Tel:

+8618931101301

Tel:

+8618931101301

נוב . 19, 2024 09:29 Back to list

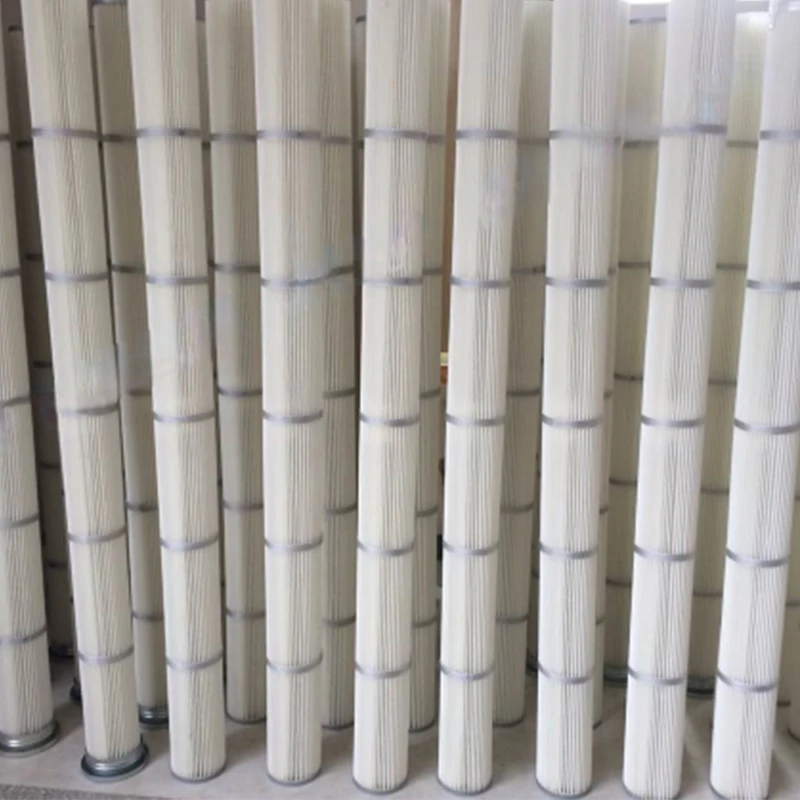

Innovative Cartridge Vacuum Filters for Efficient Liquid Filtration Solutions

Understanding Cartridge Vacuum Filters A Comprehensive Overview

Cartridge vacuum filters are essential components in various industrial processes where the separation of solids from liquids is required. These filters utilize a simple yet effective mechanism to remove impurities from different types of fluids, making them crucial in industries such as food and beverage, pharmaceuticals, wastewater treatment, and more.

How Cartridge Vacuum Filters Work

The operation of a cartridge vacuum filter is based on the principle of vacuum filtration. The system consists of filter cartridges that are designed to hold back solid particles while allowing liquids to pass through. When the liquid mixture is introduced to the filter, a vacuum is created on the other side, drawing the liquid through the cartridges.

The filter cartridges are typically made of various materials, including polymer membranes and woven fabrics, which possess specific pore sizes tailored to the application requirements. As the liquid flows through, solids larger than the pore size are trapped, while the filtered liquid is collected for further processing.

Advantages of Cartridge Vacuum Filters

1. High Efficiency Cartridge filters provide excellent filtration efficiency, capable of trapping even fine particles effectively. This ensures that the final product meets the strict quality standards set by various industries.

2. Cost-Effective Due to their high efficiency and low maintenance requirements, cartridge vacuum filters can lead to significant cost savings. They reduce the need for extensive cleaning processes and minimize waste generation.

3. Versatility Cartridge vacuum filters can handle a wide range of materials and are suitable for various applications, from thick slurries to clear liquids. This versatility makes them a popular choice for many industries.

4. Easy Installation and Maintenance These filters can be easily integrated into existing processing systems. Their design allows for quick cartridge replacement, which minimizes downtime and ensures continuous operation.

cartridge vacuum filter

5. Environmentally Friendly By effectively removing solid waste and impurities, cartridge vacuum filters contribute to more sustainable industrial practices. They help in reducing the environmental impact of wastewater discharge by ensuring compliance with regulatory standards.

Applications of Cartridge Vacuum Filters

Cartridge vacuum filters find applications across several sectors

- Food and Beverage In this industry, they are used to filter juices, oils, and other liquid products to ensure purity and taste.

- Pharmaceuticals Cartridge filters help to remove contaminants from drugs and ensure that the final products are free from harmful particles.

- Wastewater Treatment These filters are instrumental in treating industrial wastewater, allowing for the recycling and safe disposal of water.

- Chemical Processing In chemical manufacturing, cartridge vacuum filters assist in separating reactants and byproducts, contributing to efficient production processes.

Conclusion

In summary, cartridge vacuum filters play a vital role in many industrial applications, ensuring effective separation of solids from liquids. Their efficiency, cost-effectiveness, and versatility make them an attractive option for industries striving for high-quality standards and sustainability. As technology advances, we can expect further enhancements in filter design and performance, paving the way for even greater efficiency in industrial filtration processes. As businesses become more environmentally conscious, the demand for effective filtration solutions like cartridge vacuum filters will continue to grow, solidifying their place in modern industrial operations.

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

Email:

Email: