Tel:

+8615930870079

Tel:

+8615930870079

nov . 04, 2024 12:52 Back to list

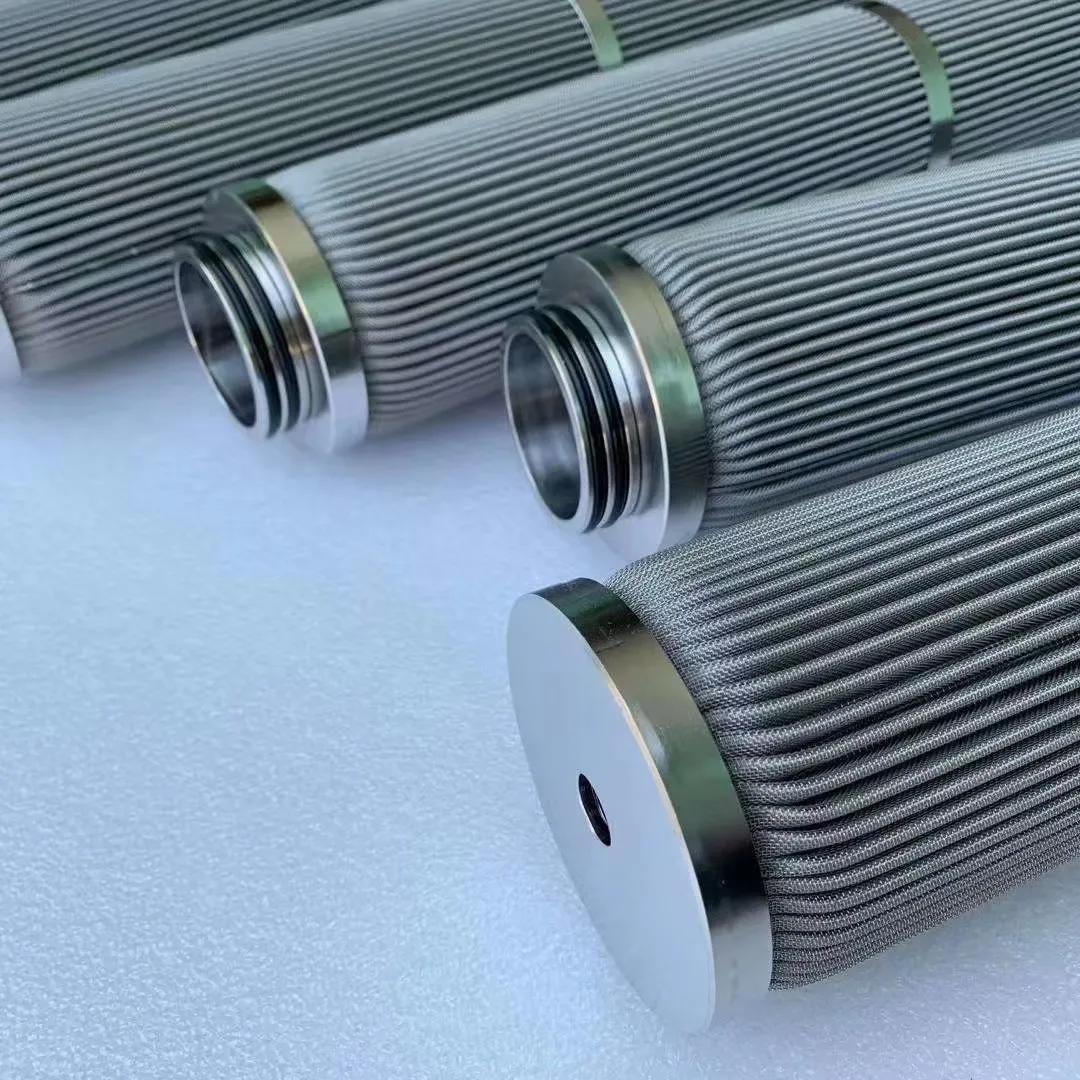

cartridge vacuum filter

Understanding Cartridge Vacuum Filters A Comprehensive Overview

Cartridge vacuum filters are integral components in various industrial applications, enabling efficient separation and filtration processes. These systems are designed to remove solids from liquids, ensuring that the final product is free from contaminants. The fundamental principle of cartridge vacuum filters relies on the application of vacuum pressure to attract liquid through a porous medium, where larger particles are captured by the filter material, while the purified liquid passes through.

Components of Cartridge Vacuum Filters

A typical cartridge vacuum filter consists of several essential components the filter cartridge, a vacuum chamber, and an inlet for the liquid to be filtered. The filter cartridge, often made from materials such as polypropylene, PTFE, or fiberglass, is the heart of the system, designed to have a large surface area for enhanced filtration efficiency. The vacuum chamber creates a pressure differential, which facilitates the flow of liquid through the cartridge while retaining solid particles.

Working Mechanism

The operation of a cartridge vacuum filter begins when the liquid mixture is introduced into the vacuum chamber

. The vacuum system generates negative pressure, drawing the liquid through the filter cartridge. As the liquid flows through the porous filter media, solids are retained on the surface and within the pores of the cartridge. This process continues until the particles build up to a point where the flow rate is reduced, indicating the need for cleaning or replacement of the cartridge.Advantages of Cartridge Vacuum Filters

cartridge vacuum filter

One of the primary advantages of cartridge vacuum filters is their versatility. They can be employed in various industries, including pharmaceuticals, food and beverage, chemical processing, and wastewater treatment. The compact design allows for easy installation and integration into existing systems. Additionally, these filters offer high filtration efficiency and can handle varying flow rates, making them suitable for different applications.

Another significant benefit is the reduced need for maintenance. The cartridge design enables easy replacement and cleaning, minimizing downtime in production processes. With advancements in filter materials, cartridge vacuum filters can achieve finer filtration and longer service life, resulting in cost savings for companies.

Applications

Cartridge vacuum filters are widely used in numerous applications. In the pharmaceutical industry, they ensure the purity of solutions and formulations by removing unwanted particles. In food and beverage processing, they help in the clarification of juices and the filtration of beer to enhance product quality and safety. Furthermore, in wastewater treatment, these filters play a crucial role in removing contaminants before effluent discharge.

Conclusion

Cartridge vacuum filters represent a reliable and efficient solution for solid-liquid separation in various industries. Their ability to provide high-quality filtration while being easy to maintain makes them a popular choice among manufacturers. As industries continue to evolve, the role of cartridge vacuum filters remains vital in ensuring product quality and operational efficiency. Understanding their design and functionality can help businesses make informed choices about their filtration needs, ultimately leading to improved processes and outcomes.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: