ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

פבר . 13, 2025 14:57 Back to list

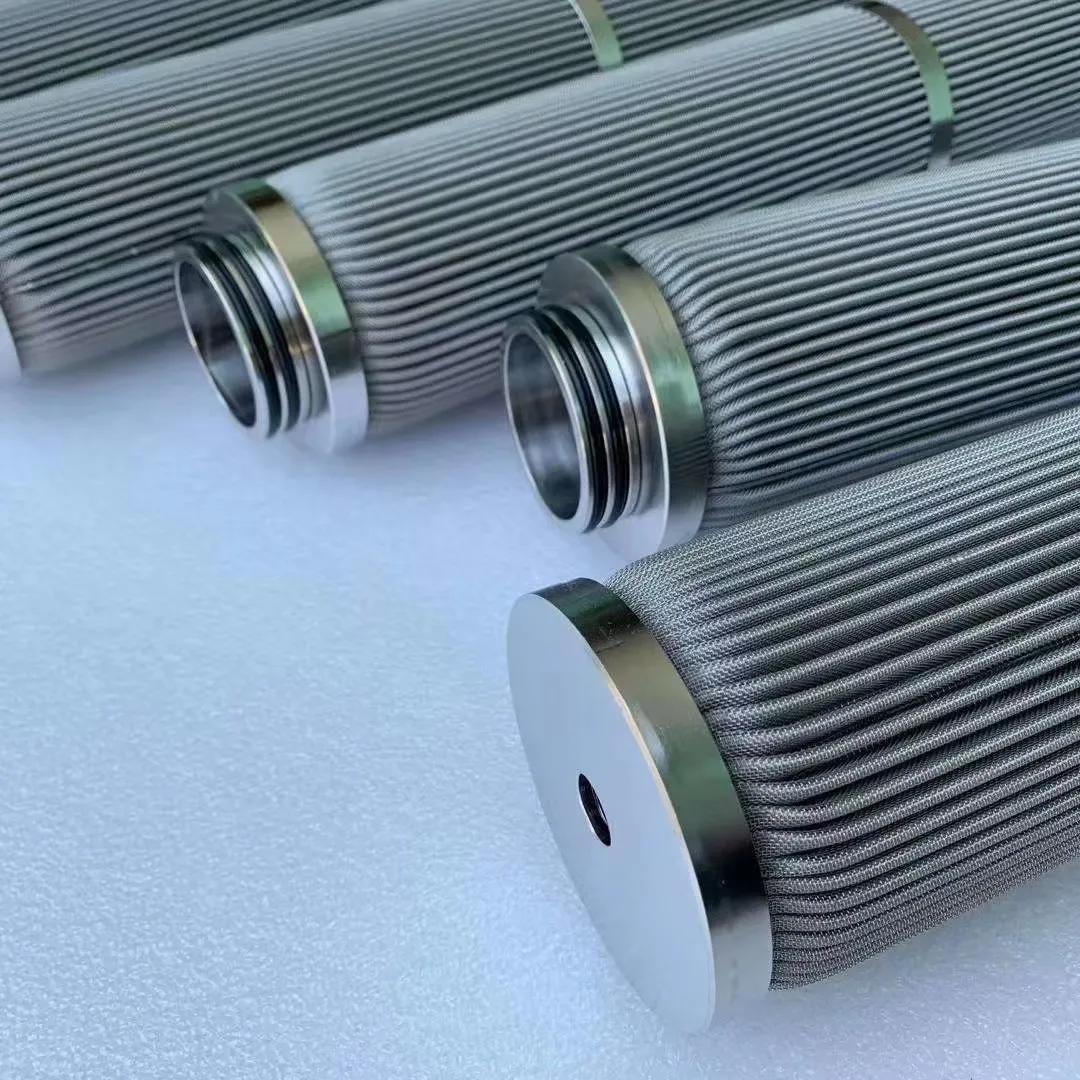

pleated filter cartridge dust collector

Dust collector pleated filters, a fundamental component in maintaining air quality and ensuring smooth industrial operations, have revolutionized the traditional dust collection systems. For industries relying heavily on air purification, understanding the intricacies of these filters not only enhances operational efficiency but secures a healthier, safer working environment, a critical factor in modern industries striving towards sustainable practices.

Authoritativeness in Industry Standards Pioneering advancements in pleated filter technology position them in alignment with global environmental and safety standards. Leading manufacturers adhere to ASHRAE and OSHA guidelines ensuring these filters meet the required efficiency ratings and safety protocols. Pleated filters frequently undergo rigorous testing to affirm their compliance with these standards, consistently achieving MERV ratings indicative of superior air filtration capabilities. Trustworthiness Through Proven Results End-users often report noticeable improvements in air quality and operational efficiency post-installation, reinforcing the reliability of pleated filters. The technology's trustworthiness is validated through data-driven performance metrics; industry reports often cite reduced particulate matter in the air and enhanced equipment longevity due to reduced wear and tear from cleaner air environments. The comprehensive nature of these filters guarantees effectiveness which, when matched with proper maintenance, solidifies their reputation as a trustworthy solution. In an era where industrial operations are increasingly challenged by environmental concerns and economic efficiency, pleated filters emerge as a superior choice. They deliver undeniable benefits across various critical metrics including performance, compliance, and cost-effectiveness. For decision-makers tasked with optimizing air quality solutions, the pivot towards pleated filters represents not only an investment in better technology but a commitment to sustainable and effective operational practices. Elevating air filtration processes with pleated filters fosters an environment that appreciates innovation and values long-term gains. This reflects a deeper understanding of both the operational needs and the overarching environmental responsibilities that modern industries must shoulder. As industries continue to gravitate toward solutions that promise both efficiency and sustainability, pleated filters will be at the forefront, delivering unparalleled results that support industrial growth without compromising ecological integrity.

Authoritativeness in Industry Standards Pioneering advancements in pleated filter technology position them in alignment with global environmental and safety standards. Leading manufacturers adhere to ASHRAE and OSHA guidelines ensuring these filters meet the required efficiency ratings and safety protocols. Pleated filters frequently undergo rigorous testing to affirm their compliance with these standards, consistently achieving MERV ratings indicative of superior air filtration capabilities. Trustworthiness Through Proven Results End-users often report noticeable improvements in air quality and operational efficiency post-installation, reinforcing the reliability of pleated filters. The technology's trustworthiness is validated through data-driven performance metrics; industry reports often cite reduced particulate matter in the air and enhanced equipment longevity due to reduced wear and tear from cleaner air environments. The comprehensive nature of these filters guarantees effectiveness which, when matched with proper maintenance, solidifies their reputation as a trustworthy solution. In an era where industrial operations are increasingly challenged by environmental concerns and economic efficiency, pleated filters emerge as a superior choice. They deliver undeniable benefits across various critical metrics including performance, compliance, and cost-effectiveness. For decision-makers tasked with optimizing air quality solutions, the pivot towards pleated filters represents not only an investment in better technology but a commitment to sustainable and effective operational practices. Elevating air filtration processes with pleated filters fosters an environment that appreciates innovation and values long-term gains. This reflects a deeper understanding of both the operational needs and the overarching environmental responsibilities that modern industries must shoulder. As industries continue to gravitate toward solutions that promise both efficiency and sustainability, pleated filters will be at the forefront, delivering unparalleled results that support industrial growth without compromising ecological integrity.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: