Tel:

+8618931101301

Tel:

+8618931101301

דצמ . 04, 2024 19:07 Back to list

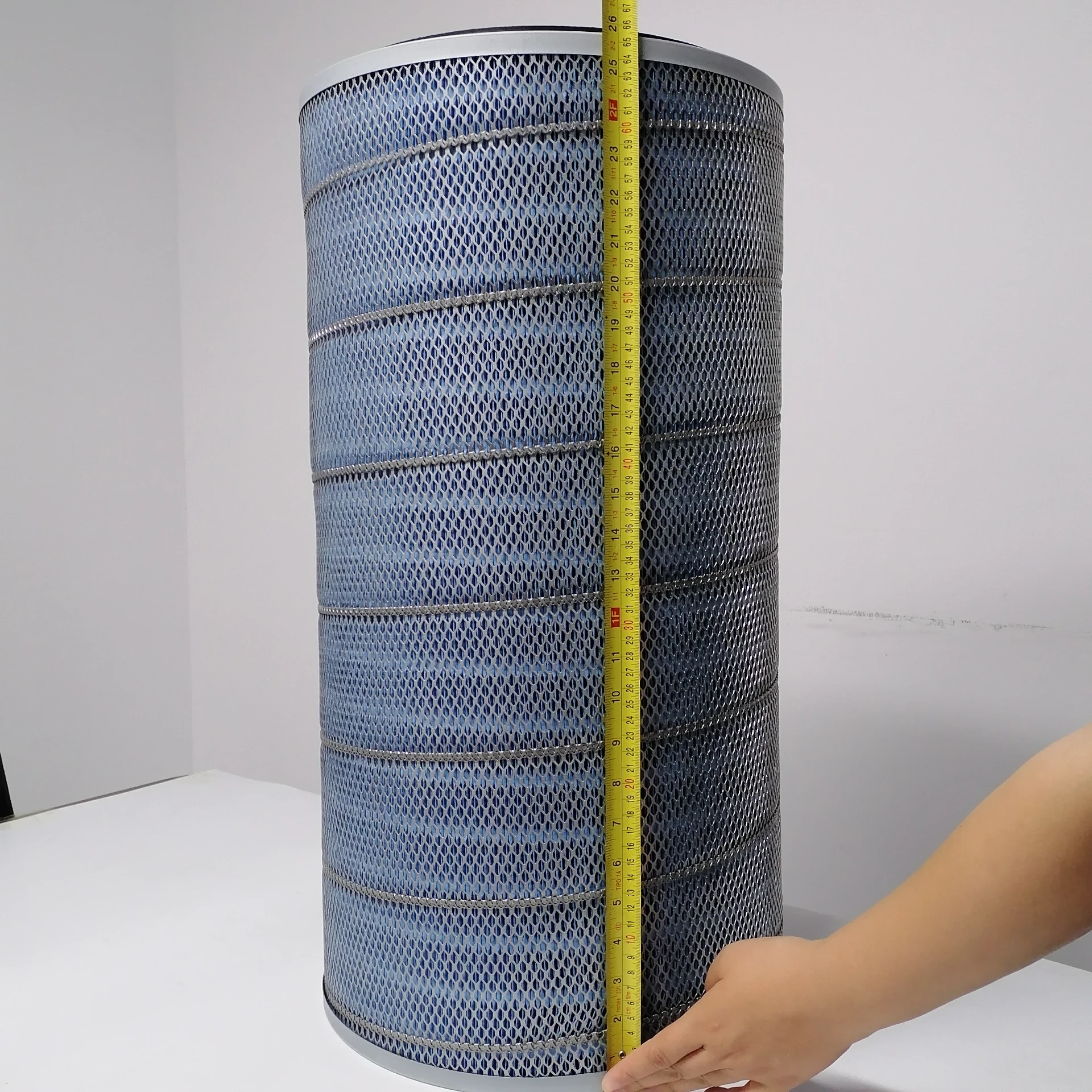

vacuum filter cartridge

Understanding Vacuum Filter Cartridges A Comprehensive Overview

In today's industrial and environmental landscape, the importance of efficient filtration cannot be overstated. Vacuum filter cartridges play a crucial role in various applications, including water treatment, food and beverage processing, and chemical manufacturing. This article explores the functionality, applications, and advantages of vacuum filter cartridges, shedding light on why they are a vital component in many filtering systems.

What is a Vacuum Filter Cartridge?

A vacuum filter cartridge is a cylindrical device designed to remove contaminants from liquids and gases using a vacuum filtration process. The basic principle behind this technology involves the application of negative pressure, which draws the fluid through a porous medium or filter material. This medium traps solid particles, allowing only the purified liquid to pass through. The efficiency of a vacuum filter cartridge largely depends on its design, construction materials, and the type of filtration media used.

How Does it Work?

The operation of a vacuum filter cartridge begins with the establishment of a vacuum pressure within the system. Typically, a vacuum pump creates this negative pressure, which pulls the liquid to be filtered into the cartridge. As the fluid enters, it passes through a filter element, which could be made from various materials such as stainless steel mesh, polypropylene, or activated carbon, depending on the specific application demands.

When the fluid flows through the filter, particles larger than the filter's pore size are trapped, while the clean liquid moves to the outlet side. This continuous flow is maintained as the vacuum creates a driving force, allowing for effective separation of solids from liquids. The filtered liquid can then be collected, treated, or reused, depending on the industry requirements.

Applications of Vacuum Filter Cartridges

vacuum filter cartridge

Vacuum filter cartridges have a wide range of applications across different sectors. In the water treatment industry, they are often used to purify municipal water supplies by removing sediments, bacteria, algae, and other pollutants. Additionally, in the food and beverage industry, these filters ensure that the final products meet stringent health and safety standards by removing contaminants that may impact taste or quality.

Moreover, vacuum filter cartridges are extensively utilized in chemical manufacturing for the filtration of solvents and other chemicals, ensuring that the processes remain contamination-free and efficient. In pharmaceuticals, these cartridges help maintain the purity of products by filtering out unwanted particulate matter and microorganisms.

Advantages of Vacuum Filter Cartridges

One of the primary advantages of vacuum filter cartridges is their efficiency. The vacuum-assisted filtration process allows for faster filtration rates compared to traditional gravity-based filters. This efficiency translates to reduced operational costs and increased throughput, making them ideal for high-demand applications.

Additionally, vacuum filter cartridges are versatile and can be designed to accommodate various flow rates, pressures, and filtration requirements. This adaptability ensures they can meet the specific needs of diverse industrial processes. Furthermore, they require minimal maintenance, with many designs featuring replaceable filter elements that can be effortlessly swapped out when needed.

Conclusion

In summary, vacuum filter cartridges are indispensable tools in modern filtration systems. Their functionality, adaptability, and efficiency make them suitable for a broad spectrum of applications across various industries. By understanding their operation and advantages, industries can optimize their filtration processes, enhance product quality, and comply with environmental regulations. As technology advances, we can expect further innovations in vacuum filtration, ensuring cleaner, safer, and more sustainable practices for years to come.

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

-

Air filter survival guide in high-dust environmentsNewsApr.23,2025

-

How do air filters cope with high-concentration dust environments?NewsApr.21,2025

Email:

Email: