Tel:

+8615930870079

Tel:

+8615930870079

nov . 30, 2024 08:10 Back to list

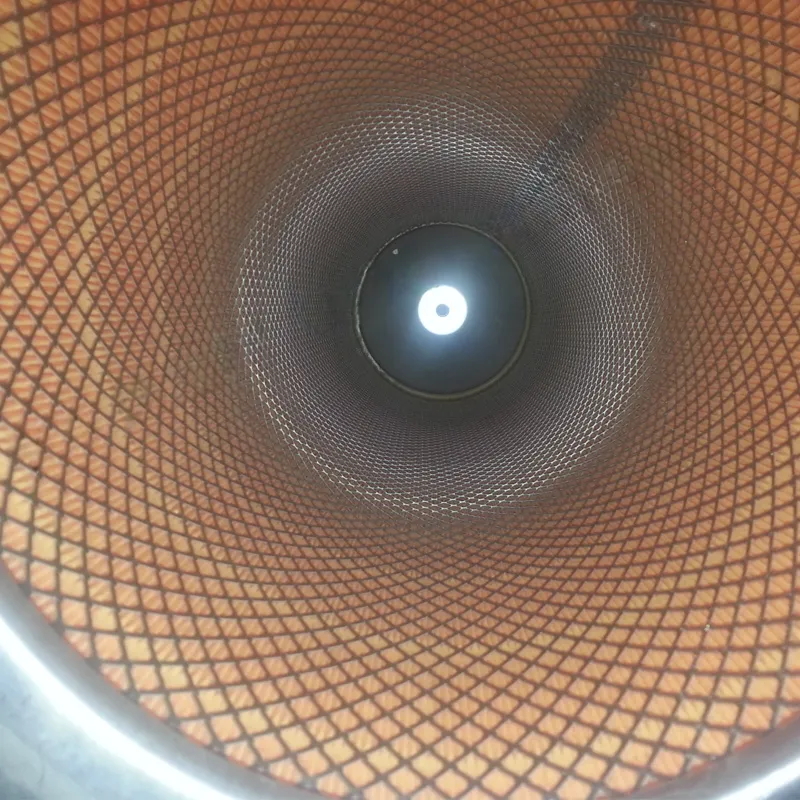

Dust Filter Cartridges for Enhanced Air Quality and Efficiency in Your Environment

Understanding Dust Cartridges Essential Components for Air Quality Control

In today’s industrial and commercial environments, maintaining air quality is a critical concern. Dust particles and other airborne contaminants can pose significant health risks to workers and consumers alike. One effective solution for maintaining clean air is the use of dust cartridges. These specialized filters play a pivotal role in a variety of applications, from manufacturing plants to HVAC systems, ensuring that the air we breathe is as clean as possible.

Dust cartridges are filtration devices designed to capture and remove dust, allergens, and other airborne particles from the air. They are typically made from various materials, including synthetic fibers, cellulose, and fiberglass, tailored to meet specific filtration needs. These cartridges are often used in dust collection systems, vacuum cleaners, and industrial air filtration units. The design and efficiency of a dust cartridge can significantly impact air quality, equipment performance, and operational costs.

The primary function of dust cartridges is to trap particles as air passes through them

. Over time, dust and debris build up on the filtration media, which can lead to reduced airflow and system efficiency. Therefore, understanding the different aspects of a dust cartridge, such as its filtration performance, dust holding capacity, and maintenance requirements, is crucial for maximizing its effectiveness.One key to evaluating a dust cartridge is its filtration efficiency, often measured by a metric called the Minimum Efficiency Reporting Value (MERV). The MERV rating indicates the cartridge's ability to capture particles of varying sizes. Higher ratings indicate better filtration capabilities, allowing the cartridge to trap finer particles that can harm human health. A cartridge with a MERV rating of 13 or higher can effectively capture dust, pet dander, pollen, and even some bacteria.

dust cartridges

Another important consideration is the dust holding capacity. This defines how much dust the cartridge can contain before it becomes saturated and needs replacement or cleaning. Selecting a cartridge with an appropriate dust holding capacity for a specific application can reduce maintenance frequency and enhance operational efficiency. Properly sized cartridges help avoid unnecessary downtime and maintenance costs, which can greatly impact productivity in industrial settings.

Maintenance is a critical aspect of managing dust cartridges. Regular inspection and replacement or cleaning schedules are necessary to ensure optimal performance. Depending on the operating environment and the amount of dust generated, some cartridges may need replacement every few weeks, while others could last several months. It is vital to follow the manufacturer’s recommendations regarding maintenance intervals to ensure that the filtration system operates at peak performance.

Furthermore, the choice of dust cartridge should also consider the specific application. Different environments may generate different types of dust and contaminants. For instance, a cartridge used in a woodworking shop, where fine wood dust is prevalent, would not necessarily perform well in a food processing facility, where different contaminants may be present. Understanding these nuances can lead to informed decisions that enhance air quality control.

In conclusion, dust cartridges are crucial components in the quest for cleaner air in various settings. By effectively trapping harmful particles and contaminants, they play a significant role in protecting health and safety. When selecting dust cartridges, it’s crucial to consider factors such as filtration efficiency, dust holding capacity, and maintenance needs tailored to specific applications. Enhanced awareness and proactive management of dust cartridges can lead to improved air quality, increased operational efficiency, and ultimately, a healthier environment for all. As industries continue to evolve, the importance of effective dust filtration will only grow, making it essential for organizations to invest in quality dust cartridge solutions.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: