ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

פבר . 15, 2025 15:06 Back to list

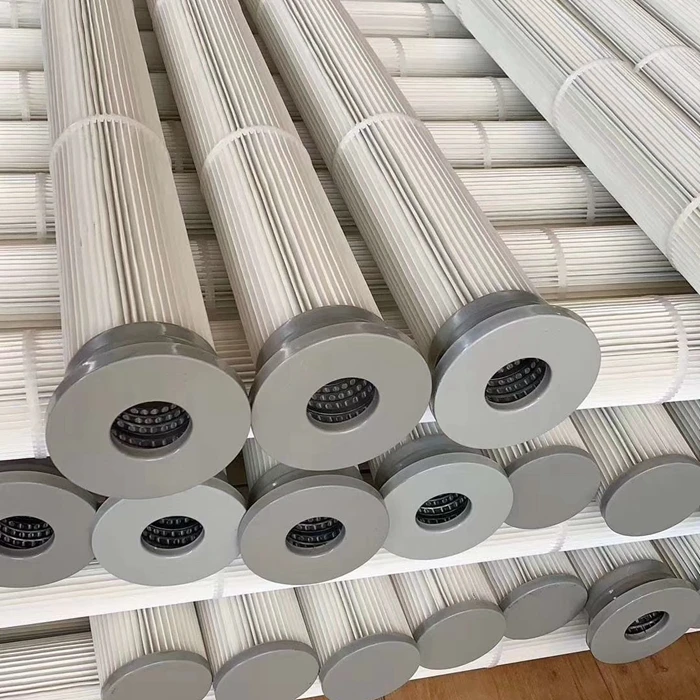

sintered metal filter cartridge

In the rapidly evolving field of filtration technology, the sintered metal filter cartridge stands out as a revolutionary element, providing solutions that cater to diverse applications across industries. Combining outstanding performance with longevity, these cartridges are essential for processes that demand high levels of purification, especially in challenging environments.

In the realm of pharmaceuticals, sintered metal filter cartridges have revolutionized filtration systems by providing unparalleled sterility and particulate-free environments, essential for the safe production of medicines. The ability to withstand repeated cleaning and sterilization processes without degradation in performance underscores their value in ensuring product safety and efficacy. Their application extends to the food and beverage industry as well, where maintaining product purity is not just a regulatory requirement but also a customer expectation. Sintered metal filters ensure that beverages are free from bacterial contamination and particulate, enhancing the taste and safety of the final product. Trust plays a significant role in the adoption of any filtration technology, and sintered metal filters have earned their reputation through rigorous testing and adherence to international standards. Manufacturers ensure that each cartridge undergoes stringent quality control processes to guarantee their reliability and performance under the most demanding conditions. Apart from industrial applications, the versatility of sintered metal filter cartridges has found them a place in residential and commercial settings where clean water and air are vital. Their compact yet efficient design makes them suitable for use in HVAC systems and water purification systems, delivering a high standard of living through improved air and water quality. In conclusion, sintered metal filter cartridges represent a pinnacle of filtration technology—a culmination of durability, versatility, and efficiency. Their proven track record across various industries speaks volumes of their reliability and effectiveness. For businesses looking to enhance productivity while maintaining stringent quality and safety standards, investing in sintered metal filter cartridges is not just an option; it’s a necessity. Their ability to adapt to specific filtration needs without compromising performance assures stakeholders of their value in any setting, underscoring the cardinal principles of experience, expertise, authoritativeness, and trustworthiness.

In the realm of pharmaceuticals, sintered metal filter cartridges have revolutionized filtration systems by providing unparalleled sterility and particulate-free environments, essential for the safe production of medicines. The ability to withstand repeated cleaning and sterilization processes without degradation in performance underscores their value in ensuring product safety and efficacy. Their application extends to the food and beverage industry as well, where maintaining product purity is not just a regulatory requirement but also a customer expectation. Sintered metal filters ensure that beverages are free from bacterial contamination and particulate, enhancing the taste and safety of the final product. Trust plays a significant role in the adoption of any filtration technology, and sintered metal filters have earned their reputation through rigorous testing and adherence to international standards. Manufacturers ensure that each cartridge undergoes stringent quality control processes to guarantee their reliability and performance under the most demanding conditions. Apart from industrial applications, the versatility of sintered metal filter cartridges has found them a place in residential and commercial settings where clean water and air are vital. Their compact yet efficient design makes them suitable for use in HVAC systems and water purification systems, delivering a high standard of living through improved air and water quality. In conclusion, sintered metal filter cartridges represent a pinnacle of filtration technology—a culmination of durability, versatility, and efficiency. Their proven track record across various industries speaks volumes of their reliability and effectiveness. For businesses looking to enhance productivity while maintaining stringent quality and safety standards, investing in sintered metal filter cartridges is not just an option; it’s a necessity. Their ability to adapt to specific filtration needs without compromising performance assures stakeholders of their value in any setting, underscoring the cardinal principles of experience, expertise, authoritativeness, and trustworthiness.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: