Tel:

+8618931101301

Tel:

+8618931101301

Dec . 20, 2024 21:13 Back to list

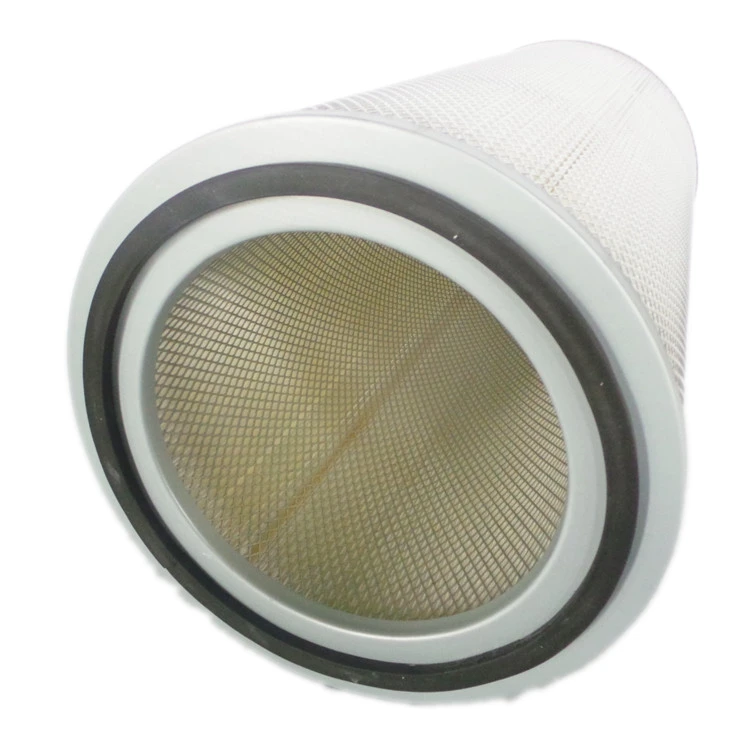

turbine filter

The Importance of Turbine Filters in Modern Engineering

In the realm of modern engineering and technology, the significance of turbine filters cannot be overstated. They play a crucial role in maintaining the efficiency, reliability, and longevity of various turbine systems, ranging from those found in power generation plants to aviation engines. Turbine filters are essential components that contribute to the overall performance of turbines by ensuring clean airflow and protecting sensitive engine parts from contamination.

Understanding Turbine Filters

Turbine filters are specialized filtration devices designed to remove unwanted particles and contaminants from the air or liquids entering a turbine system. These contaminants can include dust, dirt, water, and even biological material, which, if allowed to enter the turbine, can lead to significant wear and tear, reduced efficiency, and eventual system failure. The fundamental function of a turbine filter is to safeguard the integrity of the turbine’s operational processes, thereby ensuring optimal performance.

Types of Turbine Filters

There are various types of filters used in turbine applications, each suited to specific operational requirements. The most common types include

1. Air Filters These filters are designed to clean the air before it enters the combustion chamber of gas turbines. They often utilize pleated media or coalescing filters to capture particles as small as a few microns while allowing for efficient airflow.

2. Oil Filters In many turbine systems, lubricating oil is crucial for minimizing friction and heat. Oil filters remove contaminants from the lubricating oil, ensuring that it remains effective in protecting turbine components.

3. Fuel Filters These filters play a vital role in gas turbines, as the quality of fuel directly impacts efficiency and emissions. Fuel filters remove sediments, water, and other impurities from the fuel before combustion.

turbine filter

The Role of Turbine Filters in Performance Optimization

The performance of a turbine depends heavily on the cleanliness of the gases or liquids entering the system. Contaminants can lead to several detrimental effects, such as corrosion, erosion, and fouling. By incorporating high-quality turbine filters, companies can experience a multitude of benefits

1. Increased Efficiency Turbines operate more efficiently when the airflow and fuel supply are free from impurities. Clean input materials contribute to more complete combustion, leading to better fuel economy and less energy wasted.

2. Extended Equipment Lifespan Regular use of effective turbine filters can substantially reduce the wear on critical turbine components. By trapping harmful particles, these filters help avoid costly repairs and replacements, thereby extending the lifespan of the turbine systems.

3. Reduced Emissions With cleaner combustion processes enabled by efficient fuel filtration, turbine systems are better positioned to comply with environmental regulations. This not only benefits the planet but also helps companies avoid potential fines or sanctions associated with non-compliance.

4. Enhanced Reliability and Safety A well-maintained turbine system is less likely to experience failures. This reliability is critical in applications such as aviation, where engine failure can have catastrophic consequences. Thus, turbine filters contribute to the overall safety of operations.

Conclusion

In summary, turbine filters are an indispensable technology in the fields of energy production and aerospace engineering. Their ability to ensure clean operation significantly enhances the performance and reliability of turbine systems. With ongoing advancements in filter technology, including the development of more efficient and durable materials, the future promises even greater efficacy in protecting turbine operations. As the world continues to pursue cleaner energy sources, the role of turbine filters will be paramount in ensuring that these systems operate at peak performance, balancing the needs for efficiency, longevity, and environmental responsibility. Investing in high-quality turbine filtration solutions today is a strategic move that will yield dividends in operational reliability and cost savings for years to come.

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

-

Air filter survival guide in high-dust environmentsNewsApr.23,2025

Email:

Email: