Tel:

+8618931101301

Tel:

+8618931101301

נוב . 17, 2024 21:27 Back to list

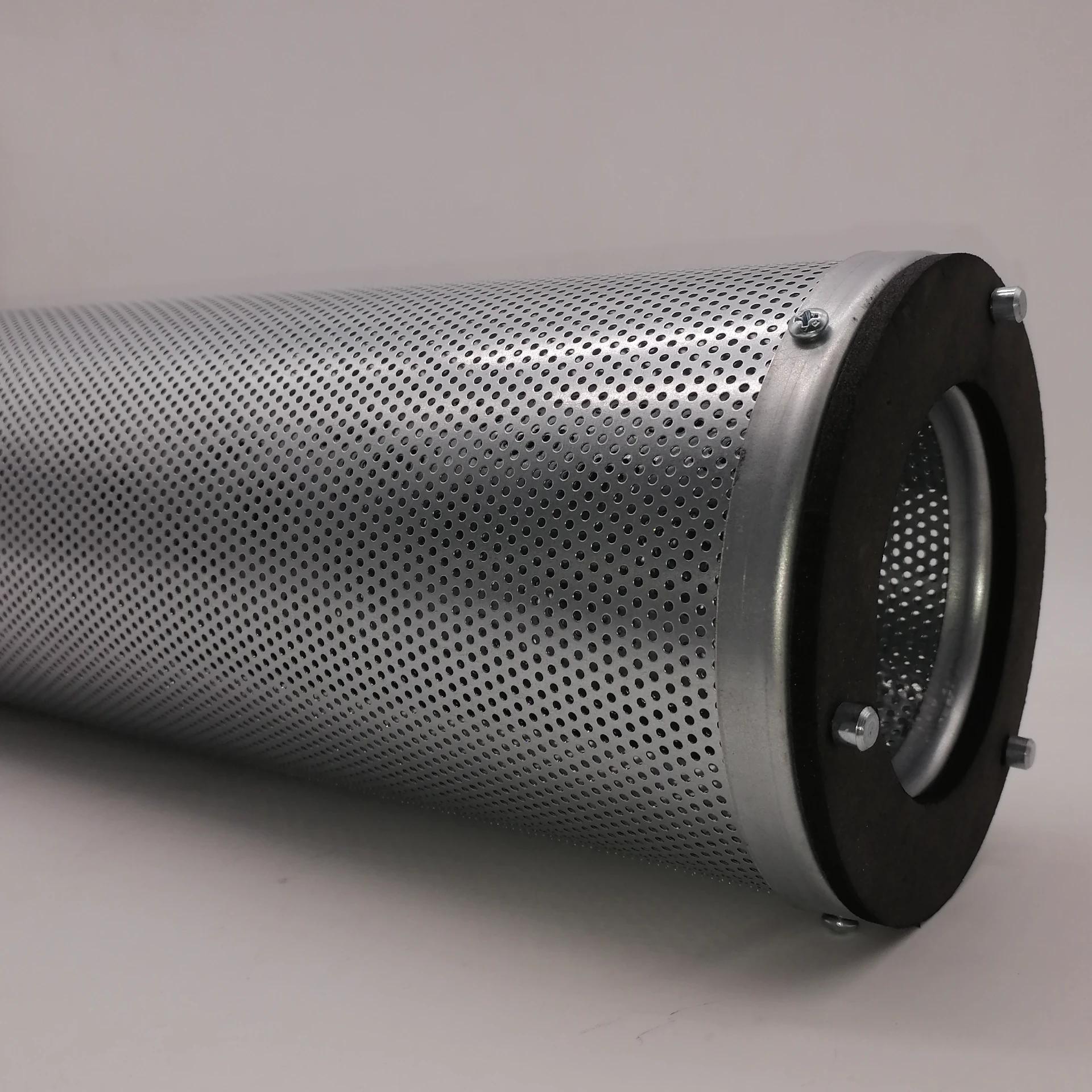

stainless steel mesh filter cartridge

The Versatility and Importance of Stainless Steel Mesh Filter Cartridges

Stainless steel mesh filter cartridges are an essential component in numerous filtration applications across various industries. Their durable design, resistance to corrosion, and ability to withstand high temperatures make them a preferred choice for many industrial processes. In this article, we will explore the functionalities, advantages, and applications of stainless steel mesh filter cartridges.

What Are Stainless Steel Mesh Filter Cartridges?

Stainless steel mesh filter cartridges are cylindrical filtration devices made from woven stainless steel mesh. The mesh is designed with varying pore sizes, allowing for the effective separation of solid particles from fluids such as water, oil, and chemicals. These cartridges can be easily installed in different filtration systems and are often used in conjunction with other filtration media to achieve higher efficiency.

Key Advantages

1. Durability One of the most significant benefits of stainless steel mesh filter cartridges is their durability. Unlike plastic or paper filters that can deteriorate over time, stainless steel is resistant to wear and tear. This longevity translates to reduced replacement costs and less downtime in industrial operations.

2. Corrosion Resistance Stainless steel's inherent resistance to corrosion makes it ideal for filtering corrosive fluids. Industries such as oil and gas, chemical processing, and wastewater treatment frequently face challenges when dealing with aggressive chemicals. Stainless steel mesh filters can endure these harsh environments, ensuring reliable performance.

3. High-Temperature Tolerance Many industrial processes involve the use of high-temperature fluids. Stainless steel mesh filter cartridges can operate effectively in temperatures exceeding 500°F (260°C), making them suitable for applications like steam, hot oil, and chemical processes.

4. Customizability Stainless steel mesh filters can be manufactured in various shapes, sizes, and mesh configurations, allowing them to be tailored to specific filtration needs. This customization ensures optimal performance, regardless of the application.

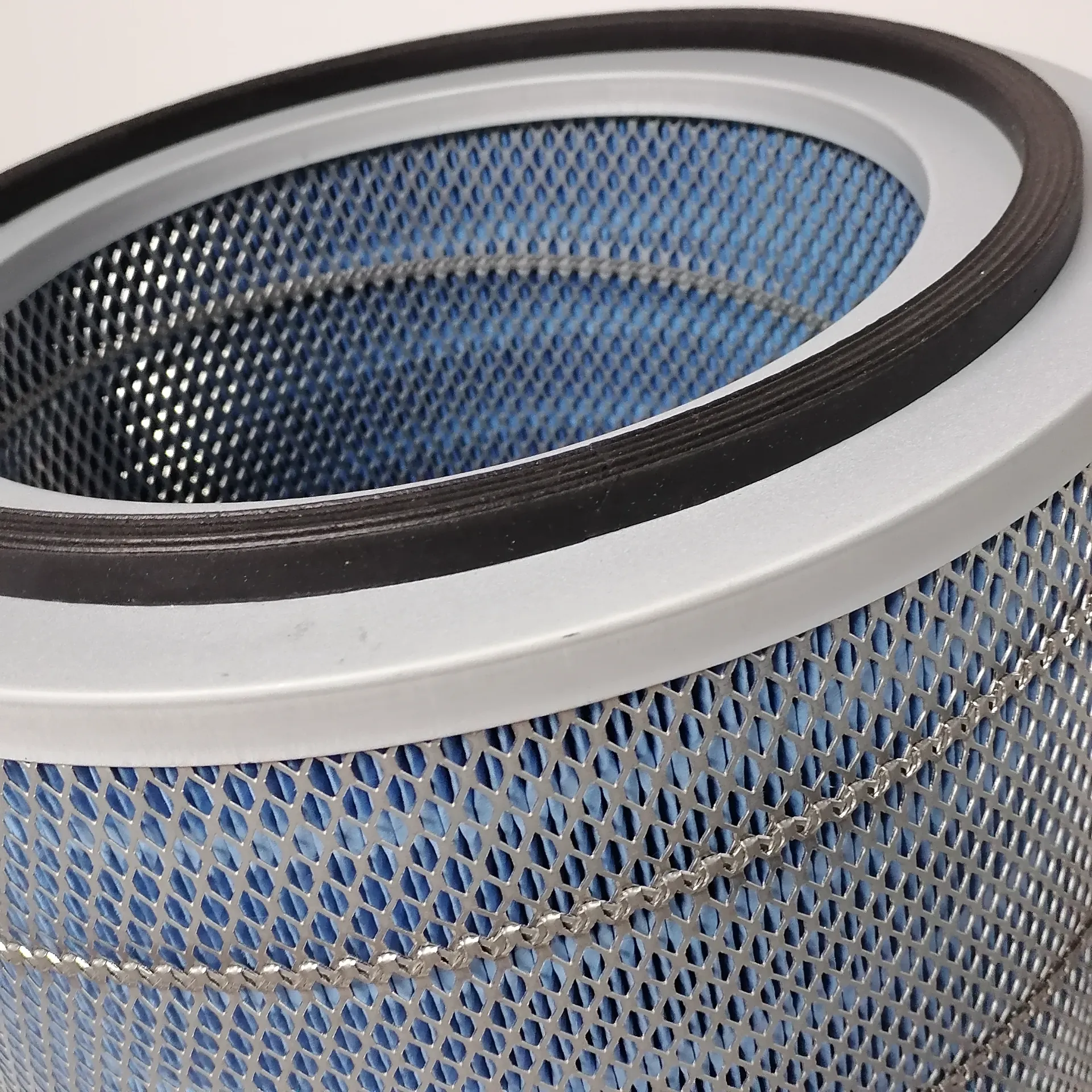

stainless steel mesh filter cartridge

5. Easy Cleaning and Maintenance Unlike disposable filters, stainless steel mesh cartridges can be cleaned and reused. This feature not only reduces waste but also minimizes the frequency of replacements needed, leading to lower operational costs.

Applications

Stainless steel mesh filter cartridges have a wide array of applications across different sectors

- Food and Beverage Industry They are used to filter liquids in food processing, ensuring product purity and compliance with health regulations. - Pharmaceuticals In the pharmaceutical industry, these cartridges filter critical fluids to maintain sterile conditions during the production process. - Oil and Gas They are employed in extraction and refining processes, filtering out impurities from crude oil and natural gas.

- Water Treatment Municipalities and industries utilize these filters to remove sediments and contaminants from water, ensuring the supply of clean and safe drinking water.

- Chemical Processing In chemical plants, stainless steel filters can help manage by-products and solid particles generated during reactions.

Conclusion

In summary, stainless steel mesh filter cartridges play a vital role in ensuring the efficient and safe operation of various industrial processes. Their durability, resistance to corrosion, high-temperature tolerance, and ease of maintenance make them an invaluable tool for industries that require reliable filtration solutions. As technology advances and industries continue to evolve, the importance of effective filtration methods like stainless steel mesh filter cartridges will only grow, driving innovation and efficiency in manufacturing and processing operations across the globe. Whether in food and beverage production or complex chemical processes, these filters are essential in maintaining quality and safety standards, solidifying their place in today's industrial landscape.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: