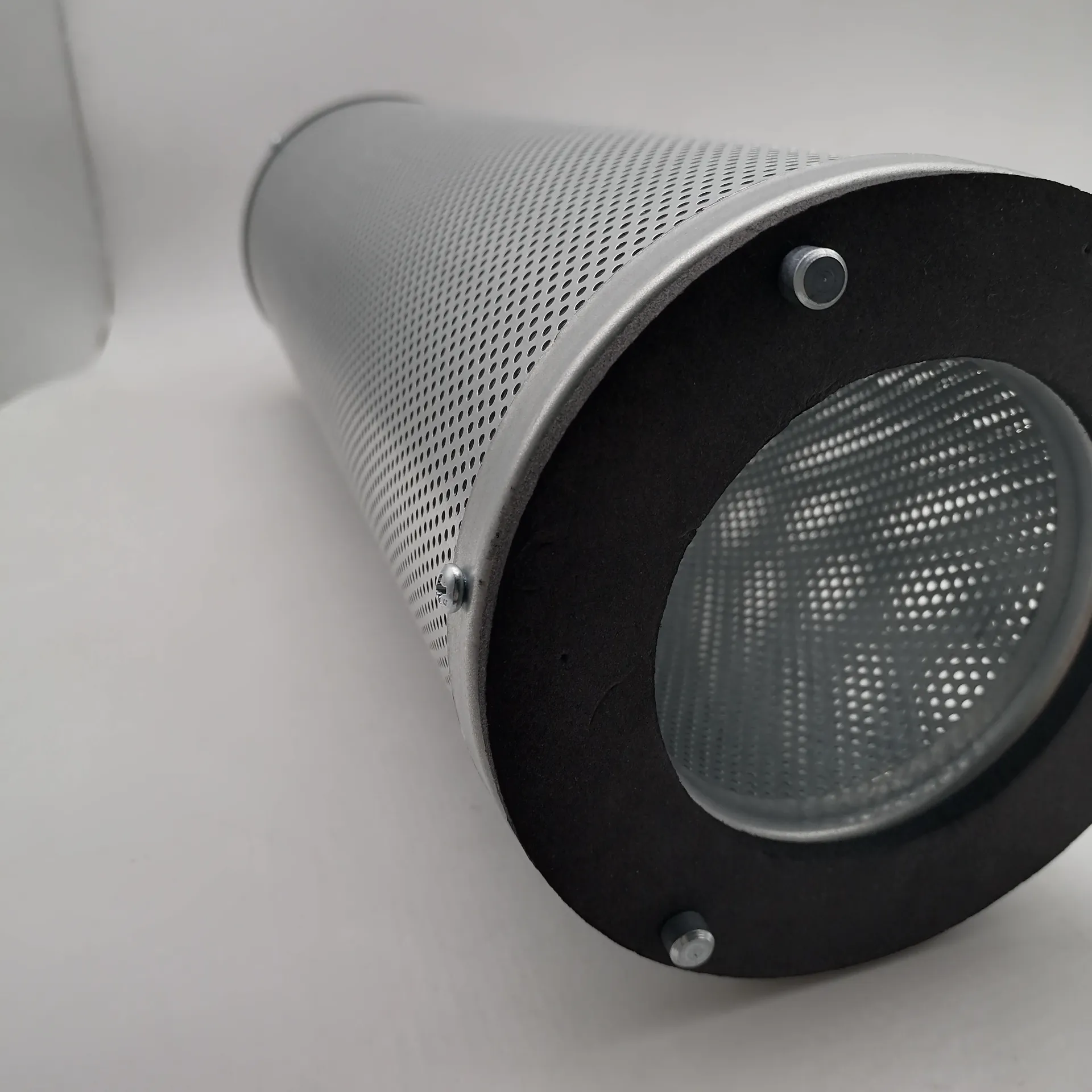

dust collector pleated filter

Understanding Dust Collector Pleated Filters

In industries where airborne dust and particles can negatively impact both the environment and human health, effective dust collection systems are essential. One of the most important components of these systems is the pleated filter, which plays a crucial role in ensuring clean air is released back into the environment. This article delves into the design, benefits, and applications of dust collector pleated filters.

What is a Pleated Filter?

A pleated filter is a type of air filter that consists of a series of folds (or pleats) arranged in a way that increases the surface area available for capturing dust and particles. Unlike traditional flat filters, pleated filters can trap more airborne contaminants due to their increased surface area. This design not only enhances filtration efficiency but also extends the lifespan of the filters, making them a preferred choice in many dust collection systems.

Benefits of Pleated Filters

1. Increased Filtration Efficiency

The pleated design allows for a larger effective filter area within a compact space. This means that pleated filters can capture finer particles, including dust, pollen, and other allergens. Depending on the materials used in their construction, some pleated filters can achieve efficiencies of up to 99.9% for particles as small as 0.3 microns.

Moreover, pleated filters have a longer service life compared to conventional flat filters. The increased dust holding capacity and lower face velocity help reduce the frequency of filter changes. This not only lowers maintenance costs but also minimizes downtime in operations, which is especially critical in industrial environments.

3. Cost-Effectiveness

dust collector pleated filter

While the initial investment for pleated filters may be higher than standard filters, their durability and efficiency often translate into long-term savings. By reducing replacement frequency and maintenance costs, these filters provide a more economical solution over time.

4. Versatile Applications

Pleated filters are incredibly versatile and can be utilized in various industries—from manufacturing and woodworking to pharmaceuticals and food processing. They are suitable for any application requiring efficient particulate capture, ensuring compliance with air quality regulations and improving workplace safety.

Selecting the Right Pleated Filter

When selecting a pleated filter for a dust collector system, several factors must be considered

- Particle Size and Type Different applications produce different types of dust and particles. Understanding the specific contaminants present in the environment will help in choosing the appropriate filter media. - Filter Material Pleated filters are made from various materials, including polyester, fiberglass, and cellulose. Each material has unique properties regarding dust retention and airflow, impacting the filter's performance.

- Filter Rating Filters come with different MERV (Minimum Efficiency Reporting Value) ratings, indicating their efficiency in capturing particles of varying sizes. Selecting the right MERV rating is essential for balancing air quality and airflow resistance.

- Airflow Requirements The design of the dust collection system must accommodate the properties of the pleated filter selected, ensuring adequate airflow and optimal performance.

Conclusion

Dust collector pleated filters play a pivotal role in maintaining air quality in various industrial settings. Their unique design offers increased filtration efficiency, longer service life, and cost-effectiveness, making them an essential investment for businesses focused on compliance and environmental responsibility. As industries continue to evolve and face new challenges, the role of advanced filtration technology, such as pleated filters, will remain crucial in ensuring a healthier workplace and a cleaner environment. By choosing the right pleated filter, businesses can optimize their dust collection systems and contribute to sustainability and safety.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: