Tel:

+8618931101301

Tel:

+8618931101301

Déc . 11, 2024 10:11 Back to list

Gas Turbine Air Intake Filter Suppliers and Their Innovative Technologies for Improved Performance

Gas Turbine Air Intake Filter Manufacturers A Comprehensive Overview

Gas turbines are essential components in various industries, including power generation, aviation, and marine propulsion. One critical aspect of their operation is the air intake system, which relies heavily on high-performance air filters. As such, the role of gas turbine air intake filter manufacturers has become pivotal in ensuring the efficiency and longevity of turbines. This article delves into the significance of these manufacturers, the types of filters they produce, and the key players in the industry.

Importance of Air Intake Filters

Air intake filters serve a crucial purpose protecting gas turbines from contaminants such as dust, dirt, and debris that can accumulate in the atmosphere. These particles can lead to erosion, corrosion, and reduced efficiency of the turbine, which in turn affects performance and operational costs. Quality air intake filters ensure a clean supply of air, enhancing turbine efficiency and extending service intervals.

In gas turbines, the quality of the air supply is directly linked to operational performance and maintenance costs. By removing contaminants from the intake air, filters help maintain optimal airflow, improve combustion efficiency, and reduce emissions. Thus, manufacturers play a vital role in the operational success of turbines across sectors.

Types of Air Intake Filters

Gas turbine air intake filters come in various types, each designed to meet specific operational requirements. The primary categories include

1. Panel Filters Typically used in larger gas turbines, these filters are effective in trapping larger particles and are easy to replace.

3. Bag Filters Used in high-efficiency systems, bag filters are made from fabric materials and can trap a wide range of particulate sizes, making them suitable for environments with heavy dust.

4. Electrostatic Filters Utilizing electrostatic charge to capture particles, these filters are highly efficient and can handle varying airflow rates.

5. Cyclonic Separators This technology uses centrifugal force to separate larger particles from the air stream, often used as a pre-filter before traditional filter types.

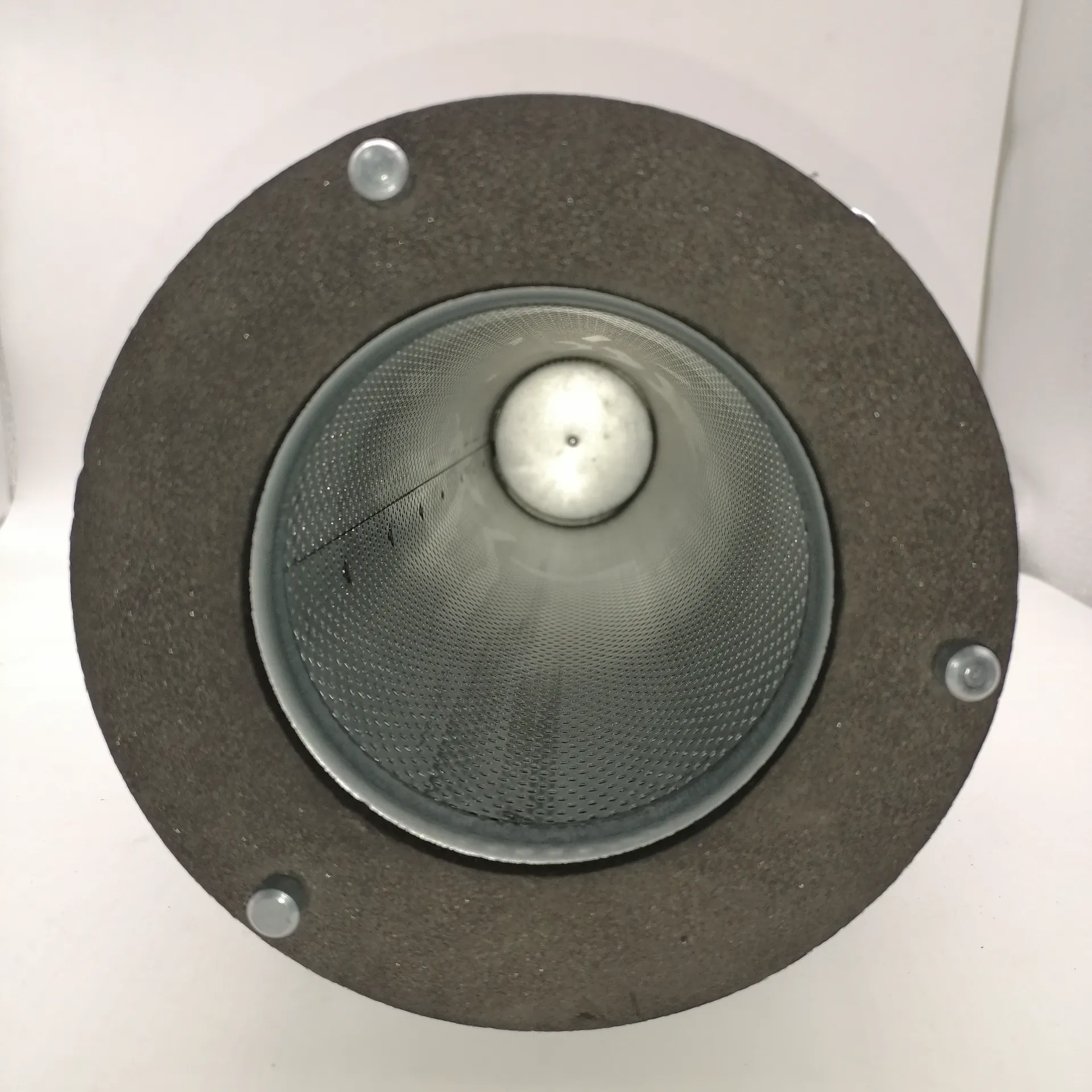

gas turbine air intake filter manufacturers

Leading Manufacturers in the Industry

The market for gas turbine air intake filters includes several notable manufacturers known for their innovation and quality. Some of the leading players include

- Donaldson Company, Inc. With a long-standing reputation in filtration technology, Donaldson offers a wide range of air intake filters designed to enhance turbine performance.

- Camfil AB This manufacturer specializes in high-efficiency filters for gas turbines, providing solutions that not only protect equipment but also improve energy efficiency and reduce emissions.

- Parker Hannifin Corporation Known for its focus on motion and control technologies, Parker also produces filtration solutions that cater specifically to the needs of gas turbine applications.

- Ahlstrom-Munksjö This company provides advanced filtration materials and solutions, helping gas turbine operators reduce maintenance costs through high-quality air intake filtration systems.

Market Trends and Innovations

The gas turbine air intake filter market is poised for growth, driven by increasing energy demands and the rise of renewable energy sources. Manufacturers are focusing on technological advancements to create filters that are not only more efficient but also environmentally friendly. Innovations such as self-cleaning filters and those made with sustainable materials are gaining traction.

Additionally, the trend towards digitalization in monitoring systems is influencing the filtering industry. Smart filters equipped with sensors can monitor airflow and filter performance in real time, enabling proactive maintenance and improving overall turbine reliability.

Conclusion

Gas turbine air intake filter manufacturers play a vital role in ensuring the operational efficiency and longevity of gas turbines. With the growing demand for clean and efficient energy solutions, the importance of high-quality air filters cannot be overstated. As technology continues to advance, manufacturers will need to adapt to meet the ever-evolving challenges of the industry, ensuring that gas turbines can operate reliably and sustainably in the face of increasing environmental regulations and operational demands.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: