Tel:

+8615930870079

Tel:

+8615930870079

אוק . 18, 2024 23:55 Back to list

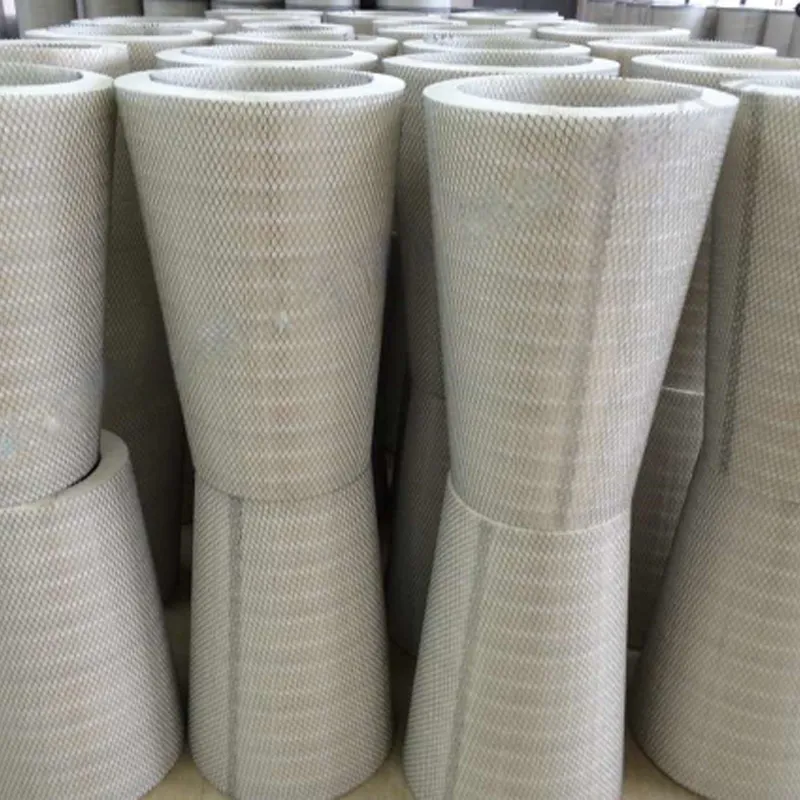

Antistatic Filter Element for Enhanced Protection and Air Quality Control

Understanding Antistatic Filter Elements Importance and Applications

Antistatic filter elements play a critical role in various industrial and commercial applications due to their ability to mitigate static electricity buildup. Static electricity can pose significant hazards in environments dealing with flammable materials, electronic components, or sensitive data equipment. Consequently, the integration of antistatic filter elements has become a necessary measure to ensure safety and maintain optimal operational efficiency.

Most commonly utilized in cleanrooms, electronic manufacturing facilities, and packaging operations, these filter elements are designed to prevent the accumulation of dust, particles, and contaminants while also dissipating static charges. The materials used in an antistatic filter often exhibit electrical conductivity or antistatic properties, which help neutralize static charges that can cause ignition or damage to sensitive components.

Antistatic filter elements are engineered with specialized fibers that blend traditional filter materials with conductive agents. These agents allow the filter to provide a grounding effect, directing static electricity away from critical areas. This enhances not only the safety of the surrounding environment but also the longevity and performance of machinery and electronics by reducing the risk of ESD (Electrostatic Discharge) damage.

antistatic filter element

In areas where volatile substances are present, antistatic filters are essential. Static discharge can easily ignite vapors and pose serious risks, making the use of antistatic systems a mandatory regulatory requirement in many industries, including pharmaceuticals and petrochemicals. Additionally, in the electronics sector, the presence of static can severely affect microchips and other delicate electronic devices, leading to malfunctions or failures.

Moreover, these filters can be tailored to meet specific needs, varying in size, porosity, and antistatic properties depending on the application. Regular monitoring and maintenance of antistatic filters are crucial, as their effectiveness can diminish over time due to accumulation of particles or wear and tear.

In conclusion, antistatic filter elements are essential components in safeguarding both personnel and equipment across a range of industries. By controlling static accumulation and enhancing air quality, these filters contribute significantly to operational integrity and safety, ultimately proving their importance in modern industrial applications. As technology progresses, the demand for advanced antistatic solutions will likely increase, fostering innovations that further protect sensitive environments from the perils of static electricity.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: