Tel:

+8615930870079

Tel:

+8615930870079

Oct . 04, 2024 10:12 Back to list

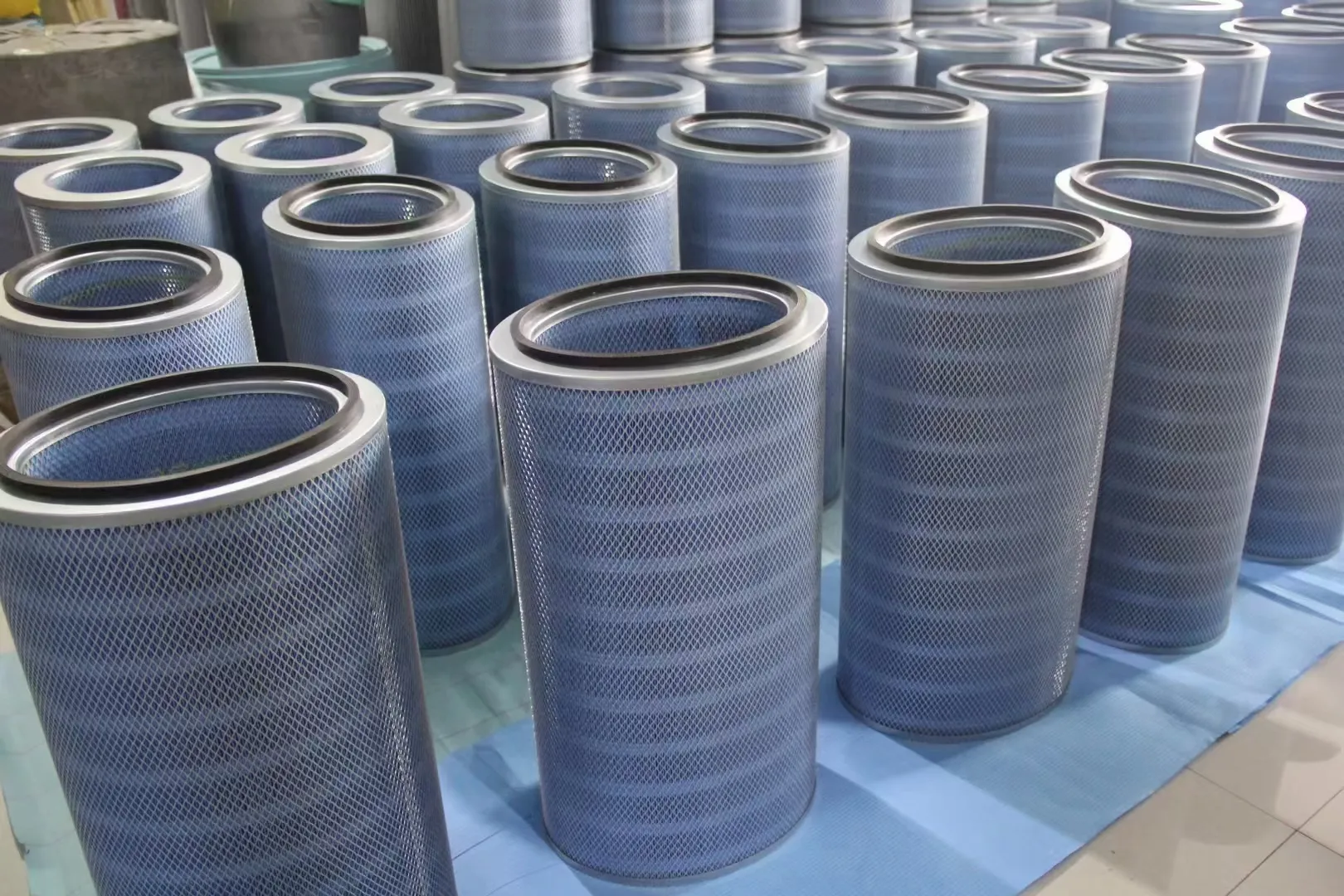

High-Performance Stainless Steel Filter Element for Enhanced Filtration Efficiency and Durability

The Versatility and Importance of Stainless Steel Filter Elements

In various industries, filtration is a critical process that ensures the quality and purity of products. One of the most reliable and widely used materials for filtration applications is stainless steel, particularly in the form of filter elements. Stainless steel filter elements are known for their durability, chemical resistance, and ability to withstand high temperatures and pressures, making them ideal for a wide range of applications.

What are Stainless Steel Filter Elements?

Stainless steel filter elements are components used in filtration systems to separate contaminants, particulates, and impurities from liquids or gases. These elements are typically made from various grades of stainless steel, which are selected based on their specific properties and the requirements of the filtration process. Common grades include 304, 316, and 316L stainless steel, each offering different levels of corrosion resistance and mechanical strength.

Advantages of Stainless Steel Filter Elements

1. Durability One of the most significant advantages of stainless steel filter elements is their mechanical strength. They can withstand harsh environments and are less likely to be damaged compared to other materials like plastic or cloth filters. This durability translates to longer service life and reduced replacement costs.

2. Chemical Resistance Stainless steel is inherently resistant to a wide variety of chemicals, including acids, alkalis, and solvents. This resistance makes stainless steel filter elements suitable for use in chemical processing, pharmaceuticals, food production, and other applications where chemical exposure is a concern.

3. High-Temperature Tolerance Many industrial processes operate at elevated temperatures. Stainless steel filter elements can maintain their integrity and performance under high-temperature conditions, making them suitable for applications in the oil and gas industry, as well as in power generation.

4. Ease of Cleaning and Maintenance Stainless steel filter elements can be cleaned and reused, which is an ecological benefit. This is particularly important in industries that require stringent hygiene standards, such as food and beverage or pharmaceuticals. Their ability to be backwashed allows for efficient maintenance, reducing downtime.

5. Customizable Designs Stainless steel filter elements can be manufactured to meet specific application needs. This includes variations in pore size, thickness, and configuration, allowing for tailored solutions in various processing scenarios.

stainless steel filter element

Applications of Stainless Steel Filter Elements

Stainless steel filter elements find applications in numerous fields, including

- Oil and Gas In the extraction and refining of oil and gas, filtration is essential for removing contaminants from crude oil and natural gas. Stainless steel filters are used to enhance the quality of the end products.

- Pharmaceuticals In pharmaceutical manufacturing, maintaining the purity of products is critical. Stainless steel filters ensure that no contaminants compromise the safety and efficacy of drugs.

- Food and Beverage Processing Compliance with health regulations and quality standards makes stainless steel filters a preferred choice in the food and beverage industry. They are used in the filtration of water, syrups, oils, and more.

- Chemical Processing Due to their chemical resistance, stainless steel filter elements play a vital role in the filtration of process fluids in chemical manufacturing.

- Water Treatment In municipal and industrial water treatment facilities, stainless steel filter elements are used to remove particulates from water sources, ensuring clean and safe water for consumption and other uses.

Conclusion

Stainless steel filter elements are indispensable tools in filtration technology, offering numerous advantages such as durability, chemical resistance, and the ability to withstand extreme conditions. Their versatility allows them to be employed across various industries, contributing significantly to product quality and safety. As industries continue to evolve and demand more efficient and reliable filtration solutions, the role of stainless steel filter elements will undoubtedly become even more prominent. Investing in quality filtration systems with stainless steel elements is not only a practical choice but also a step towards sustainable and responsible manufacturing practices.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: