Tel:

+8618931101301

Tel:

+8618931101301

Jul . 30, 2024 19:29 Back to list

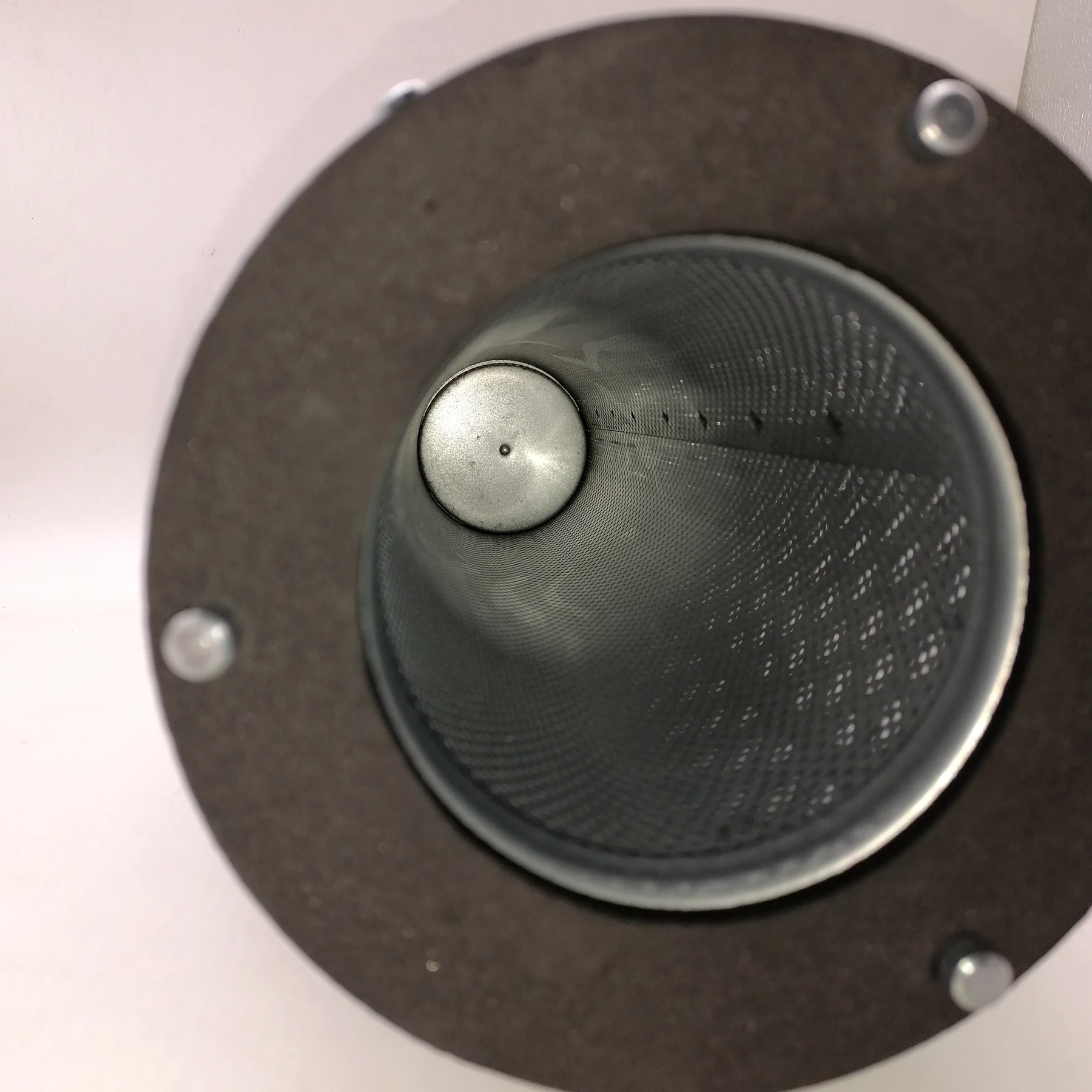

High-Efficiency Metal Filter Cartridge for Enhanced Filtration Performance and Durability in Industrial Applications

Understanding Metal Filter Cartridges Functionality and Applications

Metal filter cartridges have emerged as vital components in various industries, particularly in filtration systems. These cartridges are designed to separate solids from liquids and gases, ensuring that processes operate efficiently and that the end products meet the necessary purity standards. Their durability, high resistance to temperature and pressure, and ability to perform in harsh environments make them indispensable in numerous applications.

What Are Metal Filter Cartridges?

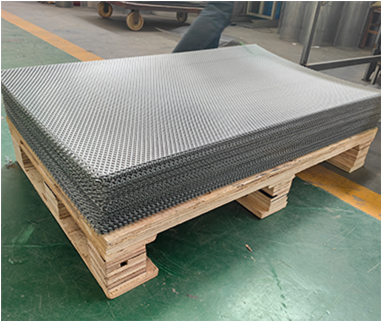

Metal filter cartridges are typically constructed from stainless steel or other metal alloys that meet specific industrial requirements. Unlike traditional paper or fabric filters, metal filters can withstand more extreme conditions, such as high temperatures and corrosive environments. Additionally, they are designed for easy cleaning and reuse, which enhances their cost-effectiveness and sustainability.

The design of metal filter cartridges can vary significantly depending on the application. Common configurations include pleated, wound, or sintered designs. Pleated designs increase the surface area, allowing for more significant filtration capacity, while sintered filters provide a porous structure that enables precise separation of very fine particles.

Key Features and Benefits

1. Durability Metal filter cartridges are known for their exceptional strength and durability. Their ability to withstand high pressures and temperatures prevents them from deforming or deteriorating during challenging operations.

2. Chemical Resistance Many metal alloys used in these cartridges are resistant to a wide range of chemicals, making them suitable for industries like petrochemicals, pharmaceuticals, and food processing.

3. Reusability One of the most significant advantages of metal filters is their reusability. They can be cleaned and recycled, reducing waste and operating costs associated with disposable filters.

4. Performance Metal filter cartridges offer superior filtration performance. They can effectively remove particulates ranging from large debris to microscopic particles, ensuring that the downstream processes remain untainted.

metal filter cartridge

5. Customization Manufacturers often offer customization options, tailoring the filtration media, cartridge size, and design to meet specific operational needs.

Applications of Metal Filter Cartridges

Metal filter cartridges are used across various sectors due to their versatility and performance. Some of the notable applications include

- Oil and Gas Industry These filters are extensively used to remove contaminants from oil and gas products, such as crude oil or natural gas. Efficient filtration is crucial for preventing equipment damage and ensuring the quality of products.

- Chemical Processing In chemical manufacturing, the need for purity is paramount. Metal filter cartridges remove impurities and particulates that could compromise product quality and safety.

- Food and Beverage Industry Metal filters ensure that food and beverage products remain uncontaminated during processing. Their ability to withstand rigorous cleaning processes makes them ideal for sanitary applications.

- Water Treatment In water purification systems, metal filter cartridges help remove sediments and other impurities, ensuring clean and safe drinking water.

Conclusion

Metal filter cartridges play a crucial role in modern filtration systems across diverse industries. Their robust design, coupled with their ability to provide exceptional filtration performance, makes them a preferred choice for many applications. As industries continue to evolve and demand higher standards of efficiency and product quality, the significance of metal filter cartridges will only increase. The transition towards sustainable practices further enhances the appeal of reusable filtering solutions like metal cartridges, reinforcing their position in the filtration landscape.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: