Tel:

+8615930870079

Tel:

+8615930870079

Dec . 12, 2024 03:24 Back to list

stainless steel filter element

The Importance of Stainless Steel Filter Elements in Modern Filtration Systems

Stainless steel filter elements are becoming increasingly essential in a wide array of industries including pharmaceuticals, food and beverages, chemical processing, and oil and gas. Their unique properties and advantages make them a popular choice for filtration processes that require high performance, durability, and reliability.

Characteristics of Stainless Steel Filter Elements

Stainless steel, known for its resistance to corrosion, heat, and mechanical stress, is an ideal material for filter elements. The most commonly used grades include 304 and 316 stainless steel, each providing different levels of resistance to corrosive substances. The inherent strength of stainless steel allows for the construction of filter elements that can withstand high pressures and extreme temperatures, which is particularly beneficial in industrial applications.

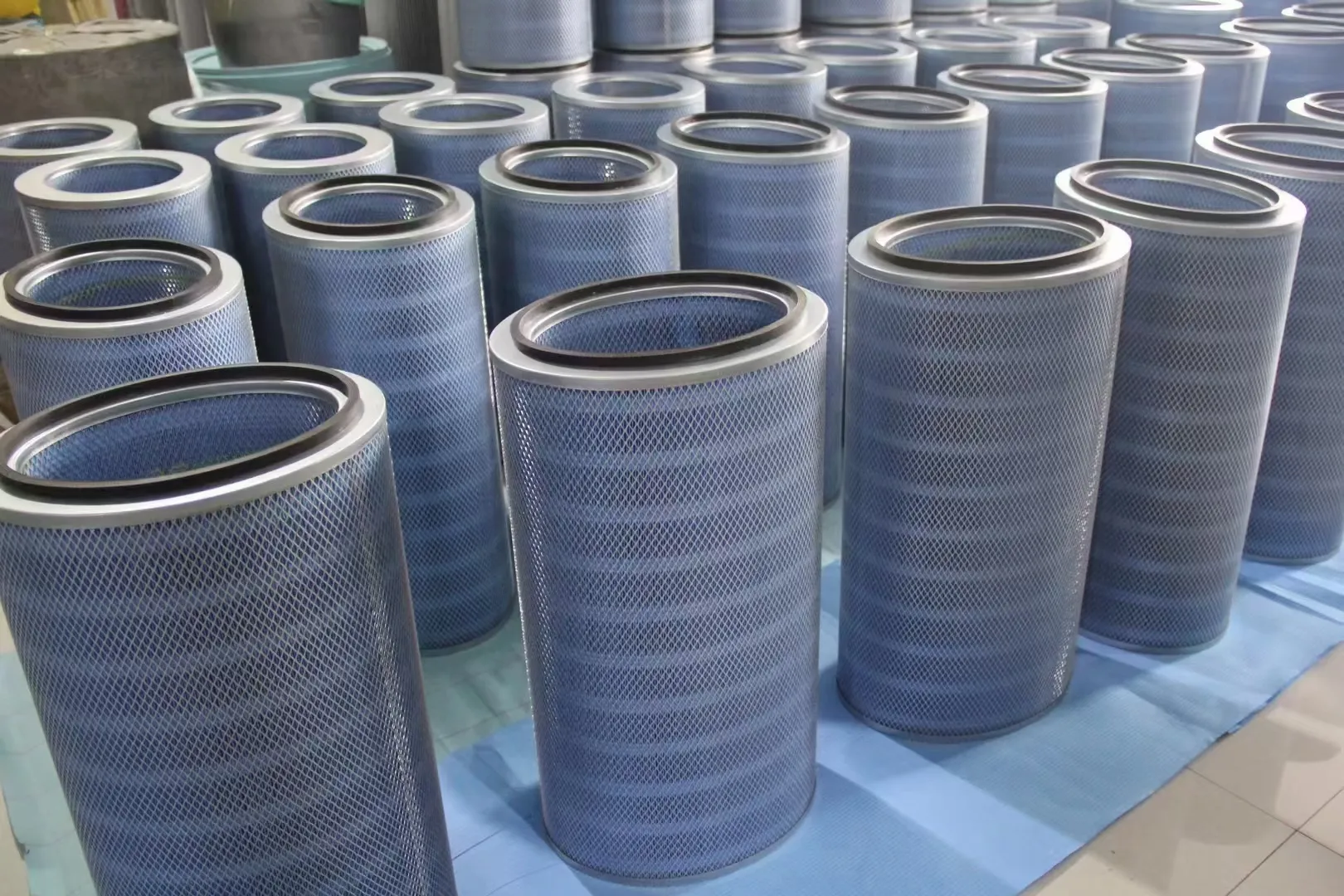

Additionally, stainless steel filter elements can be fabricated into various forms such as mesh, discs, and cartridges, offering versatility in design to meet specific filtration needs. They can effectively filter particulate matter, prevent contamination, and maintain fluid clarity, ensuring that the processes within industries run smoothly and efficiently.

Advantages of Stainless Steel Filter Elements

1. Durability and Longevity One of the most significant advantages of stainless steel filter elements is their durability. Unlike traditional paper or polypropylene filters, stainless steel can be cleaned and reused multiple times, leading to reduced replacement costs and less waste. This longevity is especially crucial in industries where downtime can be costly.

2. Chemical Resistance Stainless steel is resistant to a variety of chemicals, making it suitable for applications involving aggressive solvents and caustic materials. This feature ensures that the filter performance is not compromised over time, maintaining integrity even in harsh environments.

stainless steel filter element

3. High-Temperature Tolerance Many filtration processes operate at elevated temperatures. Stainless steel filter elements can safely handle high temperatures without deforming or losing their filtering capabilities, allowing for maximum operational efficiency.

4. Customization Stainless steel filter elements can be tailored in size, shape, and filtration ratings to meet specific application requirements. Companies can design filters that optimize performance based on the specifics of the fluid being filtered, the contaminants present, and the desired purity levels.

5. Sustainability With growing concerns about environmental sustainability, stainless steel filters offer a more eco-friendly option. Their reusable nature reduces waste, and they can be recycled at the end of their life cycle, contributing to a more sustainable business practice.

Applications of Stainless Steel Filter Elements

Stainless steel filter elements are widely used in various applications. In the food and beverage industry, they ensure cleanliness and safety of products by filtering out unwanted particles. In the chemical industry, they are crucial for processes that require high-purity solvents and reagents. In oil and gas, they help separate particulates from fluids to ensure smooth operations and protect machinery.

Conclusion

With their impressive range of benefits, stainless steel filter elements are an invaluable component in modern filtration systems. Their durability, chemical resistance, and adaptability to high-temperature environments make them an outstanding choice for industries that prioritize efficiency and quality. As technology and industrial practices continue to evolve, the demand for effective filtration solutions like stainless steel filter elements is likely to grow, underscoring their importance in maintaining the integrity of various processes across sectors. Investing in high-quality stainless steel filter elements can lead to significant long-term savings and improvements in operational efficiency, making them a wise choice for any organization committed to excellence.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: