Tel:

+8615930870079

Tel:

+8615930870079

Oct . 09, 2024 15:49 Back to list

Efficient Vacuum Filter Cartridge Solutions for Optimal Filtration Performance

Understanding Vacuum Filter Cartridges A Key Component in Filtration Technology

Vacuum filter cartridges are an essential component in various industrial and laboratory applications, providing a reliable solution for the separation of solid particles from liquids. As the need for efficient filtration systems grows across multiple sectors—such as water treatment, pharmaceuticals, and food processing—the importance of vacuum filter cartridges continues to increase.

At the core of a vacuum filtration system is the principle of creating a pressure differential. This differential is achieved by using a vacuum pump, which extracts air from the filtration chamber, thereby facilitating the movement of liquid through the filter medium. The vacuum effect aids in drawing the liquid through the filter cake, which forms on the cartridge, thus enhancing the filtration rate and capturing particulates effectively.

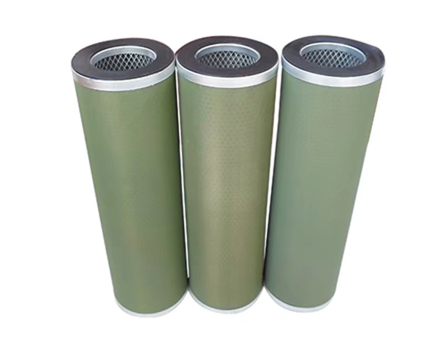

Vacuum filter cartridges typically consist of a hollow cylindrical design, allowing for a large surface area that maximizes filtration efficiency. They can be made from a variety of materials, including polymeric membranes, ceramic, or sintered metal, tailored to meet specific application needs. The choice of material influences the cartridge's chemical resistance, temperature tolerance, and the size of the particles that can be filtered.

vacuum filter cartridge

One of the key advantages of vacuum filter cartridges is their ability to handle thick slurries and high solids content, making them ideal for applications where other filtration methods may fail. This characteristic is particularly beneficial in industries like mining and wastewater treatment, where the volume of suspended solids can be significant. Furthermore, recovery of valuable materials from waste sludge is increasingly important in the circular economy, and vacuum filter cartridges play a crucial role in this process.

Maintenance of vacuum filter cartridges is vital to ensure optimal performance and longevity. Regular cleaning and timely replacement of cartridges not only enhance filtration efficiency but also prevent cross-contamination and potential system failures. Operators must also monitor the vacuum levels and flow rates, as deviations can indicate wear or clogging that may necessitate intervention.

In summary, vacuum filter cartridges are indispensable in modern filtration technology. Their ability to efficiently separate solids from liquids across various industries makes them a valuable asset in achieving high-quality results. As technologies evolve and the demand for sustainable practices intensifies, the design and capabilities of vacuum filter cartridges are likely to advance, further cementing their role in effective filtration solutions. Understanding their functionality, maintenance, and applications will empower industries to leverage the full potential of vacuum filtration systems, ultimately contributing to improved operational efficiency and environmental stewardship.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: