Tel:

+8618931101301

Tel:

+8618931101301

Nov . 29, 2024 17:02 Back to list

Optimizing Turbine Performance with Advanced Filter Technology for Enhanced Efficiency

Understanding Turbine Filters Essential Components for Efficient Energy Generation

Turbines play a crucial role in energy generation across various industries, including wind, hydroelectric, and gas-powered systems. One of the lesser-known yet vital components in these systems is the turbine filter. This article delves into the significance, types, and operational principles of turbine filters, emphasizing their essential contribution to efficient and sustainable energy production.

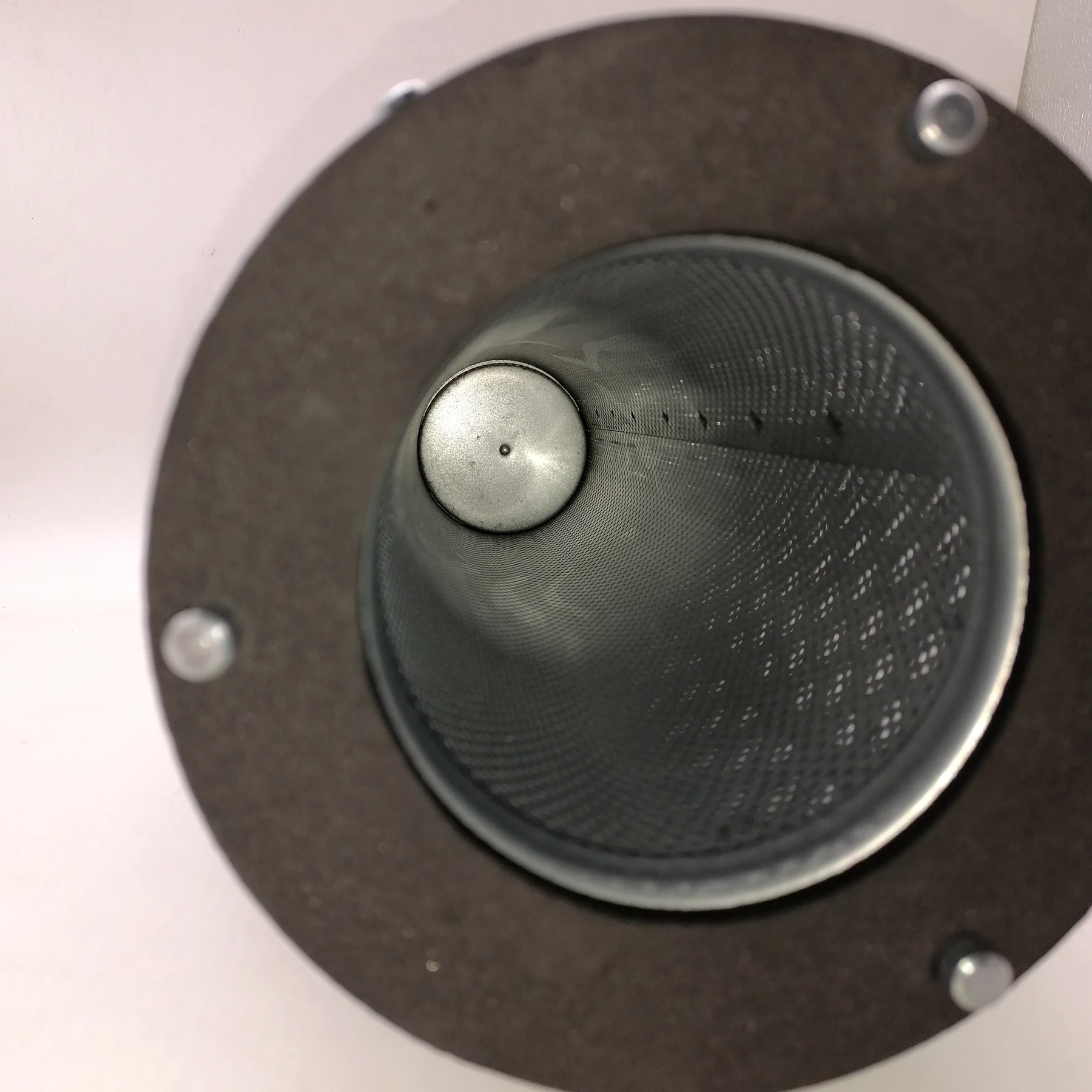

What is a Turbine Filter?

A turbine filter is a device designed to remove contaminants and impurities from the fluid (usually air or water) entering a turbine system. By ensuring that only clean, particle-free fluid reaches the turbine blades or other critical components, turbine filters protect the integrity and efficiency of the entire system. Contaminants like dirt, debris, rust, and other particulate matter can lead to wear and tear, reducing the turbine's effectiveness and lifespan.

Types of Turbine Filters

There are several types of turbine filters, each suited for different applications and operating conditions. Some of the most common types include

1. Air Filters Used primarily in gas turbines, air filters capture dust, pollen, and other airborne particles before they can enter the combustion chamber. Proper filtration is critical for maintaining optimal combustion efficiency and minimizing emissions.

2. Water Filters In hydroelectric power plants, water filters remove organic matter, sediment, and other impurities from the water before it passes through the turbine. This is vital for preventing damage to the turbine blades and ensuring efficient energy conversion.

3. Fuel Filters In combustion turbines, fuel filters clean the fuel before it reaches the combustion chamber. Contaminated fuel can lead to poor combustion performance and increased emissions. Implementing high-quality fuel filtration ensures that only clean fuel is used, optimizing efficiency.

Operational Principles

The effectiveness of a turbine filter is determined by its design, materials, and operational principles. Most filters function based on one or more of the following mechanisms

turbine filter

- Mechanical Filtration This is the most common method, where particles are physically trapped by a filter medium. Filter media can be made from various materials, including paper, fiberglass, and synthetic fabrics, designed to maximize filtration efficiency while allowing adequate flow rates.

- Chemical Filtration In some instances, filters employ chemical processes to remove contaminants. For example, activated carbon filters adsorb harmful gases and vapors, providing an additional layer of protection.

- Centrifugal Separation This technique utilizes centrifugal force to separate heavier particles from the fluid. It’s often used in conjunction with other filtering methods to enhance overall effectiveness.

Importance of Turbine Filters

The importance of turbine filters cannot be overstated. By maintaining the cleanliness of the fluids that power turbines, these filters

1. Enhance Efficiency Clean fluids promote smoother operation and better energy conversion efficiency, reducing operational costs.

2. Extend Equipment Life Regular filtration prevents wear and tear on turbine components, significantly extending their operational life and reducing maintenance expenses.

3. Minimize Downtime By preventing failures caused by contamination, turbine filters help maintain continuous operation, reducing downtime and improving reliability.

4. Environmental Responsibility By improving combustion efficiency and lowering emissions, turbine filters contribute to a more sustainable energy production process.

Conclusion

In summary, turbine filters are critical components in ensuring the efficiency and longevity of various turbine systems. Through mechanical, chemical, and centrifugal approaches, they play a vital role in protecting turbines from harmful contaminants. As industries continue to prioritize sustainable practices and seek to optimize their energy generation processes, the importance of high-quality turbine filters will undoubtedly increase. By investing in advanced filtration solutions, operators can enhance performance and contribute to a cleaner, more efficient energy future.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: