Tel:

+8615930870079

Tel:

+8615930870079

Dec . 25, 2024 09:06 Back to list

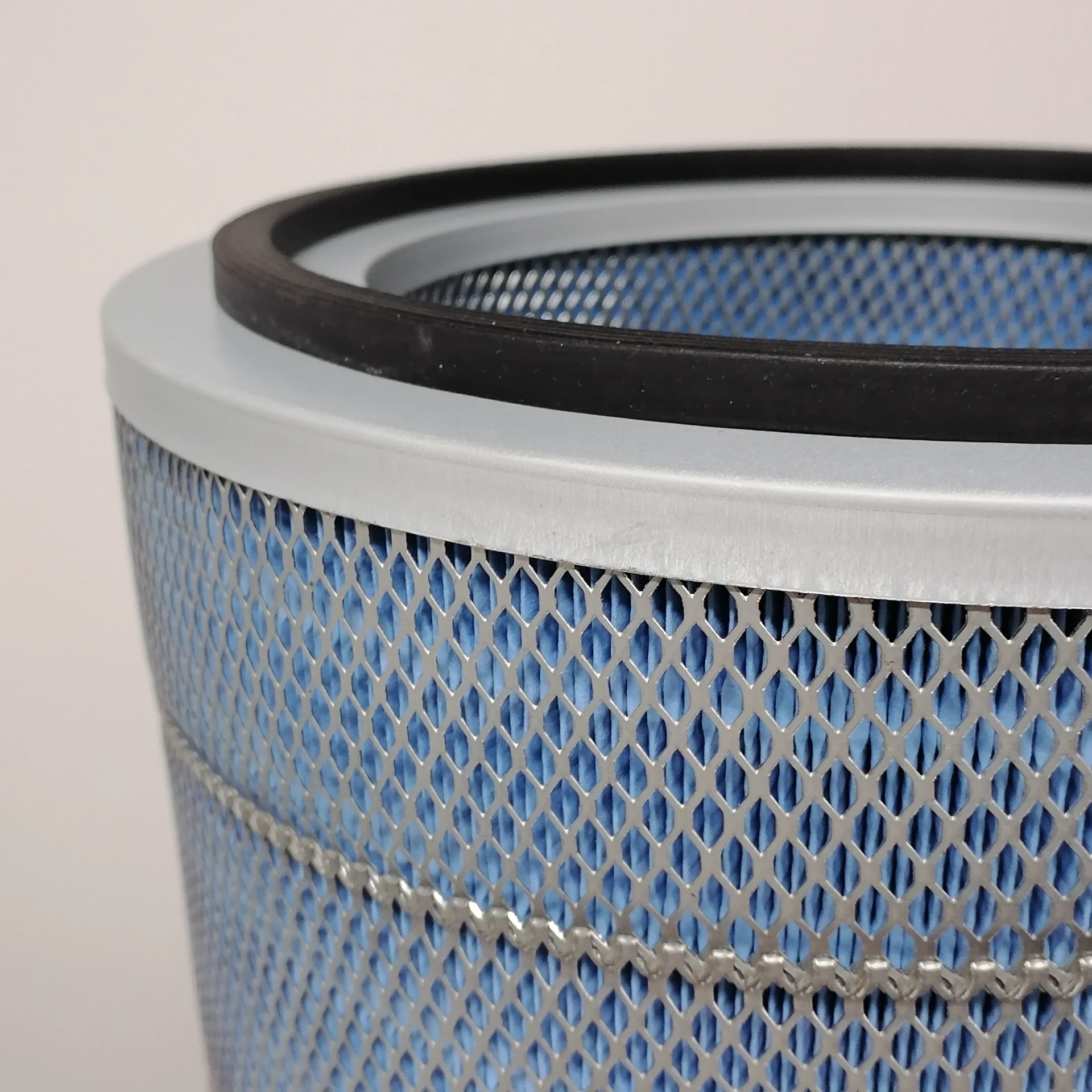

High-Efficiency Stainless Steel Sintered Filter Cartridge for Optimal Filtration Solutions

Understanding SS Sintered Filter Cartridges A Comprehensive Overview

In the world of filtration technology, SS sintered filter cartridges stand out as a prominent choice for various industrial applications. Made from stainless steel, these filter cartridges provide exceptional durability, robustness, and effectiveness in filtering a wide range of fluids, including water, oil, and chemicals. In this article, we will explore the design, advantages, applications, and maintenance of SS sintered filter cartridges.

Design and Construction

SS sintered filter cartridges are composed of stainless steel particles that are chemically bonded through a sintering process. This method involves heating the powder below its melting point until it adheres together, creating a porous material with a controlled pore size. The resulting structure allows for precise filtration while also maintaining high strength and resistance to extreme temperatures and pressures. These cartridges can be manufactured in various configurations, including cylindrical shapes and pleated designs, to suit different filtration requirements.

One of the notable features of SS sintered filters is their ability to be engineered with specific pore sizes, typically ranging from 1 to 100 microns. This versatility enables them to filter out particulates, bacteria, and larger contaminants effectively. Furthermore, due to the stainless steel material, the cartridges are not only resistant to corrosion but also withstand high flow rates, making them ideal for demanding industrial environments.

Advantages of SS Sintered Filter Cartridges

1. Durability and Longevity Unlike traditional filters made from paper or plastic, SS sintered filter cartridges have a longer service life. They can endure harsh conditions, including high temperatures and aggressive chemicals, without compromising their structural integrity.

2. Chemical Resistance Stainless steel is inherently resistant to a wide array of chemicals, making these cartridges suitable for use in various industries, including pharmaceuticals, food and beverage, petrochemical, and wastewater treatment.

3. Reusable and Cleanable SS sintered filters can be cleaned and reused multiple times, significantly reducing operational costs and waste. They can be backwashed, soaked in appropriate cleaning solutions, or mechanically cleaned to restore their filtration capabilities.

ss sintered filter cartridge

4. High Filtration Efficiency The controlled pore structure of sintered filters allows for superior filtration performance. They can effectively remove particles, sediment, and even bacteria depending on their design, ensuring cleaner and safer fluids.

5. Customizable Solutions Manufacturers can tailor SS sintered filter cartridges to meet specific requirements, such as varying dimensions, pore sizes, and configurations, making them adaptable for numerous applications.

Applications

SS sintered filter cartridges are employed in a multitude of industries due to their robust properties and effective filtering capabilities. Some common applications include

- Chemical Processing To filter solvents and other chemicals effectively while preventing contamination. - Oil and Gas In extraction and refining processes where high durability and chemical resistance are crucial. - Pharmaceuticals For ensuring the purity of products by removing unwanted particles and microbes. - Food and Beverage In applications that require hygiene and safety, such as brewing, winemaking, and juice production. - Water Treatment For municipal water supply and wastewater management, ensuring clean water is produced and contaminants are effectively removed.

Maintenance of SS Sintered Filter Cartridges

To maximize the lifespan and efficacy of SS sintered filter cartridges, regular maintenance is essential. Routine inspections should be conducted to check for blockages or excessive buildup of contaminants. Depending on the specific application and the nature of the fluid being filtered, the cleaning frequency can vary. When cleaning is necessary, appropriate methods should be employed to avoid damaging the filter medium.

In conclusion, SS sintered filter cartridges are a reliable and efficient solution for a wide range of filtration needs across various industries. Their unique design and robust characteristics provide significant advantages over traditional filter materials, making them an invaluable component of modern filtration systems. As industries continue to prioritize purification and safety, the demand for high-quality filtration solutions like SS sintered filters is bound to grow.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: