ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

יונ . 25, 2024 04:48 Back to list

High Efficiency Gas Turbine Filter Optimization for Enhanced Performance and Reliability

The Role and Significance of Gas Turbine Filters in Power Generation

In the realm of modern power generation, gas turbines play a pivotal role in meeting the world's ever-increasing energy demands. At the heart of these high-speed machines lies a critical component that ensures efficient and clean operation - the gas turbine filter. This article delves into the importance, function, and advancements in gas turbine filters.

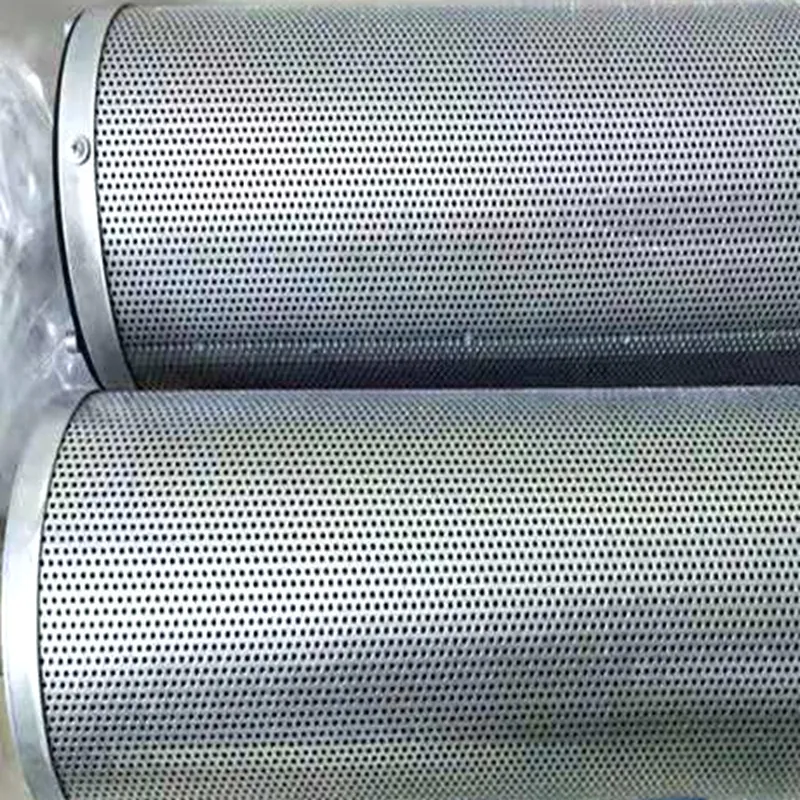

A gas turbine filter, often referred to as a centrifugal or cartridge filter, is designed specifically for removing impurities from the incoming fuel or air stream before it enters the combustion chamber. These impurities, ranging from dust particles, water droplets, and even small metal fragments, can severely hamper the performance and longevity of the engine if left unchecked.

The primary function of a gas turbine filter is to maintain the purity of the airflow, which directly impacts the combustion process. Clean air allows for more effective fuel-air mixing, resulting in higher combustion efficiency and lower emissions. Moreover, it safeguards the delicate components within the turbine, preventing wear and tear due to foreign particles, thus extending the overall system lifespan.

Advancements in gas turbine filter technology have been significant over the years. Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures

Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures gas turbine filter. Some filters now employ advanced filtration media like labyrinth seals, which offer better sealing and longer operational intervals without maintenance.

Moreover, electronic filters equipped with monitoring systems can detect even minute changes in filtration efficiency, allowing for proactive maintenance rather than relying solely on scheduled replacements. This not only saves operational costs but also minimizes downtime, crucial in the fast-paced world of power generation.

Furthermore, research is ongoing to develop filters that can adapt to varying operating conditions, such as changing ambient temperatures or varying levels of contamination. These smart filters can self-cleaning or adjust their efficiency based on real-time data, ensuring optimal performance under any circumstances.

In conclusion, the gas turbine filter is a vital cog in the machinery of modern power generation. Its effectiveness directly contributes to the reliability, efficiency, and sustainability of gas turbine operations. As technology continues to evolve, so do the capabilities of these filters, making them an indispensable part of the quest for cleaner, more efficient energy production.

gas turbine filter. Some filters now employ advanced filtration media like labyrinth seals, which offer better sealing and longer operational intervals without maintenance.

Moreover, electronic filters equipped with monitoring systems can detect even minute changes in filtration efficiency, allowing for proactive maintenance rather than relying solely on scheduled replacements. This not only saves operational costs but also minimizes downtime, crucial in the fast-paced world of power generation.

Furthermore, research is ongoing to develop filters that can adapt to varying operating conditions, such as changing ambient temperatures or varying levels of contamination. These smart filters can self-cleaning or adjust their efficiency based on real-time data, ensuring optimal performance under any circumstances.

In conclusion, the gas turbine filter is a vital cog in the machinery of modern power generation. Its effectiveness directly contributes to the reliability, efficiency, and sustainability of gas turbine operations. As technology continues to evolve, so do the capabilities of these filters, making them an indispensable part of the quest for cleaner, more efficient energy production.

Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures

Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures Traditional filters were typically made of or metallic elements, but modern designs incorporate composite materials, providing improved durability and resistance to high temperatures gas turbine filter. Some filters now employ advanced filtration media like labyrinth seals, which offer better sealing and longer operational intervals without maintenance.

Moreover, electronic filters equipped with monitoring systems can detect even minute changes in filtration efficiency, allowing for proactive maintenance rather than relying solely on scheduled replacements. This not only saves operational costs but also minimizes downtime, crucial in the fast-paced world of power generation.

Furthermore, research is ongoing to develop filters that can adapt to varying operating conditions, such as changing ambient temperatures or varying levels of contamination. These smart filters can self-cleaning or adjust their efficiency based on real-time data, ensuring optimal performance under any circumstances.

In conclusion, the gas turbine filter is a vital cog in the machinery of modern power generation. Its effectiveness directly contributes to the reliability, efficiency, and sustainability of gas turbine operations. As technology continues to evolve, so do the capabilities of these filters, making them an indispensable part of the quest for cleaner, more efficient energy production.

gas turbine filter. Some filters now employ advanced filtration media like labyrinth seals, which offer better sealing and longer operational intervals without maintenance.

Moreover, electronic filters equipped with monitoring systems can detect even minute changes in filtration efficiency, allowing for proactive maintenance rather than relying solely on scheduled replacements. This not only saves operational costs but also minimizes downtime, crucial in the fast-paced world of power generation.

Furthermore, research is ongoing to develop filters that can adapt to varying operating conditions, such as changing ambient temperatures or varying levels of contamination. These smart filters can self-cleaning or adjust their efficiency based on real-time data, ensuring optimal performance under any circumstances.

In conclusion, the gas turbine filter is a vital cog in the machinery of modern power generation. Its effectiveness directly contributes to the reliability, efficiency, and sustainability of gas turbine operations. As technology continues to evolve, so do the capabilities of these filters, making them an indispensable part of the quest for cleaner, more efficient energy production. Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: