Tel:

+8615930870079

Tel:

+8615930870079

Déc . 03, 2024 22:56 Back to list

Durable Stainless Steel Filter Elements for Enhanced Filtration Efficiency

The Importance and Applications of Stainless Steel Filter Elements

In various industries, the necessity for high-quality filtration systems cannot be overstated, especially in applications that demand durability, efficiency, and cleanliness. One of the pivotal components in achieving these qualities is the stainless steel filter element. Renowned for its corrosion resistance, mechanical strength, and longevity, stainless steel has emerged as a material of choice for constructing filter elements that cater to various filtration needs.

Composition and Properties of Stainless Steel

Stainless steel is an alloy primarily composed of iron, with a minimum of 10.5% chromium content. This chromium forms a protective layer of chromium oxide on the surface, which imparts corrosion resistance to the metal. Depending on the specific grade of stainless steel used (such as 304, 316, or 321), the composition can also include nickel, molybdenum, and other alloying elements to enhance specific characteristics, such as strength, temperature resistance, or oxidation resistance.

The inherent properties of stainless steel make it exceptionally suitable for filter elements. It is not only resistant to rust and staining but also has a high melting point, making it ideal for high-temperature applications. Moreover, the mechanical strength of stainless steel allows for the construction of filter elements that can withstand high pressure and harsh working conditions.

Applications of Stainless Steel Filter Elements

Stainless steel filter elements are widely utilized across various sectors, including

1. Oil and Gas In oil refineries, stainless steel filters are crucial for removing contaminants from crude oil and associated fluids. They ensure that the final product is free of impurities, thus maintaining the integrity of machinery and downstream processes.

2. Chemical Processing The chemical industry demands filtration systems that can handle aggressive chemicals without degrading over time. Stainless steel filters are ideal for removing particulates from fluids and gases, thereby protecting equipment and ensuring product purity.

3. Food and Beverage The food and beverage industry requires stringent hygiene standards. Stainless steel filter elements are favored for their non-reactive qualities, which prevent contamination and maintain the taste and quality of food and beverages.

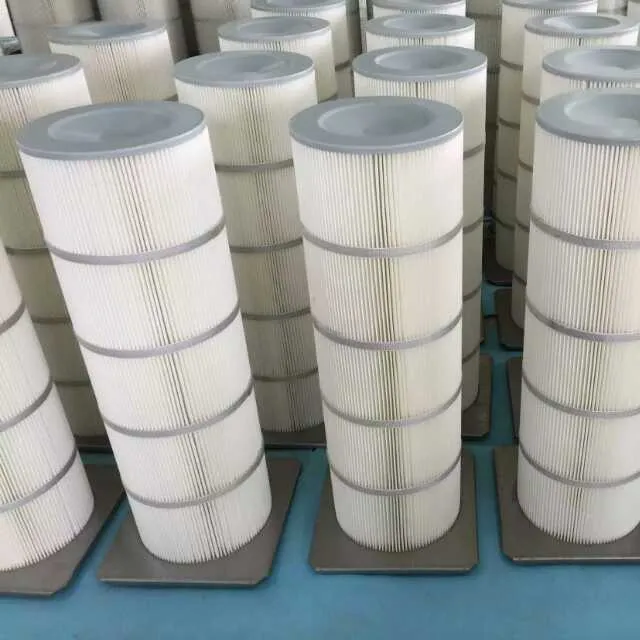

stainless steel filter element

4. Pharmaceuticals In pharmaceutical manufacturing, filtration is critical to ensure that products are free from contaminants. Stainless steel filters can effectively remove particulates while meeting stringent regulatory requirements, making them essential in this field.

5. Water Treatment Stainless steel filter elements play a crucial role in water purification processes. They are used in various applications, from industrial wastewater treatment to municipal water supply filtration, ensuring the removal of sediments and pollutants.

Advantages of Using Stainless Steel Filter Elements

The advantages of stainless steel filter elements extend beyond their applications

- Durability Stainless steel filters can last significantly longer than their plastic or paper counterparts, reducing the need for frequent replacements and minimizing overall operational costs.

- Cleanability Stainless steel material allows for easy cleaning and maintenance, which is vital in industries with stringent cleanliness requirements. They can often be backflushed or chemically cleaned without degrading the filter's integrity.

- Temperature Resistance The ability of stainless steel to perform reliably at high temperatures ensures that these filter elements can be used in demanding applications, such as fuel filtration in engines or high-pressure steam systems.

- Eco-Friendly Stainless steel is fully recyclable, making it a more sustainable choice for filtration solutions compared to disposable filters made from synthetic materials.

Conclusion

In summary, stainless steel filter elements are an indispensable component of modern filtration systems across various industries. Their unique properties and advantages, such as durability, corrosion resistance, and ease of cleaning, make them ideal for applications where performance and reliability are crucial. As industries continue to prioritize efficiency and sustainability, the importance of stainless steel filters is likely to grow, reaffirming their role as a mainstay in the world of filtration technology. Investing in high-quality stainless steel filter elements can lead to improved operational efficiency, reduced costs, and enhanced product quality, making them an essential consideration for businesses aiming to optimize their filtration processes.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: