전화:

+8615930870079

전화:

+8615930870079

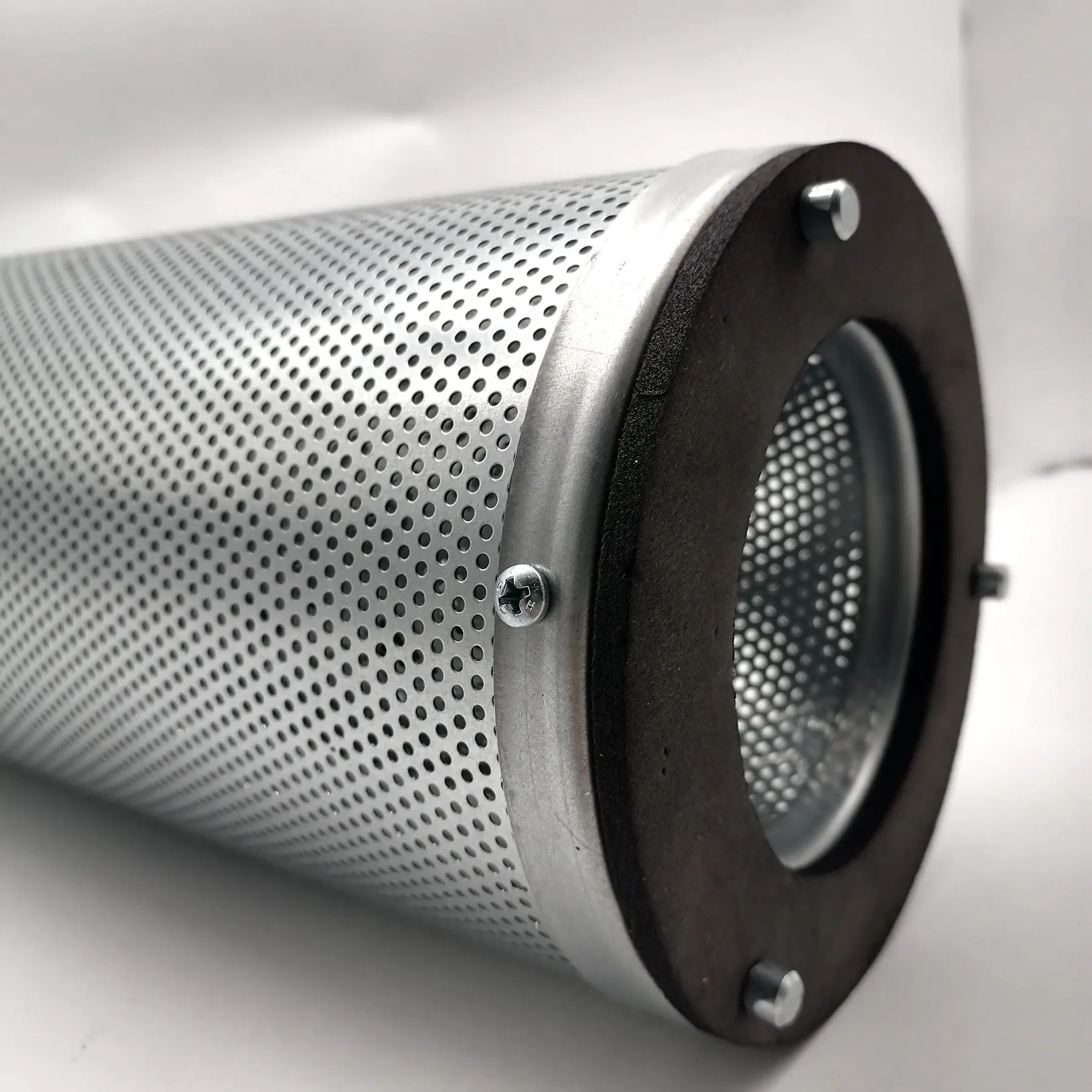

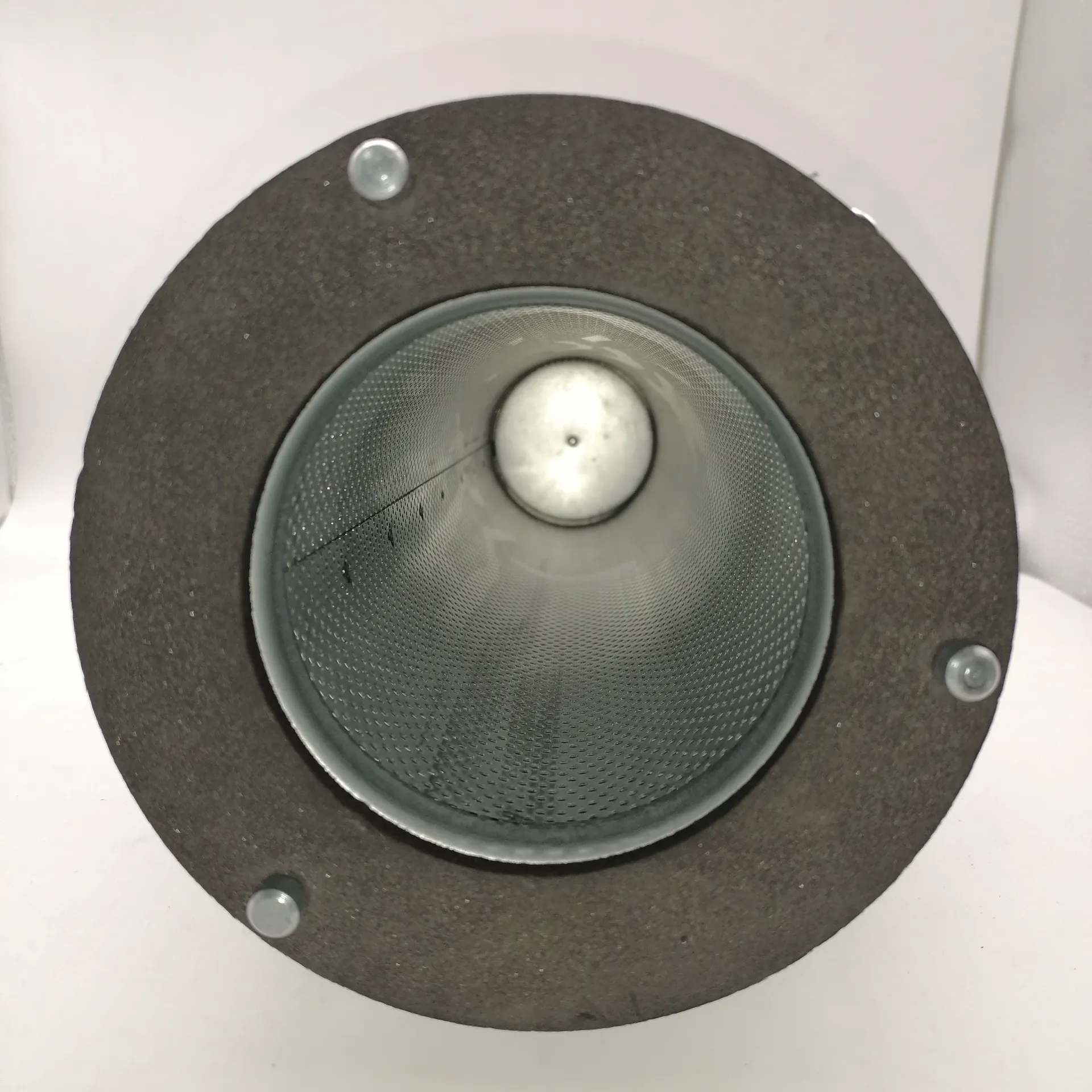

활성화 된 탄소 필터 카트리지는 주로 유기 증기, 냄새, 연기 및 유해 가스와 같은 오염 물질을 흡착하고 제거하는 데 주로 공기 정제 성분입니다. 핵심 재료는 활성화 된 탄소, 고도로 발달 된 기공 구조와 넓은 특이 적 표면적을 갖는 특수 처리 된 탄소 질 물질로 강력한 흡착 능력을 제공합니다.

활성화 된 탄소 필터 카트리지의 작동 원리는 활성탄의 물리적 흡착 및 화학적 흡착 메커니즘을 기반으로합니다. 물리적 흡착은 다공성 구조를 통해 공기 중의 오염 물질을 활성화 된 탄소 포획을 말하는 반면, 화학 흡착은 활성탄 및 오염 물질 표면의 화학 그룹 간의 반응을 포함한다. 이 이중 흡착 메커니즘을 통해 활성화 된 탄소 필터 카트리지는 공기 중 유해 물질을 제거하는 데 우수한 성능을 나타냅니다.

활성탄 필터 카트리지는 광범위한 응용 분야에서 사용되며 일반적으로 산업용 환기 시스템, 실험실, 의료 시설, 사무실 및 주택에 사용됩니다. 이러한 환경에서 활성화 된 탄소 필터 카트리지는 대기 질을 향상시키고 사람들의 건강을 보호하는 데 도움이되며 특정 산업의 공기 정화에 대한 엄격한 표준을 충족시키는 데 도움이됩니다.

=== 성능 특징 ===

◆ 특수 화학식으로 처리 된 세분화 활성탄 사용

◆ 강력한 흡착 용량, 높은 제거 효율 및 안정적인 성능

◆ 설치 및 유지 관리, 낮은 운영 비용

◆ 교체 가능한 흡착 매체, 금속 쉘을 재사용 할 수 있습니다.

◆ 프레임은 필요한 가스 처리 용량에 따라 제공 및 조립 및 사용할 수 있습니다.

◆ 필터 카트리지 재료는 아연 도금 강판 또는 스테인레스 스틸 일 수 있습니다.

◆프레임 재질은 냉간 압연 강판 스프레이 코팅 또는 스테인리스 스틸일 수 있습니다.

=== 응용 프로그램 ===

◆공기중의 냄새(악취) 및 유해가스를 제거하기 위한 상업용 또는 산업용 중앙공조장치 및 중앙집중식 환기 시스템을 위해 특별히 설계되었습니다.

◆ 휘발성 유기 화합물, 산성 및 알칼리성 가스, 포름 알데히드, 수은 증기, 방사성 가스와 같은 실제 요구에 따라 다양한 특수 활성탄 물질이 제공 될 수 있습니다.

Industrial Stainless Steel Filter Cartridges: Core Introduction

ONLY TECHNOLOGY’s industrial air filter lineup features stainless steel filter cartridge solutions that merge rugged durability with advanced purification capabilities, setting a new standard for industrial air treatment. These cartridges integrate the strength of stainless steel with the adsorption efficiency of an activated carbon air filter cartridge, creating a dual-performance system designed to thrive in the harshest industrial environments.

At their core, these stainless steel filter cartridge units are built for resilience. Constructed from 304 or 316 stainless steel—selected for superior corrosion resistance and temperature tolerance (up to 200°C)—they withstand exposure to chemicals, moisture, and mechanical stress that would degrade conventional filters. This robust casing protects the internal filtration media, ensuring consistent performance in factories, refineries, and manufacturing plants where dust, fumes, and corrosive gases are prevalent.

Complementing the stainless steel structure is an integrated activated carbon air filter cartridge component. This specialized media, engineered with high-porosity activated carbon (coconut shell or coal-based), targets gaseous contaminants such as VOCs, hydrogen sulfide, and industrial odors. The combination of physical adsorption (trapping molecules in carbon pores) and chemical reaction (neutralizing toxic gases) ensures comprehensive purification, addressing both particulate and gaseous pollutants in a single industrial air filter solution.

Unlike generic filters, these cartridges are designed for industrial-scale demands. Their cylindrical or pleated design maximizes filtration area, supporting high airflow rates (up to 2,000 m³/h) without excessive pressure drop—a critical feature for large ventilation systems. The stainless steel filter cartridge frame also allows for easy maintenance: the reusable shell can be opened to replace the activated carbon air filter cartridge media, reducing waste and lowering long-term costs.

As a versatile industrial air filter, they excel across diverse applications. In chemical processing, they remove solvent vapors and acid mists; in food production, they eliminate organic odors while meeting hygiene standards; in automotive plants, they capture paint fumes and oil aerosols. Their stainless steel construction ensures compliance with strict industry regulations, including FDA and ISO standards, making them suitable for sensitive environments.

Every stainless steel filter cartridge undergoes rigorous testing to verify structural integrity and filtration efficiency, ensuring it meets the demands of industrial operations. By combining the durability of stainless steel with the purification power of an activated carbon air filter cartridge, these units deliver not just filtration, but long-lasting, reliable air treatment—solidifying their role as a cornerstone of industrial air quality management.

Industrial Applications: Where SS & Activated Carbon Matter

In industrial environments, the synergy of stainless steel durability and activated carbon adsorption transforms the industrial air filter into an indispensable tool. ONLY TECHNOLOGY’s stainless steel filter cartridge paired with an activated carbon air filter cartridge excels in sectors where harsh conditions meet strict purification demands, proving their value in scenarios where generic filters fail.

Chemical Processing Plants rely on this combination to neutralize toxic fumes. Corrosive gases like chlorine and sulfur dioxide degrade standard filters, but the stainless steel filter cartridge’s 316 SS construction resists chemical erosion, while the activated carbon air filter cartridge adsorbs and neutralizes these gases. This dual protection ensures worker safety and compliance with environmental regulations, even in continuous operation.

Food & Beverage Production demands both purity and hygiene. The stainless steel filter cartridge’s smooth, non-porous surface prevents bacterial growth and withstands frequent sanitization (high-temperature washes, chemical cleaners), critical for meeting FDA standards. Meanwhile, the activated carbon air filter cartridge eliminates odors from fermentation, cooking, and packaging—ensuring product integrity and a pleasant workspace.

Automotive & Aerospace Facilities face mixed contaminants: paint booths emit VOCs and overspray, while machining areas generate metal dust. The industrial air filter addresses both: the activated carbon air filter cartridge traps solvent vapors (e.g., isocyanates), and the stainless steel filter cartridge’s robust frame handles high airflow and abrasive particles, reducing equipment wear and maintaining paint quality.

Wastewater Treatment Plants battle hydrogen sulfide (rotten-egg odor) and ammonia. Moisture and corrosive gases quickly degrade plastic filters, but the stainless steel filter cartridge’s corrosion resistance ensures longevity. The activated carbon air filter cartridge adsorbs these noxious gases, improving working conditions and preventing complaints from the surrounding communities.

Pharmaceutical Manufacturing requires sterile, contaminant-free air. The stainless steel filter cartridge resists corrosion from sanitizing agents, while the activated carbon air filter cartridge removes volatile solvents used in drug synthesis. This combination meets ISO 8 cleanroom standards, critical for preventing product contamination.

Energy & Power Plants (oil refineries, biomass facilities) face high temperatures and heavy hydrocarbons. The stainless steel filter cartridge withstands 200°C+ environments, and the activated carbon air filter cartridge captures methane, benzene, and fuel vapors—reducing fire risks and ensuring regulatory compliance.

In every application, the industrial air filter’s design ensures the stainless steel filter cartridge and activated carbon air filter cartridge work in harmony: durability handles the environment, and adsorption handles the contaminants. For industries where failure is not an option, this pairing delivers reliable, long-term performance.

메시지를 남겨주세요

이메일:

이메일: