Tel:

+8615930870079

Tel:

+8615930870079

דצמ . 31, 2024 06:49 Back to list

Improving Air Quality in Gas Turbine Systems with Advanced Intake Filters

The Importance of Air Intake Filters in Gas Turbines

Gas turbines are pivotal components in the energy and aerospace industries, renowned for their efficiency and power generation capabilities. However, their performance and longevity are heavily influenced by various factors, with air intake filters playing a crucial role. These filters are essential for ensuring optimal operation, protecting the turbine components, and enhancing overall efficiency.

Understanding Gas Turbine Operation

A gas turbine operates by drawing in air, compressing it, mixing it with fuel, and igniting the mixture to produce high-velocity exhaust gases that drive the turbine blades. The quality of the air entering the turbine is vital, as impurities can significantly impact its performance. This is where air intake filters come into play. They serve as the first line of defense, preventing dust, dirt, and other contaminants from entering the system.

Types of Air Intake Filters

Air intake filters for gas turbines can be broadly classified into two categories wet and dry filters. Wet filters typically use water or oil to trap particles, while dry filters rely on synthetic membranes or paper materials to capture contaminants. Each type has its advantages; for instance, wet filters can handle large volumes of particulate matter effectively, while dry filters are easier to maintain and replace.

The Role of Filters in Efficiency and Performance

The efficiency of a gas turbine is often directly linked to the quality of air intake. When unfiltered air filled with particulates enters the turbine, it can lead to premature wear and tear on the blades, reduced airflow, and decreased combustion efficiency. This inefficiency not only affects the power output but also leads to increased fuel consumption, leading to higher operational costs.

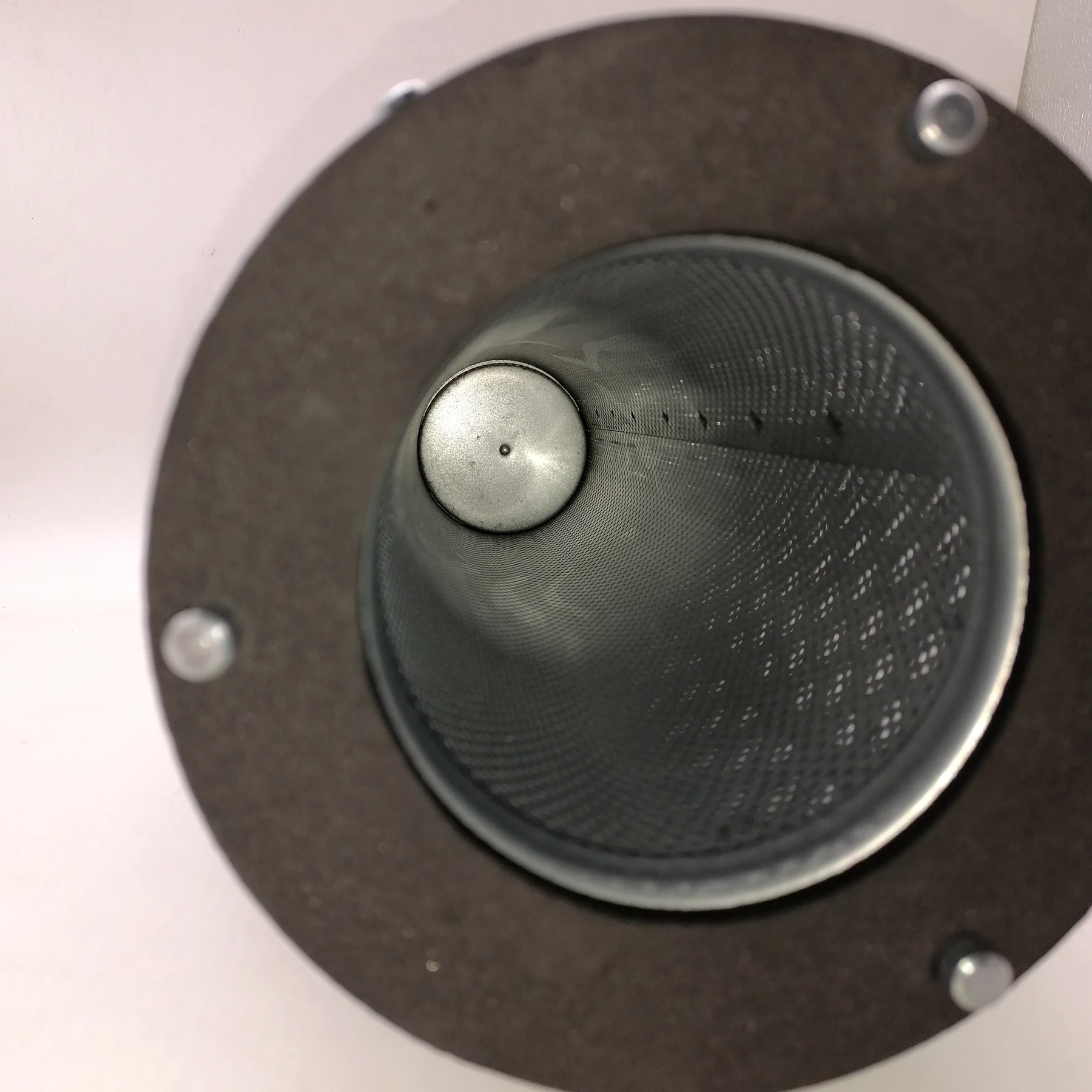

gas turbine air intake filter

By using high-quality air intake filters, operators can minimize the amount of debris that enters the turbine. This not only prolongs the life of critical components but also helps maintain the turbine's efficiency over time. A clean turbine is a more efficient turbine, translating to lower operational costs and enhanced performance.

Maintenance and Performance Monitoring

Regular maintenance of air intake filters is essential to ensure their effectiveness. Filters can become clogged with pollutants, which restricts airflow and diminishes performance. Operators should implement a routine maintenance schedule that includes checking and replacing filters as necessary, thereby ensuring optimal turbine operation.

In addition to physical maintenance, monitoring the performance of air intake systems through advanced technologies, such as pressure transducers and flow meters, can provide valuable insights. These tools can help identify when filters are becoming less effective, allowing for timely interventions that prevent further issues.

Environmental Considerations

As environmental regulations become increasingly stringent, ensuring that gas turbines operate efficiently while minimizing emissions is imperative. Well-maintained air intake filters not only protect turbine components but also help reduce the environmental impact of turbines. By improving combustion efficiency, cleaner exhaust gases are produced, which can aid in compliance with regulatory standards.

Conclusion

In conclusion, air intake filters are a critical component of gas turbine systems. They protect turbine components, enhance performance, and contribute to overall efficiency. Regular maintenance and monitoring of these filters are vital to ensuring the long-term functionality of gas turbines. As industries continue to prioritize efficiency and environmental responsibility, the role of air intake filters becomes even more significant in achieving these goals. By investing in high-quality filtration systems and adhering to best practices in maintenance, operators can ensure that their gas turbines operate at peak performance, benefiting both their operations and the environment.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: