Tel:

+8615930870079

Tel:

+8615930870079

אוג . 29, 2024 21:31 Back to list

cartridge vacuum

Understanding Cartridge Vacuum Technology

Cartridge vacuum systems have emerged as a popular choice in various industries due to their efficiency and versatility. This technology harnesses the power of vacuum to manage a plethora of tasks, including material handling, surface cleaning, and even specialized applications in laboratories and manufacturing environments. This article will delve into the workings of cartridge vacuums, their advantages, and the various applications that benefit from this innovative technology.

What is a Cartridge Vacuum?

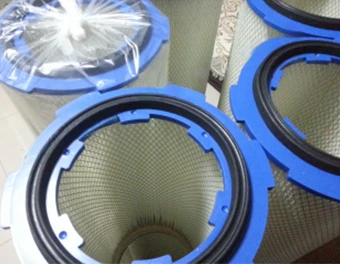

At its core, a cartridge vacuum system is designed to provide powerful suction for the removal of dust, debris, and other particles from surfaces or atmospheres. The key component of this system is the cartridge filter, which is engineered to trap particulates as air passes through. Unlike traditional vacuum systems, cartridge vacuums use a cylindrical filter that offers a larger surface area, resulting in increased efficiency and longer operational life.

In a cartridge vacuum system, the air enters through an inlet, where it is subjected to a pressure differential created by a motor-driven fan. This pressure difference causes air to be drawn in from the environment, passing through the cartridge filter. As the air moves through the filter, particles are caught in the filtration media, while the clean air is expelled back into the environment, often through a controllable exhaust.

Advantages of Cartridge Vacuums

One of the notable advantages of cartridge vacuum technology is its filtration efficiency

. The design of cartridge filters allows for deeper penetration of air, which means finer particles are less likely to escape. This capability is particularly important in industries where maintaining a clean environment is crucial, such as food production, pharmaceuticals, and electronics manufacturing.Another benefit is the ease of maintenance. Cartridge filters can be cleaned using various methods including reverse pulsing, which helps dislodge collected dust and debris without necessitating a complete replacement. This not only saves time but also reduces waste and operational costs.

cartridge vacuum

Additionally, cartridge vacuum systems tend to be more energy-efficient compared to traditional vacuums. The optimized airflow and less back pressure enable these systems to require less power for the same amount of suction, contributing to lower energy bills and an overall reduced carbon footprint.

Applications of Cartridge Vacuums

Cartridge vacuums find their utility across a wide array of applications. In industrial settings, they are used for general housekeeping, eliminating hazardous dust and ensuring cleaner working environments. Moreover, in woodworking shops, cartridge vacuums are essential for collecting sawdust and shavings, which helps in maintaining air quality and workplace safety.

In laboratories, cartridge vacuums are indispensable for safe fume extraction and cleanroom environments. They ensure that airborne contaminants are controlled and that sensitive processes can operate without interference from excess particulates.

The automotive industry also benefits substantially from cartridge vacuums, particularly in manufacturing and assembly processes. These systems help in capturing metal shavings, oil, and other debris, improving both productivity and workplace safety.

Conclusion

In conclusion, cartridge vacuum technology represents a significant advancement in the way industries manage dust and particulates. With their high filtration efficiency, ease of maintenance, and energy-saving features, these systems are adaptable across various applications, enhancing productivity and promoting cleaner environments. As industries continue to prioritize sustainability and efficiency, cartridge vacuum systems will likely play an increasingly central role in operational strategies.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: