Tel:

+8618931101301

Tel:

+8618931101301

נוב . 10, 2024 16:45 Back to list

Silo Filter Cartridge Solutions for Enhanced Filtration and Performance Efficiency

Understanding Silo Filter Cartridges Key Components for Industrial Filtration

In the realm of industrial filtration, silo filter cartridges are essential components that play a pivotal role in ensuring clean air and efficient operations. These cartridges are specifically designed to capture and filter out dust and particulate matter from gases in various industrial settings, particularly in bulk storage and processing facilities. This article will delve into the structure, functionality, and benefits of silo filter cartridges, while also highlighting their importance in maintaining a safe and efficient work environment.

What is a Silo Filter Cartridge?

A silo filter cartridge is a specialized filtration element used in dust collection systems, particularly those associated with silos that store bulk materials such as grain, cement, chemical powders, and more. The primary function of these cartridges is to remove particulate matter from the air that is displaced during the loading and unloading of materials. By doing so, they help maintain air quality, protect equipment from damage, and ensure compliance with environmental regulations.

Design and Composition

Silo filter cartridges are typically made from high-performance filter media, which can vary according to the specific application and material being handled. Common materials include polyester, polypropylene, and Teflon, which offer varying degrees of filtration efficiency, chemical resistance, and temperature tolerance. The design of these cartridges is crucial; they often feature a pleated structure that increases the surface area available for filtration, allowing for efficient dust collection while minimizing airflow resistance.

Most silo filter cartridges are cylindrical and are installed in a dust collector system. This system utilizes negative pressure to draw air through the filter. As air passes through the filter media, solid particles are captured on the surface side while clean air is released on the opposite side. This process can be further enhanced through pulse jet cleaning systems, which periodically blast compressed air through the cartridges to dislodge accumulated dust and maintain optimal performance.

Benefits of Silo Filter Cartridges

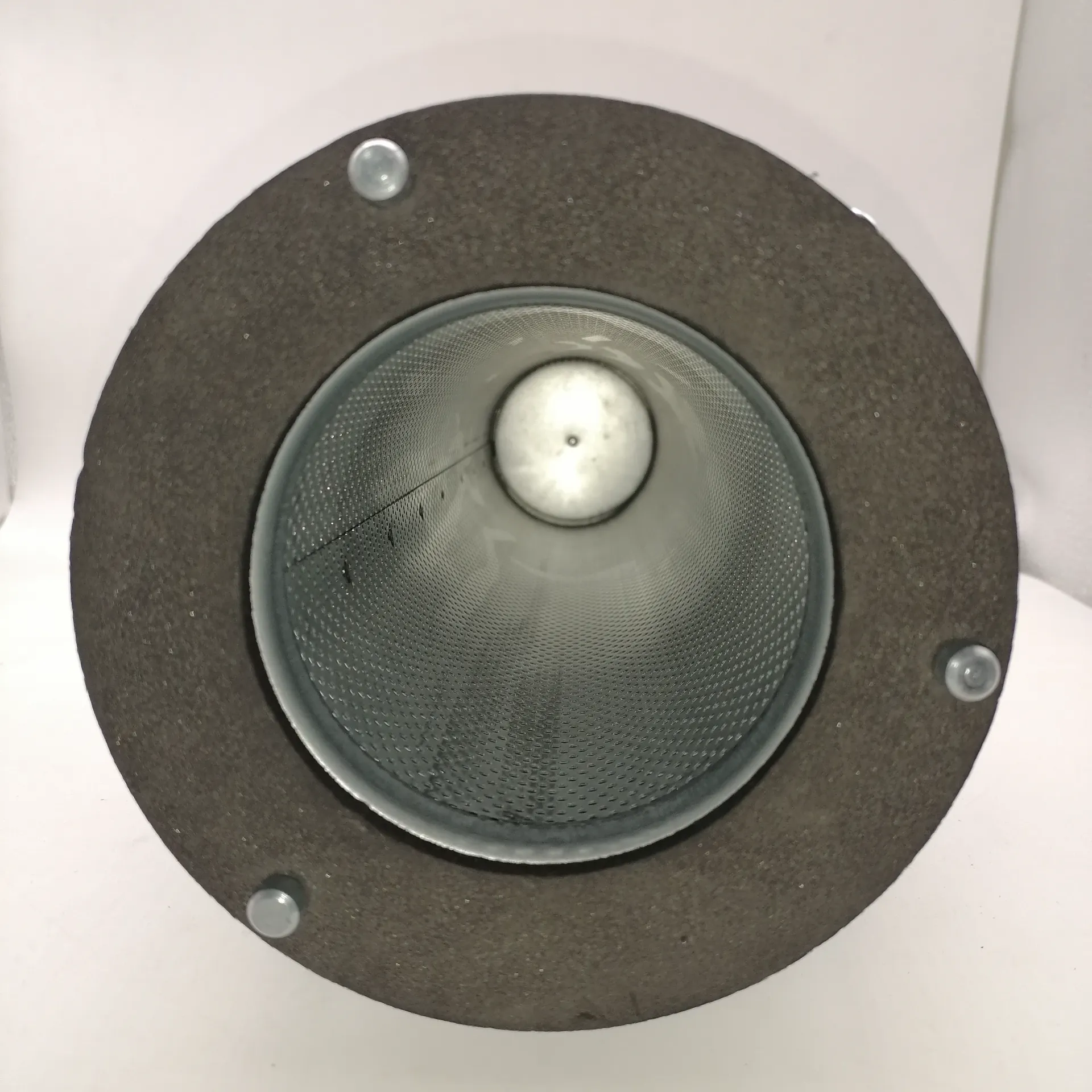

silo filter cartridge

1. Improved Air Quality By effectively filtering out dust and particulate matter, silo filter cartridges help to ensure that the air in and around industrial facilities remains clean and safe for workers. This is especially important in environments where fine particulates can pose health risks.

2. Regulatory Compliance Many industries are subject to strict environmental regulations regarding air quality. Utilizing high-quality silo filter cartridges helps organizations comply with these regulations, avoiding potential fines and legal issues.

3. Equipment Protection Dust accumulation can cause significant wear and tear on machinery, leading to increased maintenance costs and unplanned downtimes. By capturing dust at the source, silo filter cartridges can extend the lifespan of equipment and ensure smoother operations.

4. Enhanced Efficiency Clean air and effective dust control translate into more efficient industrial processes. Businesses can achieve higher production rates and reduce operational disruptions caused by dust accumulation.

5. Cost-Effectiveness While the initial investment in high-quality silo filter cartridges may be higher than lower-quality alternatives, the long-term savings associated with reduced maintenance, improved efficiency, and compliance can far outweigh the costs.

Conclusion

Silo filter cartridges are vital to industrial filtration systems, providing effective dust control, improving air quality, and ensuring regulatory compliance. Their advanced design and high-performance filtration media ensure that they can handle the demands of various industrial applications. As industries continue to prioritize health, safety, and efficiency, the role of silo filter cartridges will only become more prominent, making them a key component in the operations of bulk storage facilities worldwide. Investing in quality filtration solutions is not just a regulatory necessity but a strategic business decision that contributes to the overall sustainability and profitability of industrial operations.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: