ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

2월 . 18, 2025 02:31 Back to list

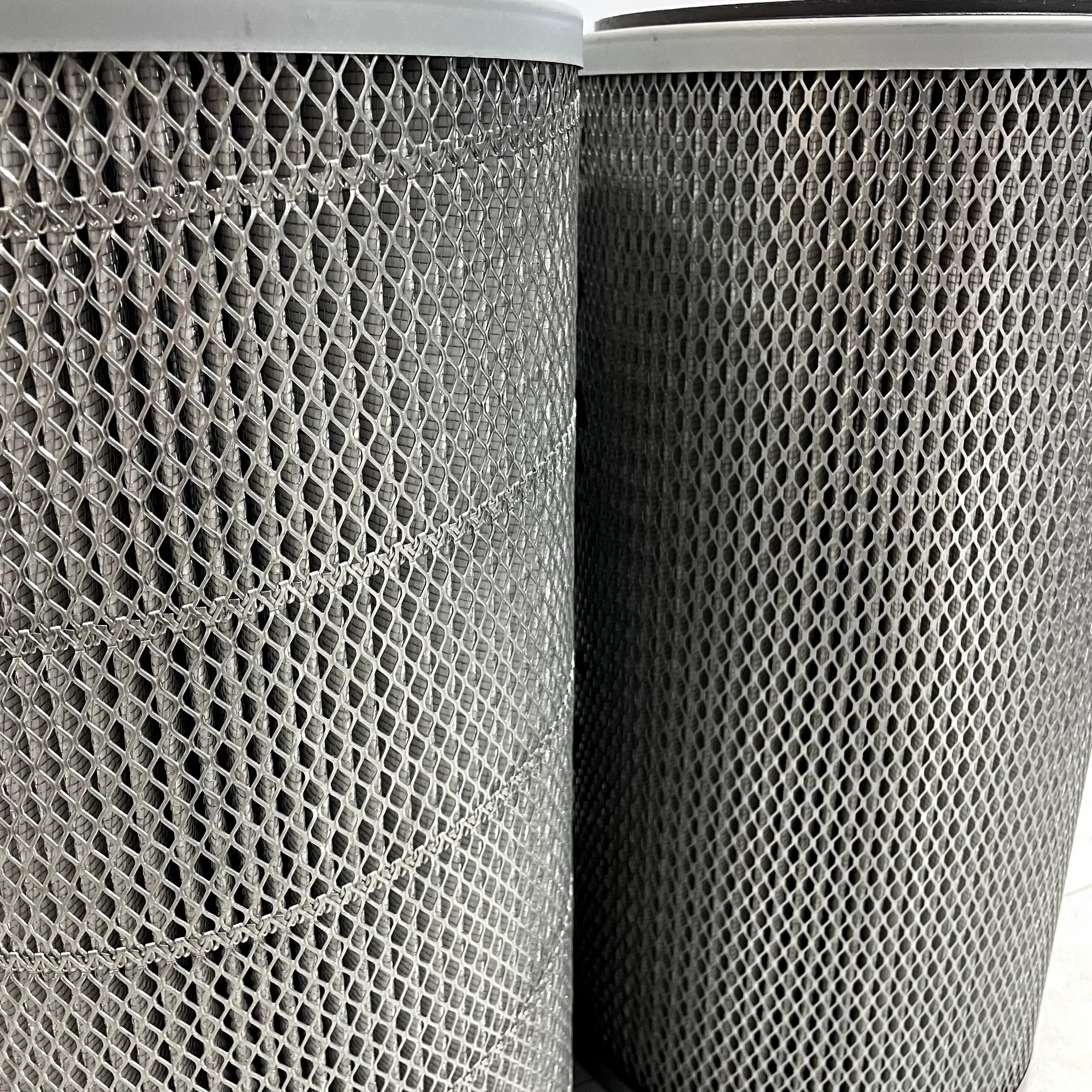

Cylindrical Gas Turbine Air Intake Filter Manufacturer Conical Air Filter Cartridge

Gas turbines power everything from aircraft engines to electricity generators and are at the heart of many industrial processes. Their performance and efficiency are directly influenced by external factors like air quality. When it comes to maintaining optimal conditions, the gas turbine inlet filter is a critical component that ensures turbines operate smoothly. Based on real-world experience, expertise from leading manufacturers, authoritative insights, and trustworthy data, choosing the right inlet filter can significantly impact your turbine’s efficiency and longevity.

Moreover, the authoritativeness associated with specific brands in gas turbine inlet filters cannot be overlooked. Few manufacturers have consistently set the benchmark in the industry through rigorous testing and demonstrating unmatched efficiency in challenging environments. Trust is built, not only through performance guarantees but also via certifications and compliance with international standards. For instance, reputable manufacturers undergo stringent third-party testing to verify the efficacy and reliability of their filter products. In practice, the installation and maintenance of turbine inlet filters require technical expertise and knowledge of the unique requirements of different turbine setups. Those operating in areas prone to high levels of pollution or saline exposure, such as coastal regions, must seek consultancy from professionals with proven expertise in dealing with harsh environments. Trusted service providers offer comprehensive support, from selection to installation and regular maintenance advice, ensuring turbines achieve peak performance regardless of the environmental conditions. In summary, the gas turbine inlet filter is a crucial investment for businesses relying on gas turbines for their operations. Experience from industry leaders and insights from field experts validate the necessity of choosing high-performance filtration solutions. Each component's design, material choice, and manufacturer reputation play a significant role in determining the long-term success of a turbine. Businesses must evaluate their specific needs, environmental challenges, and operational goals to select the most suitable filtration system. By trusting in the expertise and authoritative recommendations of seasoned professionals, industries can safeguard the performance and efficiency of their turbines, ensuring operational excellence and economic efficiency.

Moreover, the authoritativeness associated with specific brands in gas turbine inlet filters cannot be overlooked. Few manufacturers have consistently set the benchmark in the industry through rigorous testing and demonstrating unmatched efficiency in challenging environments. Trust is built, not only through performance guarantees but also via certifications and compliance with international standards. For instance, reputable manufacturers undergo stringent third-party testing to verify the efficacy and reliability of their filter products. In practice, the installation and maintenance of turbine inlet filters require technical expertise and knowledge of the unique requirements of different turbine setups. Those operating in areas prone to high levels of pollution or saline exposure, such as coastal regions, must seek consultancy from professionals with proven expertise in dealing with harsh environments. Trusted service providers offer comprehensive support, from selection to installation and regular maintenance advice, ensuring turbines achieve peak performance regardless of the environmental conditions. In summary, the gas turbine inlet filter is a crucial investment for businesses relying on gas turbines for their operations. Experience from industry leaders and insights from field experts validate the necessity of choosing high-performance filtration solutions. Each component's design, material choice, and manufacturer reputation play a significant role in determining the long-term success of a turbine. Businesses must evaluate their specific needs, environmental challenges, and operational goals to select the most suitable filtration system. By trusting in the expertise and authoritative recommendations of seasoned professionals, industries can safeguard the performance and efficiency of their turbines, ensuring operational excellence and economic efficiency.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: