Tel:

+8618931101301

Tel:

+8618931101301

11월 . 29, 2024 14:38 Back to list

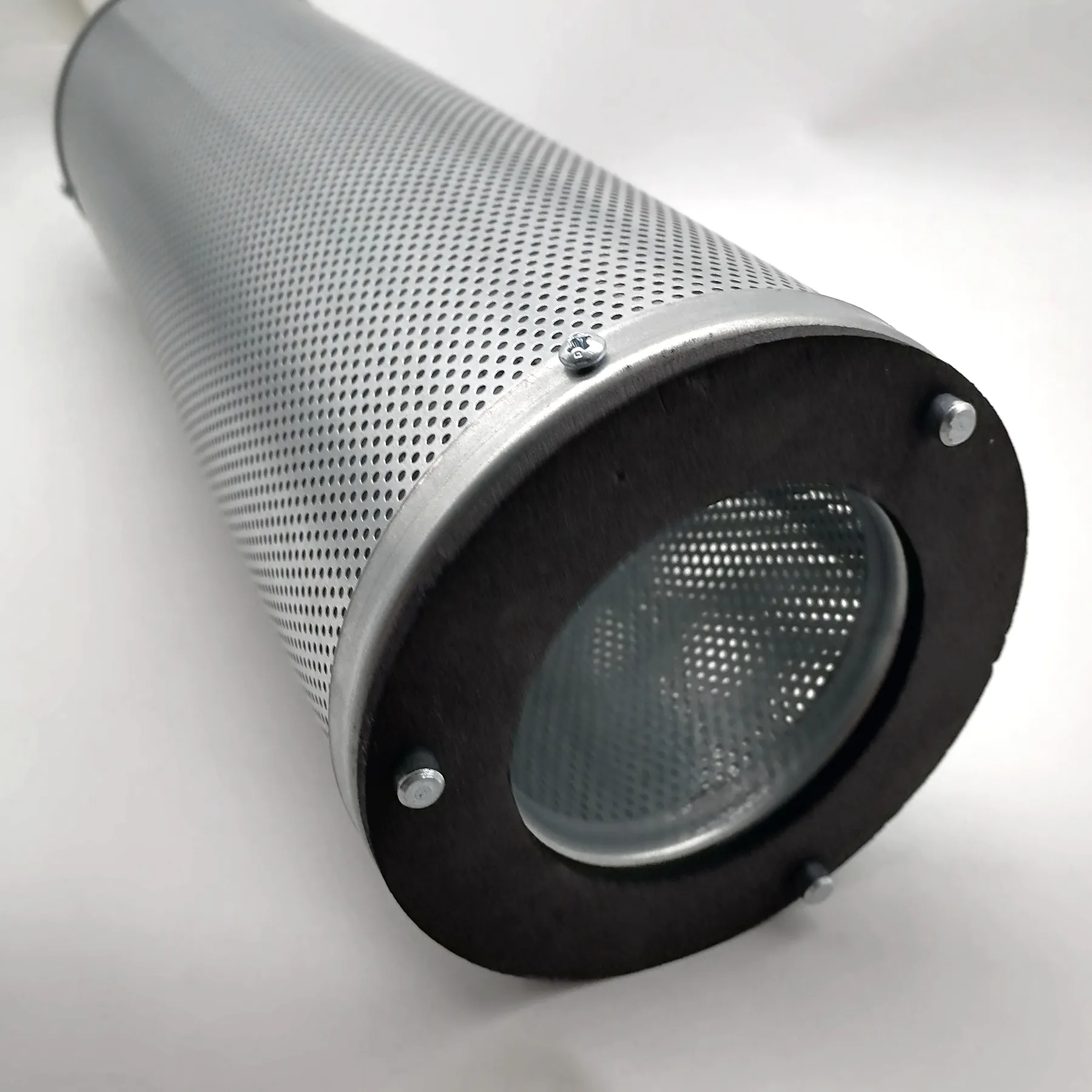

High-Performance Pleated Filter Cartridge for Efficient Liquid Filtration Solutions

Understanding SS Pleated Filter Cartridges A Comprehensive Overview

In today's industrial landscape, the importance of effective filtration cannot be overstated. Among the most efficient filtration solutions available are stainless steel (SS) pleated filter cartridges. These cartridges play a crucial role in various applications, providing exceptional performance, durability, and reliability. In this article, we will delve into what SS pleated filter cartridges are, their benefits, applications, and maintenance considerations.

What Are SS Pleated Filter Cartridges?

SS pleated filter cartridges are filtration devices made from high-quality stainless steel, designed to capture particles and contaminants from liquids and gases. The pleated design increases the surface area available for filtration, allowing for higher dirt-holding capacity and extended service life. These cartridges are often used in critical processes where purity and consistency are paramount.

Benefits of Stainless Steel Pleated Filter Cartridges

1. Durability One of the most significant advantages of SS pleated filter cartridges is their durability. Stainless steel is resistant to corrosion, oxidation, and extreme temperatures, making these cartridges suitable for harsh environments. This longevity translates to lower replacement costs and reduced downtime for maintenance.

2. High Filtration Efficiency The pleated design of these cartridges enhances their filtration efficiency. The increased surface area allows for the capture of smaller particles, ensuring that the output is of a higher purity level. This is crucial in applications such as pharmaceuticals, food and beverage, and chemical processing, where contaminants can compromise product quality.

3. Reusability Unlike disposable filters, stainless steel cartridges can be cleaned and reused multiple times. This not only makes them an environmentally friendly option but also helps in cutting operational costs associated with purchasing new filters.

4. Versatility SS pleated filter cartridges are available in various pore sizes and configurations, making them suitable for a wide range of applications. Whether it’s liquid filtration or air purification, these cartridges can be tailored to meet specific requirements.

ss pleated filter cartridge

5. Easy Maintenance Maintenance of SS pleated filter cartridges is relatively straightforward. They can be cleaned using various methods such as backwashing, chemical cleaning, or manual scraping. This ease of maintenance enables operators to ensure optimal performance without extensive downtime.

Applications

SS pleated filter cartridges find applications in diverse industries, including

- Pharmaceuticals Ensuring the purity of drugs and active ingredients by removing contaminants. - Food and Beverage Filtering out unwanted particles to maintain product quality and safety. - Chemical Processing Protecting sensitive equipment from particulates that could affect the manufacturing process. - Oil and Gas Removing solid contaminants from fluids to ensure efficient operation of systems.

Maintenance Considerations

To maximize the lifespan and efficiency of SS pleated filter cartridges, regular maintenance is essential. Operators should develop a routine schedule for checking the condition of the cartridges and cleaning them as required. Monitoring pressure differentials can help indicate when a cartridge needs maintenance or replacement. Additionally, understanding the specific requirements of the application will guide effective maintenance practices.

Conclusion

In conclusion, SS pleated filter cartridges stand out as a vital component in industrial filtration, providing numerous benefits such as durability, efficiency, and versatility. Their unique design and material properties make them suitable for a wide range of applications, ensuring high levels of filtration performance. As industries continue to prioritize quality and efficiency, the role of stainless steel pleated filter cartridges will undoubtedly remain significant, contributing to improved processes and product integrity. Investing in these advanced filtration solutions is a step towards achieving operational excellence and sustainability in various sectors.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: