Tel:

+8615930870079

Tel:

+8615930870079

11월 . 28, 2024 19:48 Back to list

Gas Turbine Inlet Filter Maintenance and Performance Optimization Techniques

The Importance of Gas Turbine Inlet Filters

Gas turbines have become an integral part of modern energy generation, providing efficient and reliable power for various applications, including electricity production and aircraft propulsion. However, the performance and longevity of gas turbines can be significantly impacted by the quality of the air that enters them. This is where gas turbine inlet filters come into play.

Understanding Gas Turbine Inlet Filters

Gas turbine inlet filters are designed to improve the quality of the air entering the turbine, ensuring that it is free from contaminants that can lead to damage and inefficiencies. The primary function of these filters is to capture dust, dirt, pollen, and other particulate matter that could potentially harm the turbine's components. Given that the operational efficiency of gas turbines is closely tied to the cleanliness of the inlet air, these filters are crucial to maintaining optimal performance.

Types of Inlet Filters

There are several types of inlet filters used in gas turbine applications. The most common types include

1. Panel Filters These are flat filters made from various filter media, capable of capturing larger particles. They are often the first line of defense against contaminants and are easy to replace.

2. Pleated Filters Equipped with pleated surfaces, these filters provide a larger surface area for trapping particles while maintaining low resistance to airflow. They are effective for capturing fine dust, providing a balance between filtration efficiency and airflow.

3. Bag Filters These filters consist of a series of fabric bags that can capture larger volumes of particulates. Bag filters are typically used in environments with high levels of airborne debris.

4. Heat Recovery Filters In some cases, heat recovery systems are integrated with gas turbine filters to pre-heat the inlet air, improving efficiency while also filtering contaminants.

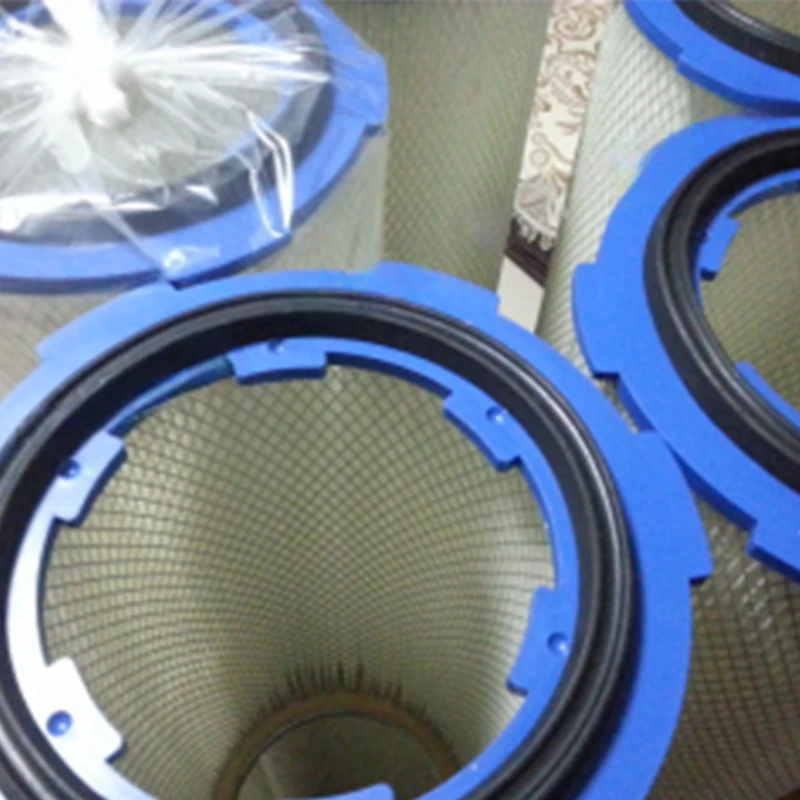

gas turbine inlet filter

Benefits of Inlet Filtration

1. Enhanced Performance Clean air significantly improves gas turbine efficiency and performance. Contaminants can disrupt combustion processes, leading to decreased output and increased fuel consumption.

2. Reduced Downtime Regular maintenance of inlet filters helps prevent turbine failures. By keeping the air clean, gas turbine operators can reduce unplanned downtime due to repairs or component replacements.

3. Extended Equipment Life By preventing contaminants from entering the turbine, inlet filters help extend the life of critical components such as blades, combustion chambers, and bearings. This leads to lower maintenance costs and a higher return on investment.

4. Environmental Impact Gas turbines that operate efficiently emit fewer greenhouse gases and pollutants. Ensuring the inlet air quality allows operators to meet regulatory requirements while contributing to sustainability efforts.

Challenges and Considerations

While the benefits of gas turbine inlet filters are clear, operators must also consider certain challenges. For example, filters can become clogged over time, which may restrict airflow and hinder performance. Therefore, regular maintenance and timely replacement are critical to ensuring optimal operation.

Additionally, the choice of filter media is influenced by the specific environmental conditions in which the turbine operates. For example, turbines located in desert regions may require more robust filtration solutions to handle high levels of dust, while those in industrial areas might need filters capable of capturing chemical particulates.

Conclusion

Gas turbine inlet filters play a vital role in the performance and reliability of gas turbines. By ensuring the air entering the turbine is free of harmful contaminants, these filters help optimize efficiency, reduce maintenance costs, and extend equipment life. Given the increasing demand for clean and sustainable energy sources, the importance of maintaining high air quality through effective filtration cannot be overstated. As technology continues to advance, the evolution of inlet filter designs and materials will further enhance the capabilities and environmental performance of gas turbines, paving the way for a cleaner and more energy-efficient future. Operators must remain vigilant in keeping up with maintenance schedules and filter replacements to fully capitalize on these benefits and ensure the longevity of their gas turbine systems.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: