Tel:

+8615930870079

Tel:

+8615930870079

11월 . 23, 2024 01:22 Back to list

gas turbine air intake filter

The Importance of Air Intake Filters in Gas Turbines

Gas turbines are a crucial component of modern power generation systems and are widely utilized in aviation, marine, and industrial applications. They rely on the efficient conversion of fuel into energy, making the integrity of their performance paramount. One of the key aspects of maintaining optimal gas turbine operation is the air intake filter system. In this article, we will explore the significance of air intake filters in gas turbines, their functioning, and the impact of their efficiency on overall turbine performance.

Understanding the Role of Air Intake Filters

Every gas turbine requires a consistent flow of clean air for effective combustion. This air needs to be filtered to prevent contaminants—such as dust, sand, and other particulates—from entering the combustion chamber. These contaminants can cause erosion, corrosion, and fouling of the turbine blades, which can lead to reduced efficiency, increased maintenance costs, and ultimately, a decrease in the lifespan of the turbine.

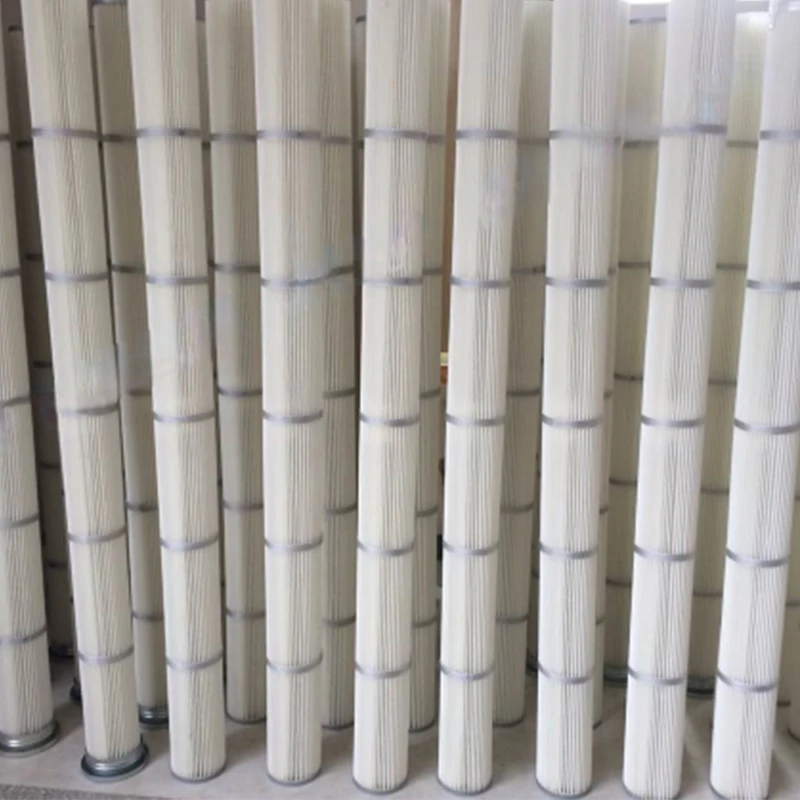

Air intake filters serve as the first line of defense against these harmful particles. They are designed to remove solid and liquid impurities from the intake air, allowing only clean air to mix with the fuel for the combustion process. Depending on the specific application and operating environment, different types of filters, such as dry filters, wet filters, and electrostatic filters, may be employed.

Types of Air Filters

1. Dry Filters These are the most common types of filters used in gas turbines. They consist of synthetic or fiberglass materials that capture particulates through mechanical filtration. Dry filters are lightweight and can handle varying air flow conditions, making them ideal for many applications.

2. Wet Filters These filters utilize a liquid medium to trap contaminants. They are particularly effective in environments where water or moisture is prevalent, as they can also remove water droplets from the air, thus protecting the turbine from hydrocarbon contamination.

3. Electrostatic Filters These filters use electrostatic forces to attract and trap particles. They can be very effective in removing fine particulates that might pass through conventional dry filters. However, they require a consistent power source and maintenance to ensure they operate effectively.

gas turbine air intake filter

The Impact of Filter Efficiency

The efficiency of air intake filters directly influences the performance and reliability of gas turbines. High-efficiency filters can significantly reduce the amount of harmful particles entering the turbine. This can lead to improved combustion efficiency, resulting in higher power output and lower fuel consumption. In contrast, a poorly maintained or inefficient filter can lead to increased wear and tear on engine components, necessitating more frequent maintenance and repairs.

Moreover, filters that are not properly managed can become clogged, which impedes airflow. Restricted airflow can reduce turbine efficiency and lead to overheating, further jeopardizing turbine operation. Turbine operators must regularly monitor filter performance, replace old or clogged filters, and optimize filter selection based on specific environmental conditions.

Maintenance and Best Practices

To ensure the longevity and performance of gas turbines, it is vital to adopt best practices in air intake filter maintenance. Regular inspections should be conducted to assess filter conditions, and a replacement schedule should be established based on operating conditions and manufacturer recommendations.

Operators should consider implementing predictive maintenance practices. Utilizing pressure drop measurements across the filters can provide insights into their condition and indicate when replacement is necessary. Additionally, incorporating data analytics and machine learning algorithms can help predict filter performance, optimizing maintenance schedules and reducing unexpected downtime.

Conclusion

In summary, air intake filters play a vital role in ensuring the efficiency and longevity of gas turbines. By delivering clean air to the combustion process, these filters protect turbine components from harmful contaminants and assist in maintaining optimal operational performance. As the energy industry continues to evolve, the integration of advanced filter technologies and maintenance practices will remain crucial in maximizing the effectiveness of gas turbines, contributing to more sustainable and reliable energy production.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: