Tel:

+8615930870079

Tel:

+8615930870079

נוב . 17, 2024 11:33 Back to list

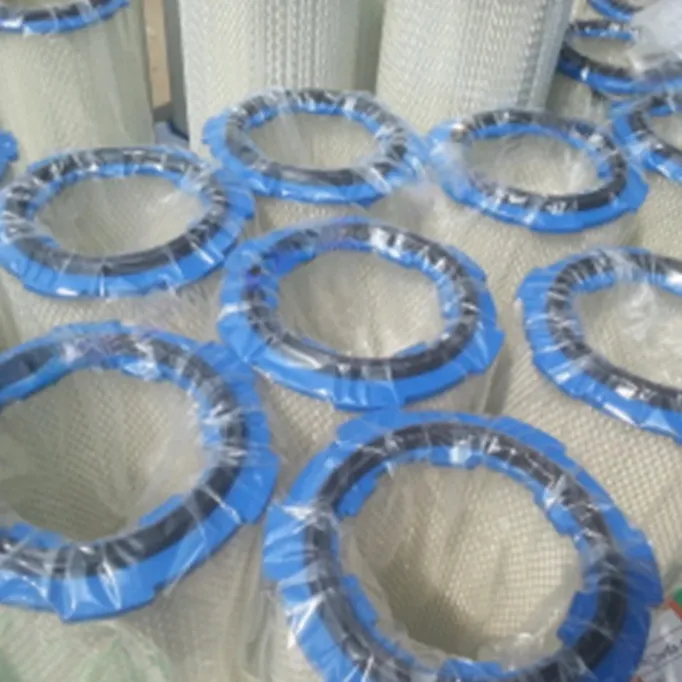

Innovative Cartridge Vacuum Filter Solutions for Efficient Filtration Processes

Cartridge vacuum filters have emerged as an efficient solution in various industrial applications, renowned for their reliability and effectiveness in separating solids from liquids. This type of filter utilizes a unique design that incorporates cartridge elements, providing enhanced filtration performance compared to traditional filtering systems.

In essence, a cartridge vacuum filter operates by employing vacuum pressure to draw liquid through a series of filter cartridges. These cartridges, typically made of high-grade materials such as polypropylene or stainless steel, are designed to capture particles of varying sizes, ensuring that the liquid output is clear and free from contaminants. The process begins when a slurry or liquid mixture is fed into the filtration unit. The vacuum generates a difference in pressure, pulling the liquid through the porous filter medium while leaving behind solid particles, thus achieving effective separation.

One of the primary advantages of cartridge vacuum filters is their versatility. They can be used in a variety of sectors, including pharmaceuticals, food and beverage, chemical processing, and wastewater treatment. For instance, in the pharmaceutical industry, these filters are crucial in ensuring the purity of products by removing impurities that could compromise the quality and safety of medications.

cartridge vacuum filter

Moreover, cartridge vacuum filters are known for their efficient use of space. Their compact design allows for easy installation in facilities where space may be limited. This efficiency extends to maintenance operational aspects; cartridge filters can be easily replaced without requiring significant downtime, promoting continuous operation.

Furthermore, modern cartridge vacuum filters incorporate advanced technologies – such as automated cleaning systems and real-time monitoring – which enhance their performance and longevity. These features minimize the manual labor often associated with traditional filters, allowing operators to focus on more critical tasks while ensuring top-notch filtration standards.

In conclusion, cartridge vacuum filters are pivotal in many industrial processes due to their efficiency, versatility, and ease of maintenance. With ongoing advancements in filtration technology, these systems are likely to become even more integral to various industries, delivering more effective solutions for liquid-solid separation challenges. As industries continue to prioritize purity and efficiency, cartridge vacuum filters will remain at the forefront of technological innovation in filtration processes.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: