Tel:

+8615930870079

Tel:

+8615930870079

Déc . 21, 2024 11:05 Back to list

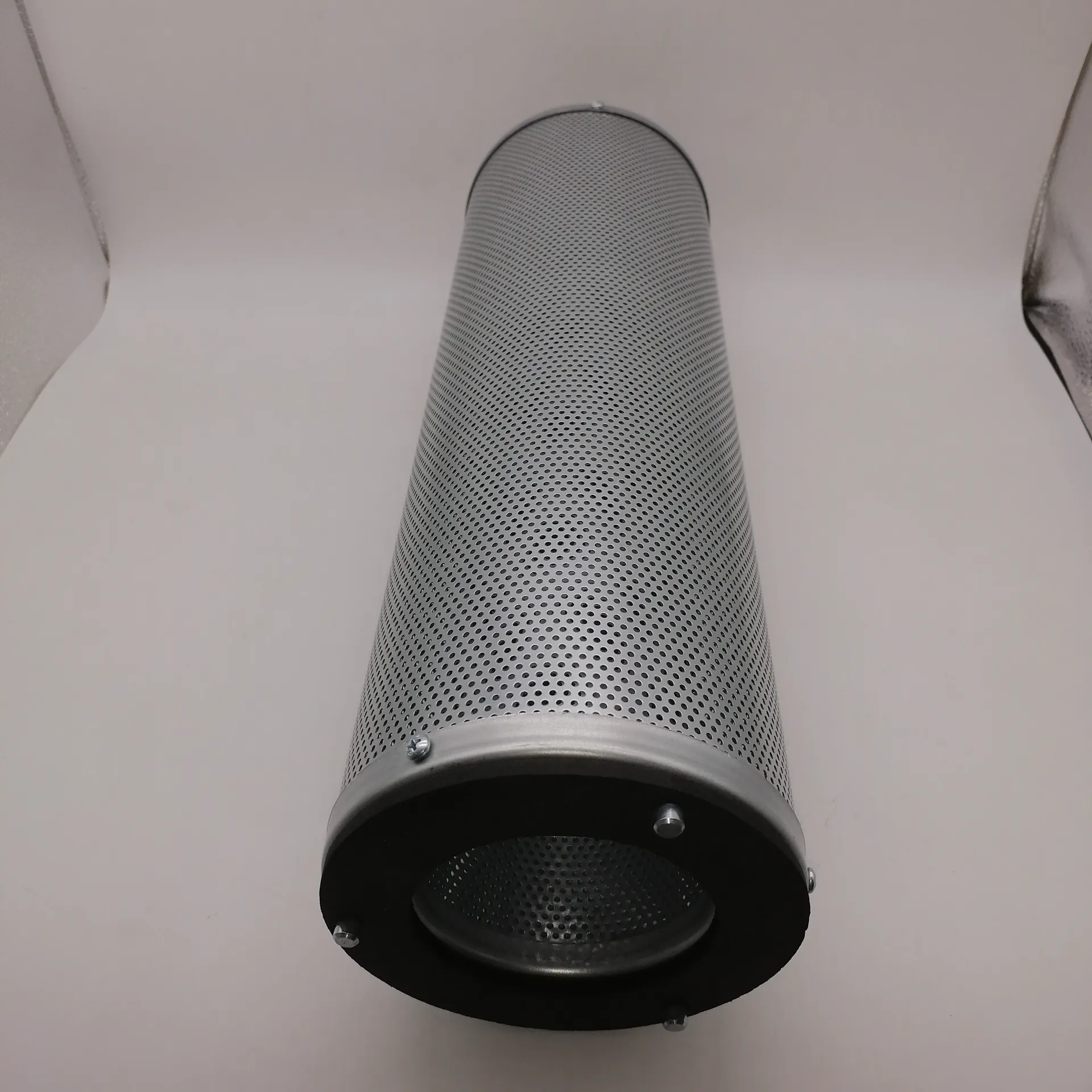

Antistatic Filter Element for Enhanced Performance in Dust Control Systems

Antistatic Filter Elements Understanding Their Importance and Functionality

In a world where electronics rule, static electricity poses significant challenges, especially in environments where sensitive components are handled. This is where antistatic filter elements come into play, providing a crucial layer of protection against electrostatic discharge (ESD) that can jeopardize equipment, lead to data loss, and disrupt manufacturing processes. In this article, we delve into the importance and functionality of antistatic filter elements, examining their construction, applications, and benefits.

What Are Antistatic Filter Elements?

Antistatic filter elements are specialized filtration components designed to minimize the build-up of static electricity in various systems. These filters are typically made from conductive or dissipative materials that effectively neutralize static charges. By incorporating antistatic properties into the design, these elements help prevent the accumulation of dust and particulate matter that can lead to ESD, ensuring the integrity and performance of electronic devices and systems.

How Antistatic Filter Elements Work

The function of antistatic filter elements revolves around their ability to dissipate static charges. They are often integrated into HVAC systems, cleanrooms, and manufacturing areas where electronic components undergo assembly and testing. When air passes through an antistatic filter, the charged particles in the airflow are neutralized due to the conductive properties of the filter material. This minimizes the risk of sparks or discharges that could otherwise damage sensitive electronics.

In practical terms, these filters are constructed using materials like conductive fibers or metallic screens that allow for effective grounding. By creating a pathway for static charges to flow harmlessly away, antistatic filter elements play a vital role in safeguarding electronic equipment.

Applications of Antistatic Filter Elements

Antistatic filter elements find extensive use across various industries. The electronics manufacturing sector relies heavily on these filters to maintain cleanroom environments. Even a small amount of static discharge can result in significant damages to microchips and circuit boards. Therefore, by employing antistatic filters, manufacturers ensure that their production facilities remain free from adverse static effects.

antistatic filter element

Additionally, industries such as pharmaceuticals and food processing, where contamination control is paramount, also benefit from antistatic filter elements. The filters not only help in maintaining air quality but also contribute to minimizing risks associated with ESD in sensitive production processes.

Benefits of Using Antistatic Filter Elements

1. Enhanced Equipment Protection One of the foremost benefits of antistatic filter elements is the protection they provide to electronic equipment. By minimizing static buildup, these filters reduce the likelihood of ESD, which can lead to malfunction or failure of sensitive devices.

2. Improved Air Quality Antistatic filters also play a crucial role in maintaining air purity, particularly in environments susceptible to contamination. By capturing particulate matter while neutralizing static charges, they help maintain a clean and safe atmosphere for sensitive operations.

3. Cost Efficiency While the initial investment in high-quality antistatic filter elements may seem significant, the long-term savings derived from reduced equipment damage and downtime make these filters economically advantageous. Equipment longevity and operational efficiency are paramount in any industry, and these filters contribute positively to both.

4. Compliance with Standards Many industries are subject to stringent regulations regarding environmental control and equipment safety. Using antistatic filter elements helps organizations comply with these standards, ensuring operational legitimacy and safeguarding against potential fines or penalties.

Conclusion

In conclusion, antistatic filter elements are an indispensable component in protecting sensitive electronics from the harmful effects of static electricity. Their unique design and functionality not only enhance equipment longevity but also improve air quality across various industries. As technology continues to evolve, the need for effective static control measures will only increase, making antistatic filter elements essential for any operation dealing with electronic components. By investing in these advanced filtration solutions, businesses can ensure their processes remain efficient, safe, and compliant with industry standards.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: