Tel:

+8618931101301

Tel:

+8618931101301

Nov . 11, 2024 00:17 Back to list

Optimizing Performance with Advanced Turbine Air Intake Filtration Systems for Enhanced Efficiency

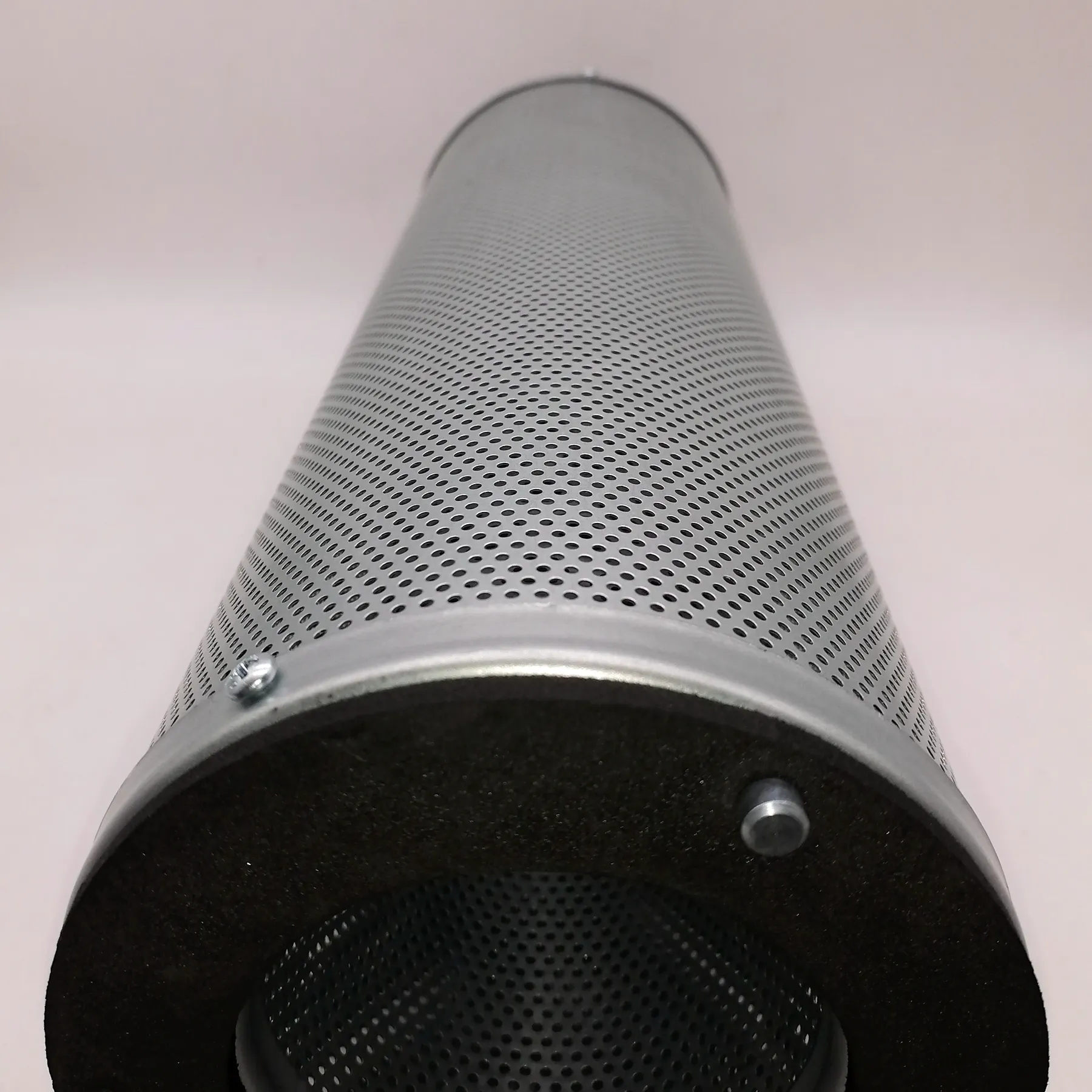

Understanding Turbine Air Intake Filters Their Importance and Functionality

In the world of turbine engines, whether jet engines in aircraft or gas turbines in power plants, efficiency and performance are paramount. One critical component of these systems that often goes overlooked is the air intake filter. Turbine air intake filters play a vital role in ensuring that the air entering the engine is clean, free of contaminants, and conducive to optimal performance. This article delves into the importance, functioning, and maintenance of turbine air intake filters.

The Role of Air Intake Filters

Air intake filters are designed to prevent harmful particles from entering the turbine engine. These particles can include dust, dirt, sand, and other debris that could degrade engine performance, lead to component wear, or cause catastrophic failures. In essence, the air intake filter acts as a guardian, ensuring that only purified air reaches the compressor section of the engine.

For a turbine engine, the efficiency of combustion is directly related to the quality of the air supplied. Contaminated air can lead to incomplete combustion, resulting in reduced power output, increased fuel consumption, and higher emissions. This makes the air intake system, including the filters, a crucial element not only for performance but also for environmental compliance.

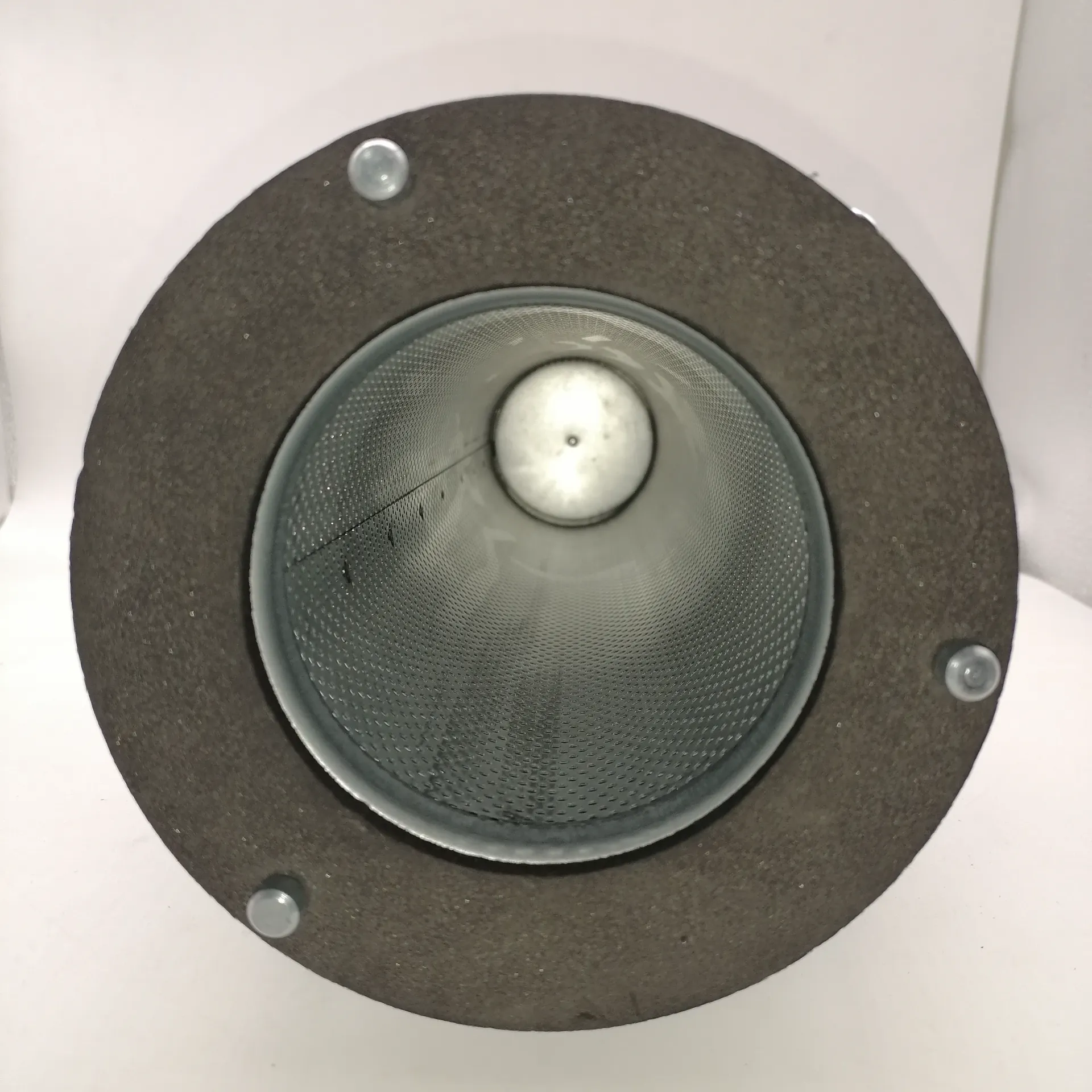

Types of Turbine Air Intake Filters

There are various types of air intake filters used in turbine applications, each suited for specific operational conditions

1. Dry Filters These generally consist of a series of pleated paper or synthetic media designed to capture particulate matter without the use of moisture. They are often lightweight, simple to maintain, and effective for many applications.

2. Oil-Bath Filters These filters utilize a layer of oil to trap dust and dirt. The air passes through the oil, which collects particulate matter before it can enter the engine. While highly effective, they require regular maintenance to ensure the oil remains clean and at an appropriate level.

3. Wet Filters Similar to oil-bath filters but use water instead. These systems can be highly effective in environments with high humidity, as they can capture larger particles while allowing air to flow freely.

turbine air intake filters

4. Electrostatic Filters Utilizing electrostatic principles, these filters attract and capture airborne particles, providing a highly efficient filtration process. However, they may require specialized maintenance and understanding of their operational limits.

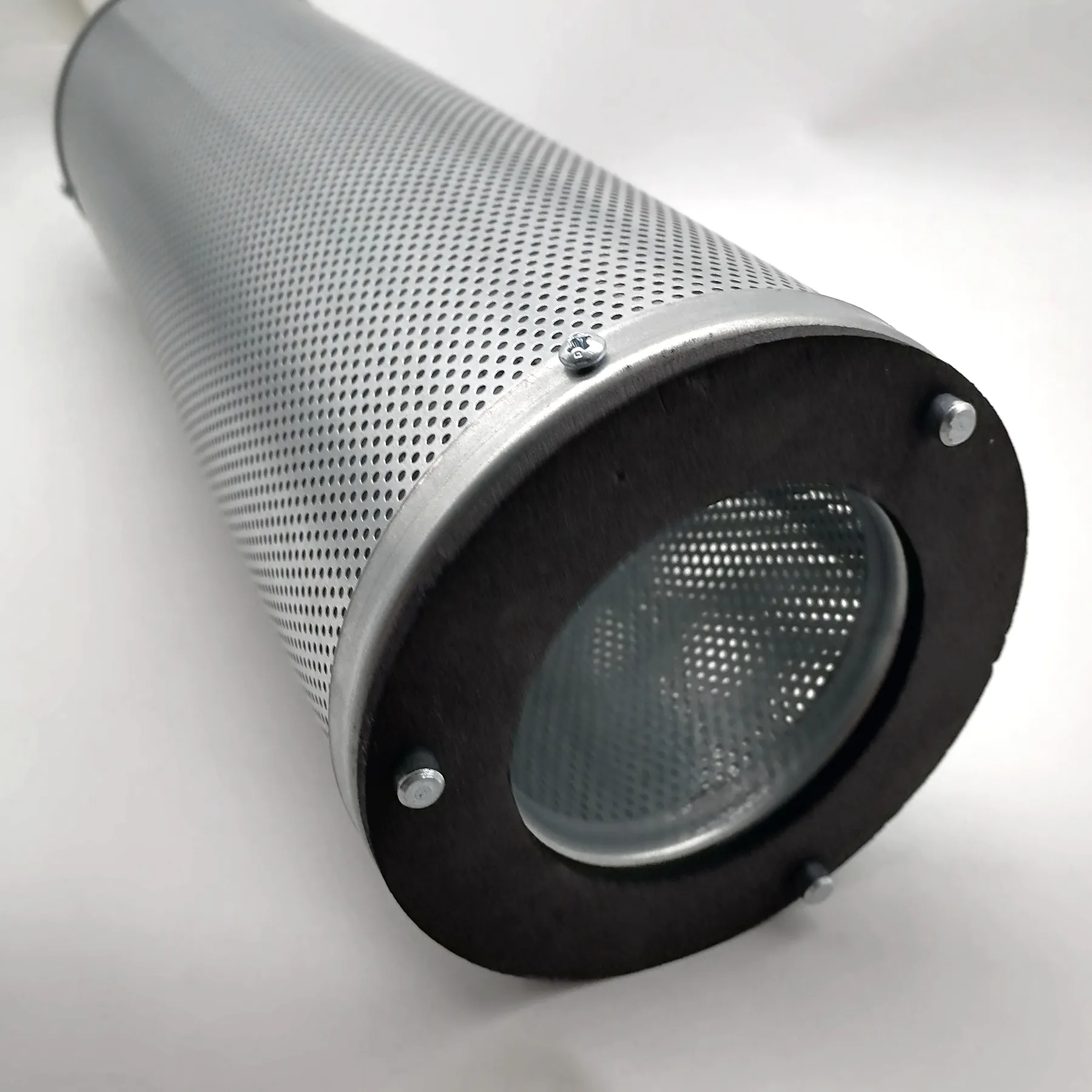

Maintaining Turbine Air Intake Filters

Proper maintenance of air intake filters is crucial for ensuring their efficiency and longevity. Here are some general guidelines

1. Regular Inspection Turbine air intake filters should be checked regularly for any signs of damage or clogging. A thorough inspection is essential, especially after operation in dusty or harsh environments.

2. Cleaning and Replacement Depending on the type of filter used, cleaning may be possible. Dry filters can often be knocked clean, while oil and wet filters may need to be washed with the appropriate solutions. Replacement should be carried out based on the manufacturer’s recommendations or when the filter becomes too dirty to function effectively.

3. Monitoring Performance Keeping an eye on engine performance metrics can help identify issues with air intake filters. A sudden drop in performance or an increase in fuel consumption can indicate that the filter is becoming clogged.

4. Environmental Considerations The operating environment significantly impacts the life of an air intake filter. In extremely dusty or sandy environments, filters may need to be inspected and replaced more frequently.

Conclusion

In summary, turbine air intake filters are a small but essential component of turbine engine operation. Their ability to clean incoming air helps maintain engine performance, fuel efficiency, and overall operational reliability. With various types available, it is vital for operators and maintenance teams to choose the right filter for their specific applications and environments. Regular maintenance and timely replacements will ensure that these systems continue to work effectively, safeguarding the turbine engine and enhancing its longevity. As we continue to push the boundaries of aerospace and energy technologies, the importance of clean air intake in turbine engines cannot be overstated.

-

How to increase the filtration area of pleated dust filter element?NewsMay.13,2025

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

Email:

Email: