Tel:

+8615930870079

Tel:

+8615930870079

Juil . 31, 2025 04:20 Back to list

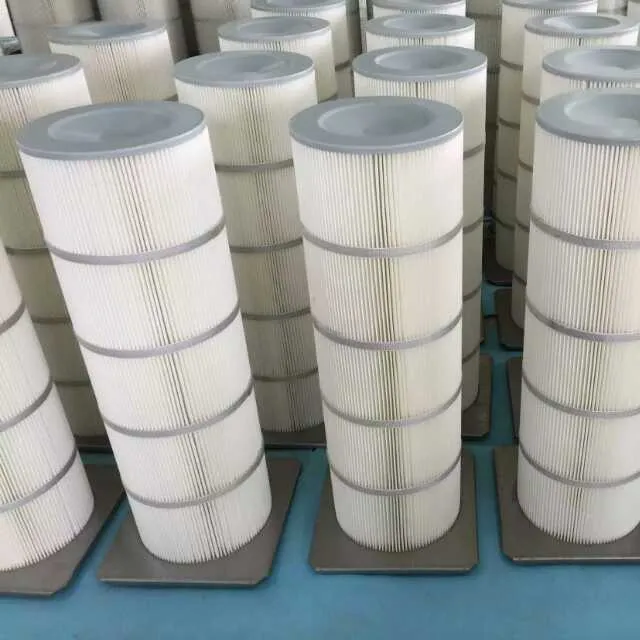

Premium Dust Collector Filter Cartridges | Efficient Dust Removal

1. Industry Trends & Growing Demand for Cartridge Dust Collector Filter Technology

The global demand for dust collector filter cartridge solutions is projected to reach $15.4 billion by 2028 (Source: MarketsandMarkets), driven by stricter government regulations on industrial air emissions and the move towards higher production efficiency in sectors such as petrochemicals, metallurgy, composites processing, and water treatment.

Cartridge dust collector filters offer superior efficiency compared to traditional bag filters, especially in removing ultra-fine, hazardous particulates (dust extractor filter cartridge systems.

2024-2027 Industry Growth - Sector-wise Adoption (%)

- Petrochemicals: process gas filtration, VOC emission control

- Metallurgy: sintering, foundry, welding fume dedusting

- Sandblasting/Surface Treatment: operator & product protection

- Municipal Waterworks: odour control, coarse/ultrafine particle trapping

2. Key Parameters of Dust Collector Filter Cartridge: Market Comparison

| Model | Filtration Efficiency (%) | Media Material | Max. Operating Temp (°C) | Initial Pressure Drop (Pa) | Dimensions (mm) | Lifespan (h) |

|---|---|---|---|---|---|---|

| Industrial Filter Cartridge Sandblasting | 99.97 (at 0.3µm) | Cellulose/ Polyester+ Nanofiber* | 110 | 145 ±15 | Φ325×660 | >8000 |

| Standard Cartridge Filter (Global Avg.) | 97.5 | Polyester / Cellulose blend | 75 | 185 ±20 | Φ325×600 | 4000-7000 |

| HEPA Cartridge (For Cleanrooms) | 99.99 (0.3µm) | PTFE Membrane | 70 | 100 ±12 | Φ350×660 | 5000-9000 |

3. Manufacturing Process of Dust Collector Filter Cartridge (Full Specs)

- 1Raw Material Sourcing: High-grade polyester, cellulose, and nanofiber nonwoven fabrics from ISO 9001-certified suppliers.

- 2Precision Pleating: Media pleated on CNC-controlled machines (±0.2mm tolerances) to maximize surface area and promote uniform airflow.

- 3End Cap/Inner Core Construction: Made from galvanized steel or 304/316 stainless steel using deep-drawing and CNC-lathing, providing corrosion resistance and robust durability.

- 4Epoxy/Polyurethane Potting: Adhesive applied at caps ensures airtight seal, preventing particle bypass.

- 5Assembly & Leak Test: 100% leak test per EN 1822-5 standard; random samples undergo pressure pulse test at 1.6×max working pressure.

- 6Final Inspection: Each unit barcoded and logged for traceability; tested for dimension compliance, pressure drop, and filtration flow.

- ISO 16890 for particulate filtration

- EN 779:2012 (Europe), ANSI Z9.2 (USA)

- RoHS, REACH compliance for materials

- Optional FDA-compliant media upon request

4. Technical Advantages: Why Choose Our Dust Collector Filter Cartridge?

- Superior Filtration Efficiency: Up to 99.97% at 0.3μm dust size, proven by ISO/EN/ANSI tests.

- Extended Service Life: Durable pleated media construction—service life exceeds 8,000+ hours in continuous operations, minimizing maintenance downtime.

- Material Excellence: Composite nanofiber, UV-resistant, and hydrophobic coatings prevent blinding and chemical attack, ideal for corrosive environments (metallurgy, chemical plants).

- Reduced Energy Consumption: Low pressure drop design (starting at 145Pa) means lower fan power and operational cost.

- Robust Mechanical Construction: CNC-welded steel core, galvanized or SS316 end plates, anti-crush design for negative/positive pressure systems.

- User Customizable: OEM/ODM dimension & interface, gasket, and media options available.

5. Application Scenarios: From Sandblasting to Waterworks

- Sandblasting Booths: Effective removal of silica dust and metallic particulates, preventing operator exposure and prolonging machine life.

- Welding & Metal Fabrication: Captures ultrafine metal fumes and alloy dusts—improving workplace air quality and reducing EPA risk.

- Petrochemical Plants: Dust collector filter cartridge guards compressor and critical equipment from catalyst fines.

- Composite Material Workshops: Mitigates inhalation hazard of glass fiber, aramid, or carbon particulate.

- Municipal Water Plants: Used in odour control and particulate abatement from chemical feed storage & dosing rooms.

Case Study: Sandblasting Facility Retrofit (2023)

Solution: Replaced legacy filters with dust collector filter cartridge.

Results:

- Dust emissions at exhaust reduced by 92% (measured per EN 13284-1: ≤1.2mg/m3 vs. original 13mg/m3).

- Average filter replacement cycle doubled from 6 to 13 months.

- Energy consumption of system fan reduced by 14% due to lower pressure drop.

6. Vendor Comparison: How Does Our Cartridge Dust Collector Filter Outperform?

| Brand | Certifications | Customization | Average Lead Time | Warranty | Major Clients |

|---|---|---|---|---|---|

| ONLYFILTER | ISO 9001, ISO 16890, EN 779, FDA on req. | Yes (OEM/ODM, various media & sizes) | 9-15 working days | 18 months | SINOPEC, Unilever, Siemens, GE |

| Generic Importer | ISO 9001 (often self-reported) | Limited (off-the-shelf) | 20-40 days | 6 months | Industry SMEs, resellers |

| Premium US/EU Brand | ISO 16890, EN 1822, FDA option | Conditional; often high MOQ | 25-50 days | 12-24 months | BASF, ExxonMobil, Honeywell |

7. Custom-Made Dust Collector Filter Cartridge Solutions

Looking for filter cartridges tailored to your application, flow rates, or contaminant profile? ONLYFILTER's engineering team offers:

- Support for non-standard dimensions, unusual installation interfaces, and specific gasket compositions (EPDM, Silicone, Viton®).

- Choice of advanced media: high-temp aramid, PTFE-coated anti-static, hydrophobic, bacteriostatic.

- Optimized pleat design for ultra-fine dusts (

- Logo branding, colored end-caps, RFID/barcode for traceability.

8. Technical FAQ: Cartridge Dust Collector Filter

-

Q1. What materials are used for your dust collector filter cartridge media?A1. Our cartridges utilize synthetic polyester or cellulose-based nonwoven media, optionally enhanced with nanofiber, PTFE, anti-static or flame-retardant coatings. End caps and support cores can be constructed from galvanized steel or SS304/316 for chemical resistance.

-

Q2. What is the standard filtration efficiency?A2. The tested filtration efficiency for our standard cartridge models is up to 99.97% (at particle size 0.3μm), validated per ISO 16890.

-

Q3. What dimensional sizes are available?A3. Common dimensions include Φ325×660mm, Φ350×660mm, and custom tube-sheet or flange types. Height, OD, ID, end fixture, and gasket shape can be customized per your duct/collector specs.

-

Q4. What are typical installation standards?A4. Our cartridge dust collector filter conforms to EN 60335-2-69, ANSI Z9.2 and OEM dust extractor fitments with snap-lock, clamp, or flange-mounting.

-

Q5. How often should I change my filter cartridges?A5. Replacement intervals depend on dust loading, but our dust extractor filter cartridge is rated for 8,000-10,000+ hours under typical industrial loads. Pressure drop monitoring and visible end-of-life indicators assist in timely replacement.

-

Q6. Are your products certified?A6. Yes, ONLYFILTER cartridges are ISO 9001, ISO 16890, and RoHS/REACH compliant, with FDA media available on demand.

-

Q7. Can you provide anti-static or high-temperature dust collector filter cartridge options?A7. Absolutely. We offer specialist anti-static (≤106Ω resistivity) and high-temp (up to 250°C, e.g. aramid media) models for explosion-prone or hot gas dust sources.

9. Delivery Cycle, Warranty & Customer Support

- Fast Production Lead Time: Standard models ship in 9-15 working days (custom: contact for confirmation).

- Comprehensive Warranty: 18 months for cartridge hardware and media against manufacturing defects or early failure (details).

- Customer Support: Pre- and post-sale tech support, documentation, and lifetime application advice via phone or email. Installation supervision upon request.

- Traceability: All shipped cartridges barcoded, QC-certified, and logged per batch for complete traceability.

• Selecting Dust Collector Filter Media – Chemical Engineering Online (2023)

• Filtration News – Peer-reviewed industry insights

• Industry Case Studies & Technical FAQ – Eng-Tips Dust Collection Forum

• ISO 16890 Air Filter Testing Standard

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: