Tel:

+8618931101301

Tel:

+8618931101301

ספט . 22, 2024 16:13 Back to list

gas turbine air intake filter

Gas Turbine Air Intake Filters Importance and Functionality

Gas turbines are pivotal in various industries, including power generation, aviation, and marine applications. At the heart of these systems lies an often-overlooked component the air intake filter. The role of air intake filters is critical, as they ensure that the combustion process operates efficiently and effectively.

The primary function of air intake filters in gas turbines is to clean the incoming air before it enters the combustion chamber. Gas turbines require a large volume of air to mix with fuel and produce the high-pressure gas that drives the turbine blades. However, this incoming air can contain various contaminants, such as dust, dirt, pollen, and other particulate matter. If these impurities enter the system, they can adversely affect the performance of the turbine, leading to increased maintenance costs, reduced efficiency, and even potential failures.

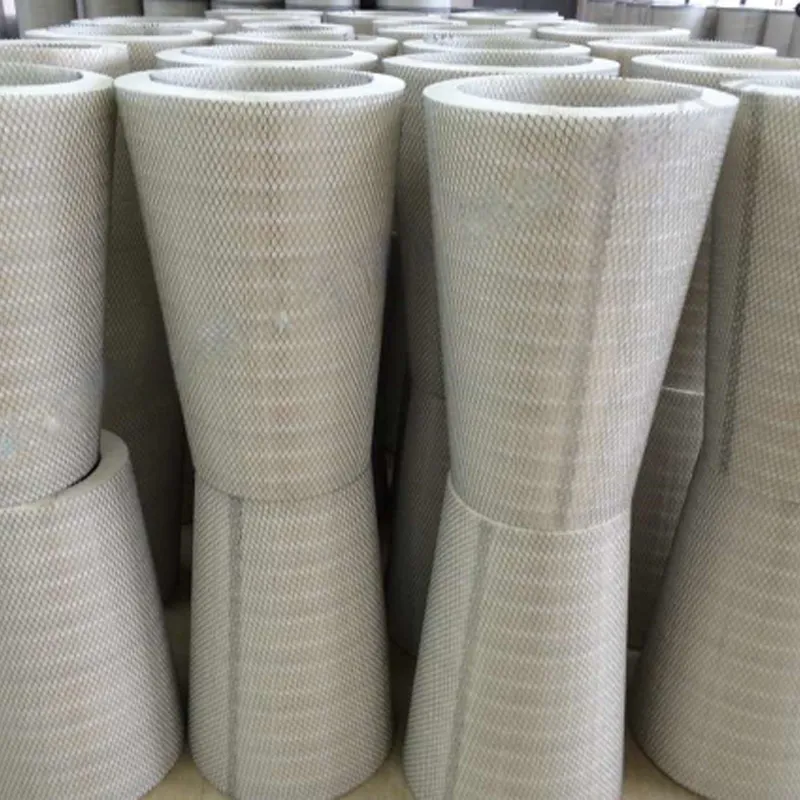

By using high-quality air intake filters, operators can significantly improve the lifespan and reliability of gas turbines. These filters are designed to trap and retain particles, ensuring that only clean air enters the combustion chamber. There are different types of filters employed, including mechanical filters, electrostatic filters, and chemical filters, each serving a unique purpose based on the specific operational environment and requirements of the turbine.

gas turbine air intake filter

Maintenance of air intake filters is essential to ensure optimal performance. Regularly inspecting and replacing filters can lead to improved airflow and, subsequently, greater efficiency. Clogged or dirty filters can restrict airflow, causing the turbine to work harder and consume more fuel, thereby negating any cost savings derived from efficient performance. Hence, adopting a regular maintenance schedule is crucial for any facility relying on gas turbines.

Moreover, the design of air intake systems can vary, depending on the application. Some systems utilize pre-filters to capture larger particles before the air reaches the main filter, enhancing the overall filtration process. Others may incorporate advanced technologies, such as humidity control or temperature regulation, to further improve air quality and performance.

In addition to enhancing efficiency, effective air intake filtration plays an important role in environmental compliance. Gas turbines that operate with clean air contribute to lower emissions, helping to meet stringent environmental regulations. This aspect is particularly vital in today’s eco-conscious world, where industries are increasingly held accountable for their environmental impact.

In conclusion, gas turbine air intake filters are a critical component that significantly influences the overall efficiency and longevity of gas turbines. By ensuring the cleanliness of the air entering the combustion chamber, these filters help enhance operational performance, reduce maintenance costs, and promote environmental sustainability. Investing in quality filters and maintaining them diligently is a practical approach for any organization relying on gas turbine technology.

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

Email:

Email: