Tel:

+8615930870079

Tel:

+8615930870079

Dec . 12, 2024 01:00 Back to list

metal filter element

Understanding Metal Filter Elements A Comprehensive Overview

In the realm of industrial filtration, metal filter elements play a crucial role in various applications, particularly in sectors like oil and gas, food and beverage, pharmaceuticals, and wastewater treatment. These filter elements are designed to provide reliable and efficient filtration solutions, ensuring the purity and quality of fluids while also offering durability and longevity in demanding environments.

What are Metal Filter Elements?

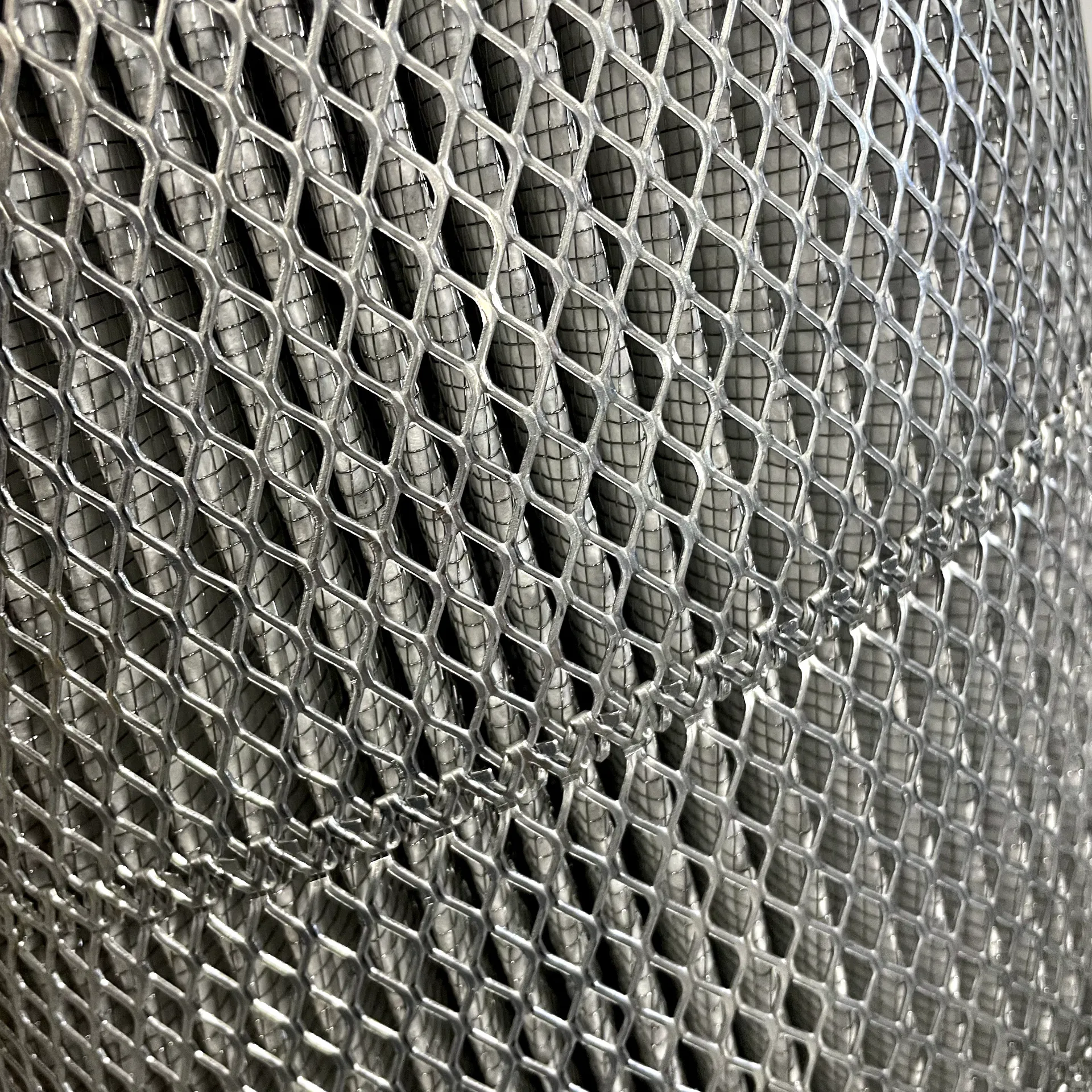

Metal filter elements are typically constructed from materials like stainless steel, bronze, or other alloys that possess excellent corrosion resistance and mechanical strength. Unlike traditional fabric or paper filters, metal filters are capable of withstanding high temperatures and pressures, making them ideal for industrial applications where performance and reliability are paramount.

These filters can be fabricated into various forms, including wire mesh, perforated plates, or sintered metal. The choice of design and construction greatly influences the filter's efficiency, dirt-holding capacity, and suitability for specific applications. Metal filters excel in situations where backwashing or cleaning is necessary, as they can be easily cleaned and reused, promoting sustainability and cost-effectiveness.

Advantages of Metal Filter Elements

One of the primary advantages of metal filter elements is their durability. Unlike their non-metal counterparts, metal filters can endure the rigors of high-flow applications without tearing or degrading, extending the lifespan of the filtration system. This durability reduces the frequency of replacements, resulting in lower operational costs and less waste generated from discarded filters.

Additionally, metal filter elements can be designed to achieve specific filtration ratings, from coarse to fine filtration, depending on the application's needs

. This versatility allows them to effectively capture contaminants ranging from larger particles to microscopic impurities, ensuring that the filtered fluid meets the necessary quality standards.metal filter element

Moreover, metal filters are capable of withstanding extreme temperatures and pressure conditions. For instance, in applications involving hot oil or steam, traditional filters may fail; however, metal filters can operate efficiently, maintaining performance and safety standards.

Applications of Metal Filter Elements

The applications for metal filter elements are vast and varied. In the oil and gas industry, these filters are often utilized for separating particulates from crude oil, ensuring the smooth operation of pipelines and refining processes. In the food and beverage sector, they can be employed to filter out foreign particles during production, contributing to product safety and quality.

In pharmaceutical manufacturing, strict regulations dictate that products must be free from contaminants. Metal filter elements can help manufacturers achieve compliance by providing a reliable means of filtration. Additionally, in wastewater treatment, they assist in removing solids from effluent streams, facilitating cleaner water discharge.

Maintenance and Cleaning

One of the standout features of metal filter elements is their ease of maintenance. Many metal filters can be cleaned using backwashing, where the flow direction is reversed to dislodge trapped particles. This process can be automated in many industrial systems, allowing for continuous operation with minimal downtime. Regular maintenance not only enhances filter longevity but also optimizes filtration efficiency.

Conclusion

In summary, metal filter elements are an invaluable component of modern industrial filtration systems. Their durability, versatility, and high-performance capabilities make them ideal for various applications, from oil refining to food production. As industries continue to prioritize quality, safety, and environmental sustainability, the significance of metal filters will only grow. Investing in metal filtration technology not only ensures reliable operation but also contributes to the overall efficiency of industrial processes. The future of filtration is undoubtedly leaning towards advanced solutions like metal filter elements, ensuring that industries can meet the challenges of tomorrow with confidence.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: