Tel:

+8615930870079

Tel:

+8615930870079

דצמ . 05, 2024 15:23 Back to list

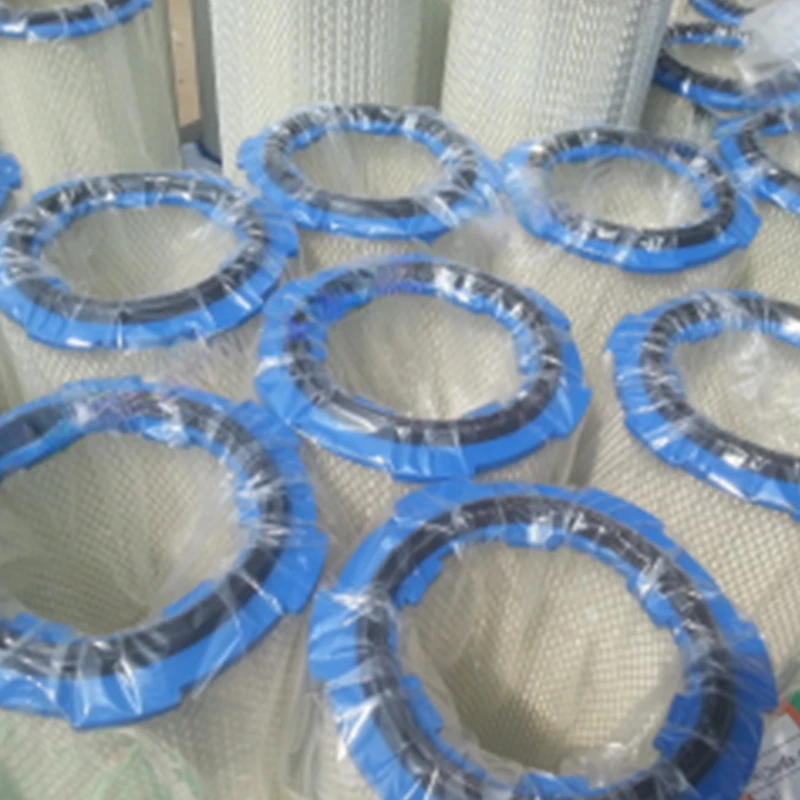

gas turbine air intake filter manufacturers

Overview of Gas Turbine Air Intake Filter Manufacturers

Gas turbines are critical components in many industries, including energy generation, aviation, and industrial applications. Their efficiency and performance are heavily influenced by the quality of the air intake filters used. These filters play a pivotal role in protecting the turbine from contaminants in the air, including dust, dirt, and other particulates. As a result, gas turbine air intake filter manufacturers are essential players in ensuring the longevity and performance of gas turbines.

Importance of Air Intake Filters

The air-fuel mixture in a gas turbine must be as clean as possible for optimal combustion and efficiency. Air intake filters serve to minimize the entry of harmful substances that can cause erosion, corrosive damage, or other mechanical issues within the turbine. High-quality air intake filters contribute to

1. Enhanced Performance Clean air leads to better combustion efficiency, which translates into higher power output and lower operational costs. 2. Extended Equipment Life By safeguarding the turbine from abrasive particles, filters help extend the lifespan of turbine components, thereby reducing replacement and maintenance costs. 3. Lower Emissions Efficient air filtration leads to improved combustion, which can significantly lower emissions and enhance compliance with environmental regulations.

Types of Filters

Gas turbine air intake filters come in various types, tailored to meet the specific requirements of different applications. The most common types include

1. Panel Filters These are flat filters that provide a large surface area for capturing particles. They are often used in hoods and air handling units. 2. Pleated Filters With a design that maximizes surface area, pleated filters are capable of trapping more dust and extending service life. They are widely used in industrial applications where high levels of contaminants are expected.

3. Bag Filters These filters are designed to hold a significant amount of dust and are particularly effective in environments with heavy particulate loads. They are often employed in power plants and large industrial setups.

4. Cyclone Filters These utilize centrifugal force to separate larger particles from the air stream before they reach the main filter, thereby improving filter longevity and efficiency.

5. HEPA Filters High-Efficiency Particulate Air filters are capable of trapping at least 99.97% of particles that are 0.3 microns in size, making them ideal for applications that require exceptionally clean air.

Choosing the Right Manufacturer

When selecting a manufacturer for gas turbine air intake filters, several factors should be considered

gas turbine air intake filter manufacturers

1. Quality Standards Look for manufacturers that adhere to international quality standards and have certifications such as ISO 9001. This ensures that the products meet reliability and performance benchmarks.

2. Experience and Expertise Companies with extensive experience in the gas turbine industry will have a better understanding of specific requirements and challenges related to air intake filtration.

3. Technological Innovation Manufacturers that invest in research and development are more likely to offer advanced filters using the latest materials and designs, resulting in better performance and efficiency.

4. Customer Support Reliable customer service and technical support can be crucial, especially when dealing with complex filtration systems. A manufacturer that provides ongoing support can help you maintain optimal performance over time.

5. Customization Options Every application is unique, and the ability to customize filters based on specific operational needs can greatly enhance performance and efficiency.

Leading Manufacturers in the Market

While many manufacturers produce air intake filters for gas turbines, some of the industry leaders include

- Parker Hannifin Known for its advanced filtration solutions, Parker Hannifin provides a wide range of air intake filters specifically designed for gas turbines.

- AAF International AAF offers high-performance air filtration products and has extensive experience in the energy sector, ensuring reliable and efficient filters.

- Donaldson Company, Inc. With a strong reputation in the filtration industry, Donaldson manufactures a variety of filters suitable for different gas turbine applications.

- Camfil Camfil specializes in clean air solutions and provides filters designed to maximize gas turbine performance while minimizing energy consumption.

Conclusion

The role of gas turbine air intake filter manufacturers is crucial in ensuring the efficiency, reliability, and longevity of gas turbines. By choosing high-quality filters from respected manufacturers, industries can optimize their gas turbine operations and contribute to a more sustainable future. As technology advances, the importance of effective air filtration will only increase, making the role of these manufacturers even more significant moving forward.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: