Tel:

+8615930870079

Tel:

+8615930870079

10월 . 04, 2024 01:42 Back to list

gas turbine air intake filter manufacturers

Gas Turbine Air Intake Filter Manufacturers A Critical Component in Modern Power Generation

Gas turbines play a crucial role in the generation of electricity, propulsion, and various industrial applications. One of the key components that significantly influence the efficiency and performance of gas turbines is the air intake filter. This article will explore the importance of gas turbine air intake filters and highlight some notable manufacturers in this specialized field.

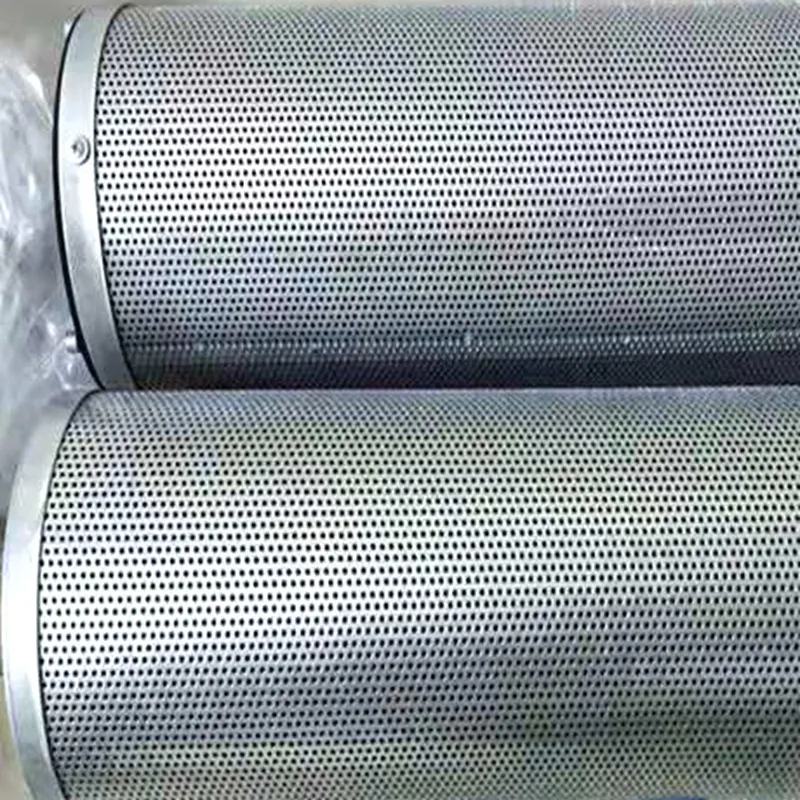

The primary function of an air intake filter in gas turbines is to remove pollutants, contaminants, and particulates from the ambient air before it enters the turbine's combustion system. This is essential because any foreign particles such as dust, sand, or other debris can cause significant damage to the turbine, leading to decreased performance, increased maintenance costs, and even catastrophic failures. Therefore, having a high-quality air intake filter is vital for ensuring the operational integrity and longevity of gas turbine systems.

There are various types of air intake filters used in gas turbines, including mechanical filters, electrostatic filters, and HEPA filters, among others. Each type has its own unique properties and advantages, allowing manufacturers to tailor their products to meet the specific requirements of different applications and environments. For instance, in coastal regions where salt and moisture are prevalent, manufacturers often design filters that can resist corrosion while maintaining high filtration efficiency.

gas turbine air intake filter manufacturers

Several leading manufacturers specialize in producing air intake filters for gas turbines. One prominent name is Parker Hannifin, which offers a wide range of filtration solutions designed to enhance turbine performance. Their filters are known for their durability, efficiency, and ability to handle high flow rates. Parker Hannifin also emphasizes innovation in filter design, employing advanced materials that improve filtration without compromising airflow.

Another significant player in this sector is Camfil, a global leader in air filtration systems. Camfil focuses on developing filters that provide both high efficiency and low pressure drop, thereby ensuring optimal performance for gas turbines. Their products are engineered to withstand harsh environmental conditions, making them suitable for a variety of installations, from power plants to industrial facilities.

Donaldson Company, Inc. is also a key manufacturer of gas turbine air intake filters. They offer a comprehensive range of filters that are designed to maximize the operational reliability of turbines. Donaldson's products undergo rigorous testing to ensure they meet industry standards for filtration efficiency and durability, especially in demanding environments.

In summary, gas turbine air intake filters are essential for maintaining the efficiency and reliability of turbine systems. Manufacturers like Parker Hannifin, Camfil, and Donaldson Company have emerged as leaders in this field, providing innovative filtration solutions that not only protect the turbine but also contribute to overall energy efficiency. As the demand for cleaner and more efficient energy production continues to grow, the role of high-quality air intake filters will only become more critical in the operation of gas turbines. With ongoing advancements in materials and technologies, the future of gas turbine filtration appears promising, ensuring that these engines can perform optimally in an ever-changing landscape.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: