Tel:

+8615930870079

Tel:

+8615930870079

Dic . 20, 2024 18:01 Back to list

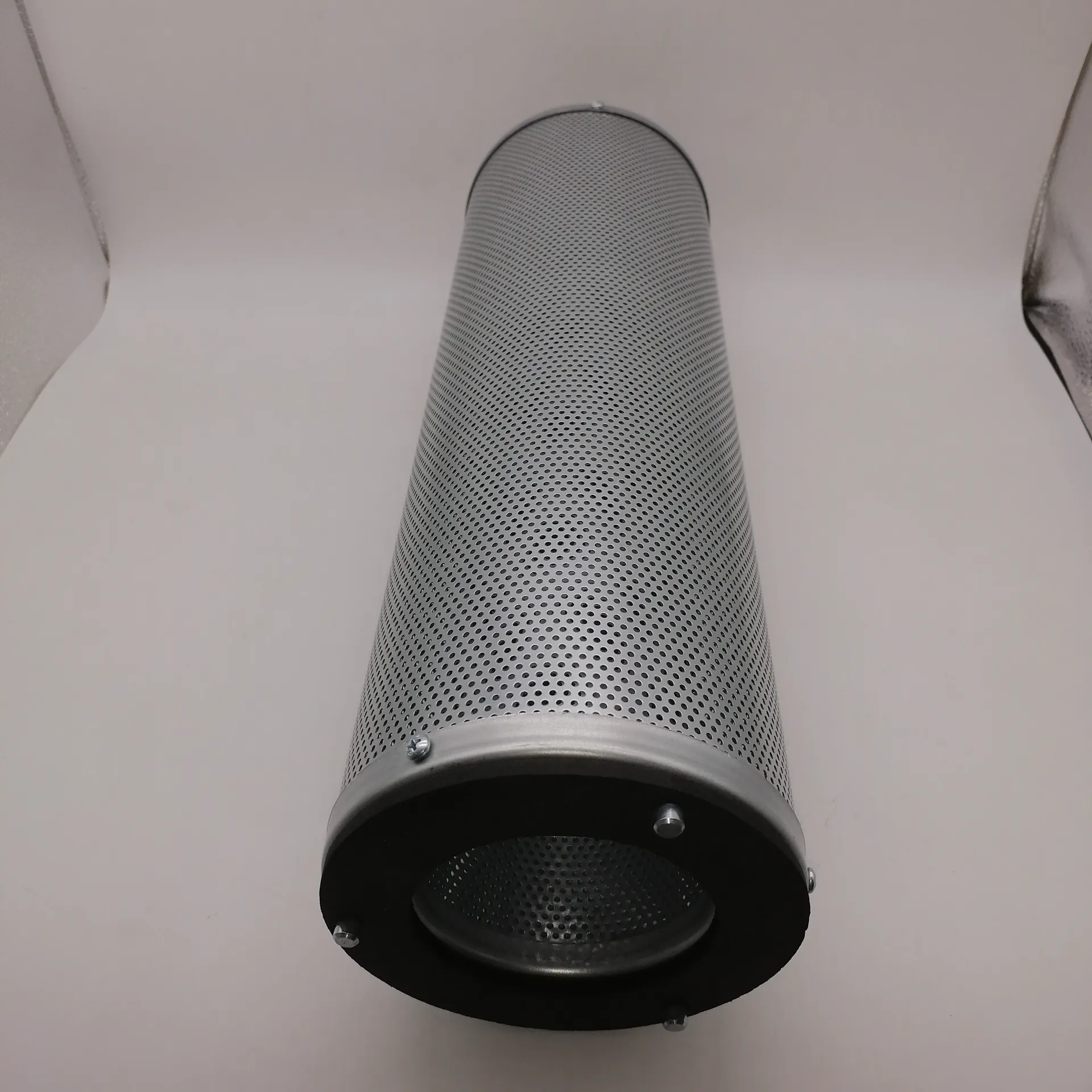

vacuum filter cartridge

Understanding Vacuum Filter Cartridges Function, Types, and Applications

Vacuum filter cartridges are crucial components in various filtration systems used across industries ranging from water treatment to pharmaceuticals. Their design and function are specifically tailored to separate solid particles from liquids through a combination of vacuum pressure and filtration technology. This article explores the fundamentals of vacuum filter cartridges, including their operation, types, and applications.

How Vacuum Filter Cartridges Work

The fundamental principle behind vacuum filter cartridges involves the use of a vacuum to create a pressure differential that draws liquid through a filtering medium. In a typical setup, a containment vessel holds the liquid containing suspended solids. As vacuum pressure is applied, the liquid is pulled through the filter cartridge, which is designed to retain solids while allowing clean liquid to pass through.

A vacuum filter cartridge is generally composed of three main parts the filter medium, the support structure, and the inlet and outlet ports. The filter medium—often made from materials like polyester, polypropylene, or cellulose—determines the size of particles that can be trapped. The support structure provides stability to the filter medium and helps maintain its shape during operation.

Types of Vacuum Filter Cartridges

Vacuum filter cartridges come in various types, each suited for specific applications and requirements

1. Pleated Filter Cartridges These filters have a larger surface area due to their pleated design, allowing for greater filtration capacity and extended service life. They are commonly used in applications requiring high flow rates, such as wastewater treatment and industrial processes.

2. String Wound Cartridges Made from a string material wound around a core, these cartridges are effective in capturing larger particles. They are often used for pre-filtration before finer filtration processes.

3. Depth Filter Cartridges These filters are designed to provide depth filtration, allowing particles to be trapped within the filter medium rather than on the surface. This design is beneficial for removing suspended solids from liquids with variable sizes and shapes.

4. Carbon Filter Cartridges Incorporating activated carbon, these cartridges not only filter physical impurities but also remove odors and chemical contaminants from liquids. They are widely used in drinking water purification and aquarium filtration systems.

vacuum filter cartridge

Applications of Vacuum Filter Cartridges

Vacuum filter cartridges are indispensable in a variety of industries

- Water Treatment In municipal water treatment plants, vacuum filter cartridges help purify water by removing sediments, algae, and other impurities. Effective filtration is essential for ensuring safe drinking water.

- Pharmaceutical Manufacturing In the pharmaceutical industry, vacuum filter cartridges are used to produce ultra-pure solutions by filtering out contaminants that could interfere with product efficacy.

- Food and Beverage Industry Vacuum filtration plays a significant role in clarifying juices, wines, and other beverages by removing solids while preserving flavor and quality.

- Chemical Processing The chemicals industry often utilizes vacuum filter cartridges to separate solid by-products from liquid streams during production, ensuring that the final products meet stringent quality standards.

- Oil and Gas Extraction In oil drilling operations, vacuum filter cartridges can be used to remove unwanted particulates from drilling fluids, thus enhancing the efficiency of the extraction process.

Maintenance and Replacement

To ensure optimal performance, vacuum filter cartridges require regular maintenance and timely replacement. The frequency of replacement depends on factors like the nature of the fluids being filtered, the concentration of solids, and the operational conditions. Monitoring the pressure drop across the cartridge can also serve as an indicator of when to replace it.

Conclusion

Vacuum filter cartridges are essential tools in various filtration applications, providing efficient separation of solids from liquids while ensuring product quality and safety. With advancements in materials and technology, the effectiveness and lifespan of these cartridges continue to improve. Understanding the types and functionalities of vacuum filter cartridges can empower industries to make informed choices that enhance their filtration processes and achieve operational excellence.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: