Tel:

+8615930870079

Tel:

+8615930870079

אוג . 18, 2024 02:18 Back to list

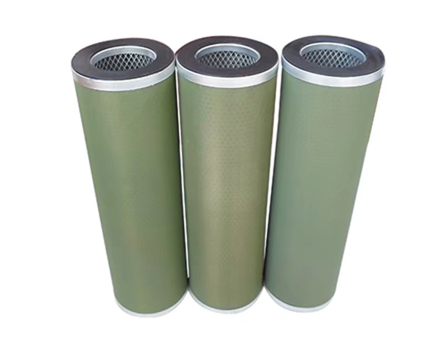

Vacuum Cartridge Filters for Efficient Filtration and Dust Collection Systems

Understanding Cartridge Filter Vacuum Systems

Cartridge filter vacuum systems have emerged as essential tools in various industrial and commercial applications, providing efficient solutions for managing particulate and liquid contaminants. Known for their effectiveness in filtering processes, these systems are designed to enhance production quality and ensure compliance with environmental regulations.

What is a Cartridge Filter?

A cartridge filter is a type of filter element that captures particles from fluids or air as they pass through the filter. Unlike traditional filtration systems, cartridge filters come in a cylindrical shape that allows for a larger surface area and, consequently, greater filtration capacity. They are typically made from various materials such as cellulose, synthetic fibers, or membranes, depending on the application requirements.

How Does Vacuum Funktion with Cartridge Filters?

In vacuum systems, cartridge filters play a crucial role in separating solids from liquids or gases. When a vacuum is created, it generates a pressure differential that draws fluid through the filter media. This process effectively prevents larger particles from passing through while allowing the treated fluid to exit cleanly. The integration of cartridge filters in vacuum systems leads to improved efficiency and longevity of the overall setup by reducing wear and tear on pumps and other internal components.

Applications of Cartridge Filter Vacuum Systems

Cartridge filter vacuum systems are widely used across various industries, including food and beverage, pharmaceuticals, chemical manufacturing, and automotive. In food and beverage, these systems ensure that products are free from impurities, which is critical for maintaining hygiene and safety standards. In the pharmaceutical industry, accurate filtration is vital to prevent contamination and ensure product efficacy.

cartridge filter vacuum

Another significant application is in the chemical manufacturing sector, where cartridge filter vacuum systems are employed to handle corrosive or hazardous materials. These systems provide an effective way to maintain a clean working environment while protecting workers from harmful substances. Additionally, in the automotive industry, these filters are used to capture debris and ensure that manufacturing processes run smoothly, reducing downtime and increasing productivity.

Advantages of Using Cartridge Filter Vacuum Systems

1. High Efficiency Cartridge filters offer superior filtration performance, capturing a wide range of particulate sizes. Their design facilitates optimal flow rate while maximizing filtration efficiency.

2. Cost-Effective While the initial investment in a cartridge filter vacuum system might be substantial, the long-term savings from reduced downtime, lower maintenance costs, and enhanced product quality make it a wise choice for many industries.

3. Versatility These systems can be tailored to fit various applications, demonstrating flexibility in handling different fluid types and contaminant loads. This adaptability ensures that businesses can optimize their operations according to specific needs.

4. Sustainability The ability to maintain cleanliness and efficiency in production processes contributes to reduced waste and improved sustainability outcomes. Cartridge filters can often be cleaned and reused, further minimizing environmental impact.

Conclusion

Cartridge filter vacuum systems represent a pivotal development in the realm of filtration technology, offering a practical and efficient approach to managing contaminants in various industrial settings. As industries continue to evolve, the importance of reliable and effective filtration will only grow, solidifying the role of cartridge filters as an integral component of modern chemical and manufacturing processes. By investing in these systems, companies can enhance their operational efficiency, comply with regulatory requirements, and ultimately deliver higher quality products to their customers.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: