Tel:

+8615930870079

Tel:

+8615930870079

דצמ . 04, 2024 08:24 Back to list

Optimizing Dust Cartridge Performance for Improved Filtration Efficiency and Longevity

Understanding Dust Percentage in Cartridges Importance and Implications

In various industries, especially in the fields of manufacturing and printing, the quality of output is paramount. One often-overlooked aspect that plays a critical role in maintaining this quality is the dust percentage found in cartridges, particularly toner and ink cartridges. Understanding what dust percentage means, its implications, and how to manage it can vastly improve operational efficiency and product quality.

What is Dust Percentage?

Dust percentage refers to the amount of particulate matter that is present within a cartridge. This particulate matter can severely affect the performance of printing devices, leading to issues such as streaks, smudges, and incorrect color reproduction. In many contexts, dust is partially attributed to the wear and tear on the printing hardware or the degradation of the materials used within the cartridges.

Sources of Dust in Cartridges

The dust particles that end up in cartridges can originate from various sources

1. Manufacturing Processes During the production of toner and ink cartridges, small particles may be generated. If the manufacturing environment is not properly controlled, these particles can introduce unwanted dust into the cartridges.

2. Environmental Factors Dust from the surrounding environment can easily find its way into cartridges, especially if they are not sealed tightly or if they are stored in dusty areas.

3. Degradation Over Time As cartridges age, the materials can break down, creating dust. This can result from thermal cycling, wear during usage, or chemical reaction with the ink or toner.

Implications of High Dust Percentage

A high dust percentage in cartridges can lead to several detrimental effects

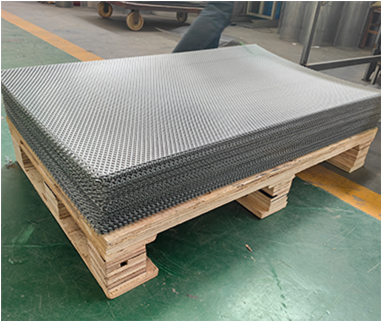

dust cartridge

1. Decreased Print Quality The most immediate consequence is a decline in print quality. Dust can cause blockages, uneven distribution of toner, and overall inconsistencies in print output. This is particularly critical for businesses that rely on high-quality prints for branding and communication.

2. Increased Waste With subpar print quality, users may find themselves wasting paper and ink by printing multiple copies to achieve acceptable results. This not only results in financial losses but can contribute to higher levels of waste, which is an environmental concern.

3. Equipment Damage Excessive dust can accumulate within printers, leading to clogs and misalignments. Over time, this can cause significant wear on components, ultimately leading to costly repairs or replacements.

Managing Dust Percentage

To maintain a low dust percentage in cartridges, several strategies can be employed

1. Environmental Controls Maintaining a clean environment where cartridges are stored and handled can significantly reduce the chances of dust contamination. Investing in air filtration systems can also be beneficial.

2. Quality Control During Manufacturing Manufacturers should implement stringent quality control measures to minimize the introduction of dust during the production of cartridges.

3. Regular Maintenance Regular cleaning and servicing of printers can help mitigate the accumulation of dust within the device itself, ensuring longer life and better performance.

Conclusion

Understanding and managing dust percentage in cartridges is crucial for achieving optimal print quality and maintaining the longevity of printing equipment. By adopting proper storage, handling, and manufacturing techniques, both users and manufacturers can greatly reduce dust contamination, ensuring that their printing devices operate efficiently and produce high-quality results. As the industry continues to evolve, the focus on dust management will likely play an increasingly central role in the overall performance of printing systems.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: