Tel:

+8618931101301

Tel:

+8618931101301

Nov . 05, 2024 12:58 Back to list

air filter turbine

The Role of Air Filters in Turbine Efficiency

Air filters play a crucial role in the operation and efficiency of turbines, particularly in environments where air quality can significantly impact performance. Turbines, whether they are used in power generation, aviation, or industrial applications, rely on clean air to function optimally. The integration of efficient air filtration systems is essential to enhance the longevity and operational effectiveness of turbines.

Understanding Turbines

Turbines convert kinetic energy from fluids—whether they are gases or liquids—into mechanical energy. In various applications, such as gas turbines in power plants or jet engines in aircraft, the air intake is paramount. For gas turbines, the quality of engine inlet air directly influences overall efficiency and performance. Unfiltered air contains particulates and contaminants that can lead to equipment wear, reduced efficiency, and increased maintenance costs.

The Importance of Air Filtration

Air filtration serves as the first line of defense against pollutants. The primary goal of air filters in turbine applications is to remove particulate matter, dust, and other harmful contaminants from the intake air. This process not only safeguards the turbine components, such as blades and casings, but also ensures that the combustion process in gas turbines is as clean as possible.

When air enters a turbine, it must be as free from impurities as possible. Contaminants can cause combustion inefficiencies, leading to higher fuel consumption and increased emissions. In power generation turbines, this can result in lower output and increased operational costs. Therefore, the implementation of effective air filtration systems is crucial for maintaining both performance and environmental standards.

Types of Air Filters

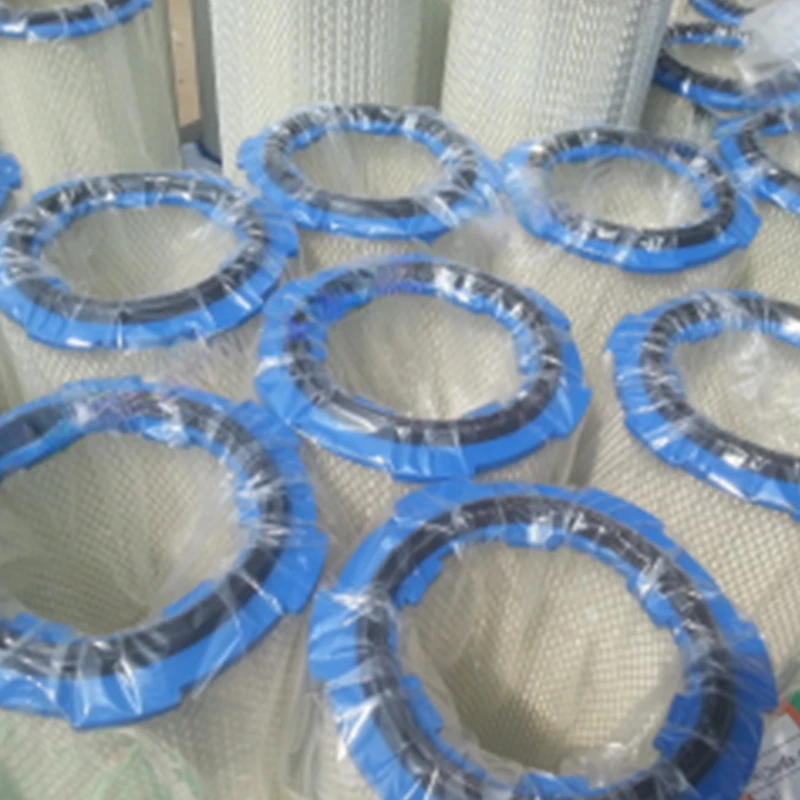

air filter turbine

There are several types of air filters that can be employed in turbine applications. High-efficiency particulate air (HEPA) filters are among the most effective; they can capture 99.97% of particles that are 0.3 microns or larger. These filters are especially valuable in settings where air quality is paramount.

Another common filter type is the electrostatic filter, which uses electrostatic energy to attract and capture particles. This type of filter can achieve high efficiency with lower resistance, allowing for improved airflow while maintaining filtration effectiveness. Additionally, pre-filters can be used to capture larger particles before the air reaches the main filter, thereby prolonging the life of the primary filtration system.

Maintenance and Inspection

Regular maintenance and inspection of air filters are essential to ensure optimal turbine performance. Clogged or dirty filters can create additional strain on turbine systems, leading to decreased efficiency and increased operational risks. Developing a systematic approach to air filter management—including routine checks, replacements, and cleaning—can help mitigate these issues.

Monitoring filters’ pressure drop is one of the best practices in maintaining air filtration systems. An increase in pressure drop indicates that a filter is becoming clogged. Operators should replace filters based on manufacturer recommendations or when the pressure drop exceeds predetermined levels.

Conclusion

In conclusion, air filters are indispensable in ensuring the efficiency and longevity of turbines. With the rising demand for energy and the push for cleaner technologies, the roles of these filters are becoming even more significant. By maintaining stringent air quality standards through effective filtration, operators can enhance turbine performance, reduce operational costs, and minimize environmental impact. The integration of advanced filtration systems in turbine applications is not just a matter of performance; it is a critical component of sustainable and efficient energy production. As technology continues to evolve, so too will the methods we use to keep our turbines operating at their best, underscoring the importance of air filtration in today’s industrial landscape.

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

Email:

Email: