Tel:

+8615930870079

Tel:

+8615930870079

9월 . 19, 2024 05:39 Back to list

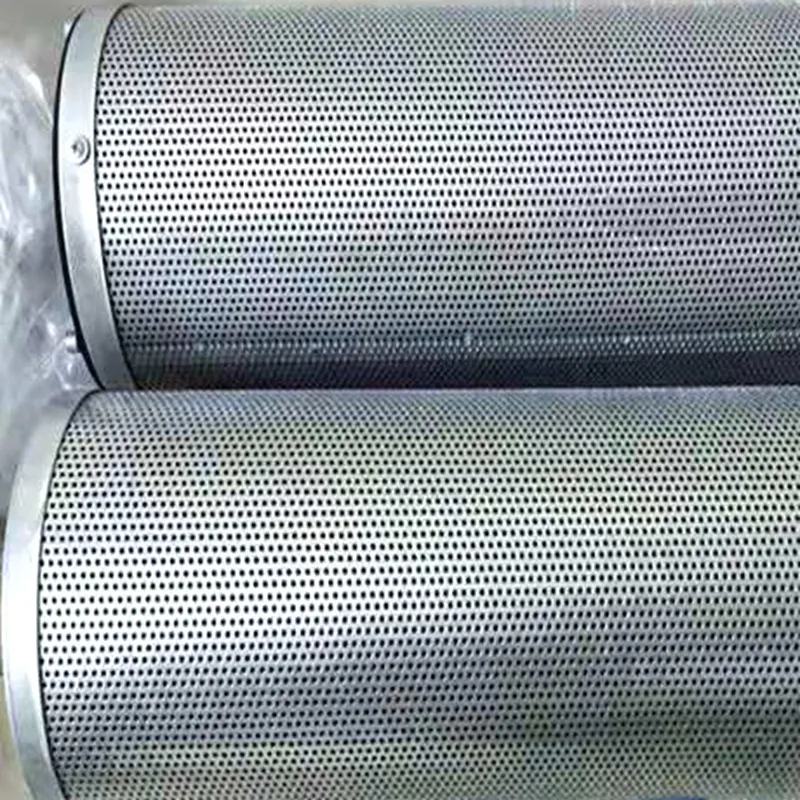

metal filter element

Understanding Metal Filter Elements Key Features and Applications

Metal filter elements play a crucial role in various industries, providing efficient filtration solutions for a broad range of applications. These filters are designed to remove impurities and solid particles from gases and liquids, ensuring the purity and quality of the final product. Unlike conventional filters made from paper or synthetic materials, metal filter elements offer superior durability, thermal resistance, and versatility, making them an increasingly popular choice in demanding environments.

One of the primary advantages of metal filter elements is their robustness. Constructed from high-quality metals such as stainless steel, these filters can withstand extreme temperatures and pressures, making them ideal for use in harsh conditions. This durability not only extends the life of the filter but also reduces the need for frequent replacements, resulting in lower maintenance costs over time.

Metal filter elements also boast excellent mechanical strength and are resistant to corrosion, oxidation, and other forms of wear, which can occur in aggressive environments. Their ability to maintain structural integrity under various conditions allows them to perform consistently, ensuring that the filtration process remains effective and reliable.

metal filter element

In terms of filtration efficiency, metal filters provide a high level of particle retention with minimal pressure drop. The design of metal filter elements can be tailored to meet specific filtration requirements, allowing for the removal of particulates down to very fine sizes. This versatility enables their use in diverse applications, from food and beverage processing to chemical production and aerospace, where purity is paramount.

Another key feature of metal filter elements is their ease of cleaning and reusability. Unlike disposable filters that must be replaced after a single use, metal filters can be cleaned through various methods such as backflushing, ultrasonic cleaning, or even chemical cleaning, depending on the application. This reusability not only contributes to sustainability efforts by reducing waste but also provides a cost-effective filtration solution over time.

The customization of metal filter elements is another highlight for industries with specific needs. Manufacturers can design filters with various pore sizes, shapes, and configurations, catering to the unique demands of each application. Whether it's a simple cylindrical filter or a complex multi-layer design, versatility in manufacturing allows for tailored solutions that optimize performance.

In conclusion, metal filter elements serve as essential components in industrial processes, offering a range of benefits including durability, efficiency, and reusability. As industries continue to evolve and face new challenges, the demand for reliable filtration solutions will only grow, making metal filter elements a vital consideration for engineers and manufacturers alike. With their ability to maintain performance under extreme conditions, they stand out as a top choice for advanced filtration needs in modern applications.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: