Tel:

+8615930870079

Tel:

+8615930870079

Nov . 10, 2024 18:57 Back to list

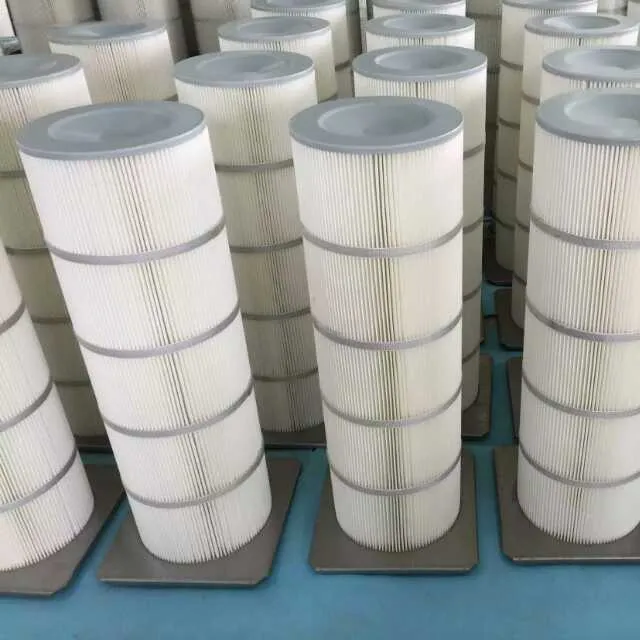

Cartridge Filters for Efficient Dust Extraction in Industrial Applications

Understanding Dust Extractor Cartridge Filters Importance, Functionality, and Maintenance

In various industrial and manufacturing environments, dust and particulate matter can pose significant risks to both equipment and employee health. As a solution, dust extractor systems play a vital role in maintaining a clean and safe workspace. Among the most effective components of these systems are cartridge filters, specifically designed to capture and contain airborne dust particles. This article explores the significance, functionality, and maintenance of dust extractor cartridge filters.

The Importance of Dust Extraction

Dust extraction is critical in numerous industries, including woodworking, metalworking, construction, and pharmaceuticals. The accumulation of dust and particulates can lead to a range of issues—from inhalation hazards for workers to damage to machinery and decreased efficiency. Effective dust extraction systems not only comply with safety regulations but also promote a healthier work environment. Recognizing the importance of dust management has led to the increasing adoption of dust extractor cartridge filters in various sectors.

How Dust Extractor Cartridge Filters Work

Dust extractor cartridge filters are designed to remove particulates from the air through a sophisticated filtering process. These filters typically consist of a cylindrical structure filled with filter media, often made from synthetic materials such as polyester or microfibers. The design allows for a large surface area, enhancing the filtration capacity while minimizing resistance to airflow.

As dirty air is pulled into the dust extractor system, it passes through the cartridge filter, where particles are captured by the filter media. The clean air is then returned to the environment or recirculated back into the workspace. One of the key advantages of cartridge filters is their ability to provide high filtration efficiency while maintaining a lower pressure drop compared to other filter types.

The Benefits of Cartridge Filters

1. High Filtration Efficiency Cartridge filters are designed to capture a wide range of particulate sizes, enhancing indoor air quality and ensuring compliance with occupational health standards.

2. Extended Service Life Due to their large surface area, cartridge filters can hold a significant amount of dust before requiring replacement. This results in longer service life and less frequent filter changes compared to traditional bag filters.

dust extractor cartridge filter

3. Space Efficiency The compact design of cartridge filters makes them suitable for environments with limited space. They can be integrated into existing ductwork systems or standalone dust collection units.

4. Easy Maintenance Many modern dust extractor systems are equipped with self-cleaning mechanisms, allowing for easy maintenance of the cartridge filters. This feature ensures consistent performance and minimizes downtime.

Maintenance of Dust Extractor Cartridge Filters

Proper maintenance is essential for ensuring the optimal performance of dust extractor cartridge filters. Here are some key maintenance practices

1. Regular Inspection Schedule periodic inspections to check for any visible wear or damage to the filter cartridges. Look for signs of clogging or excessive dust buildup.

2. Cleaning Utilize the self-cleaning functions, if available, to dislodge dust from the cartridge filters. Alternatively, manual cleaning can be performed using compressed air or specialized cleaning equipment.

3. Replacement Be aware of the recommended replacement intervals for the cartridge filters. Factors such as the type of material being processed and the volume of dust generated can influence how often filters need to be changed.

4. Documenting Maintenance Activities Keep accurate records of inspections, cleaning, and replacements. This documentation can help in scheduling future maintenance and ensuring compliance with safety regulations.

Conclusion

Dust extractor cartridge filters are an essential component of effective dust management systems in various industries. Their high filtration efficiency, space-saving design, and ease of maintenance make them a preferred choice for many businesses aiming to enhance air quality and protect their workforce. By understanding the functionality and importance of these filters and implementing a regular maintenance routine, companies can significantly improve workplace safety and productivity.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: