Tel:

+8615930870079

Tel:

+8615930870079

Oct . 16, 2024 02:56 Back to list

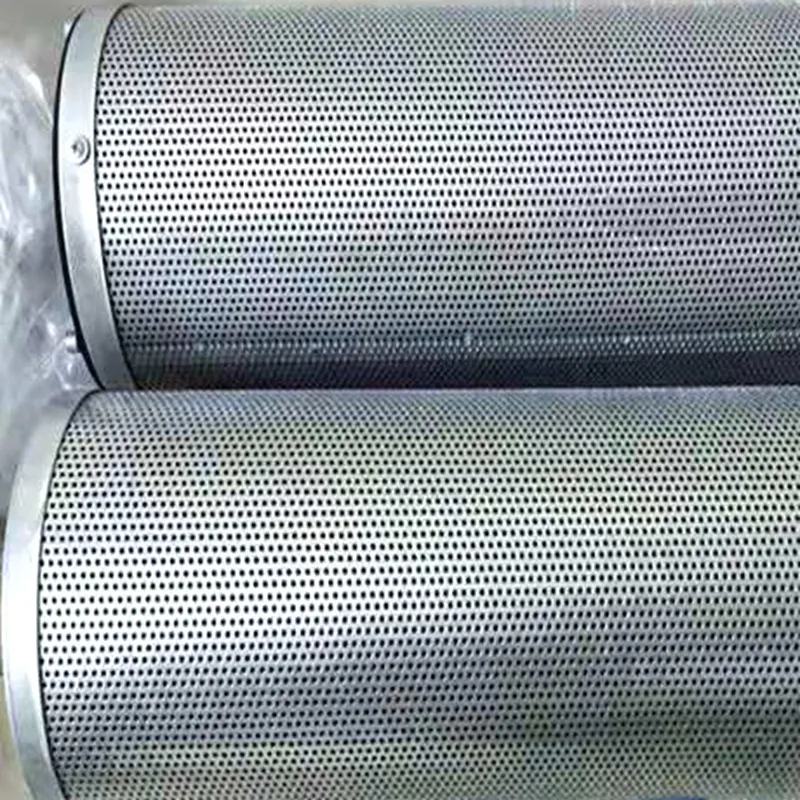

High-Performance Stainless Steel Mesh Filter Cartridge for Efficient Filtration Solutions

The Versatility and Benefits of Stainless Steel Mesh Filter Cartridges

In an increasingly industrialized world, the demand for effective filtration solutions has never been higher. Among various filtration technologies, stainless steel mesh filter cartridges have gained significant traction due to their durability, efficiency, and versatility. These cartridges are essential components in numerous industries, including pharmaceuticals, food and beverage, chemicals, and wastewater treatment, providing reliable filtration for liquids and gases.

What are Stainless Steel Mesh Filter Cartridges?

Stainless steel mesh filter cartridges are cylindrical filters made from woven stainless steel wire mesh. They are designed to trap particulate matter while allowing fluids to pass through. The mesh size can vary, allowing for the specification of different filtration capabilities tailored to the application at hand. Common mesh sizes range from 5 microns to over 100 microns, enabling the filtration of various contaminants from coarse particles to fine debris.

Key Advantages of Stainless Steel Mesh Filter Cartridges

1. Durability and Longevity One of the primary benefits of stainless steel mesh filter cartridges is their remarkable durability. Unlike traditional filters made from paper or polyester, stainless steel does not tear or degrade easily. This makes them ideal for high-pressure applications and extreme temperatures. Furthermore, stainless steel is resistant to corrosion and oxidation, ensuring long life even in harsh environments.

2. Reusable and Recleanable Unlike disposable filters, stainless steel mesh cartridges can be cleaned and reused, significantly reducing waste and operational costs. Various cleaning methods, including backwashing, ultrasonic cleaning, and chemical cleaning, can be employed depending on the type of contaminant trapped within the mesh. This feature not only saves money but also makes them an environmentally friendly choice.

3. Customization Stainless steel mesh filter cartridges can be customized in terms of size, mesh aperture, and length to fit specific filtration needs. This versatility allows industries to tailor their filtration processes according to the characteristics of the fluids being filtered, whether it be oil, water, or even air.

stainless steel mesh filter cartridge

4. High Flow Rates The open structure of stainless steel mesh permits high flow rates, enabling efficient filtration without significantly restricting fluid flow. This is particularly important in processes where maintaining flow is crucial, such as in manufacturing or during wastewater treatment.

5. Chemical Compatibility Stainless steel is compatible with a wide variety of chemicals. This allows these filter cartridges to be used in applications involving aggressive solvents or corrosive substances without the risk of material degradation. Choosing the right grade of stainless steel, such as 304 or 316L, can enhance their adaptability to specific chemical environments.

6. Enhanced Performance Stainless steel mesh filter cartridges can be fitted onto existing filtration systems or designed into new systems to enhance overall filtration performance. They are effective in removing particulates, thus improving the quality of the final product, whether it’s food and beverage, industrial chemicals, or pharmaceuticals.

Applications in Industry

The versatility of stainless steel mesh filter cartridges lends to a broad range of applications. In the food and beverage industry, they are used to filter out particles during food processing, ensuring the final products are clean and safe for consumption. In the pharmaceutical industry, these cartridges help maintain the purity of liquids by preventing contamination during the manufacturing process.

In chemical processing, stainless steel filters play a crucial role in removing catalyst fines and other particulates, which is critical to ensuring product quality and equipment longevity. Additionally, in wastewater treatment, they aid in the removal of suspended solids, thereby improving the efficiency of the treatment processes.

Conclusion

Stainless steel mesh filter cartridges represent a significant advancement in filtration technology. Their durability, reusability, and versatility make them an essential choice for various industries facing the challenges of effective filtration. As the need for clean and safe products continues to grow, incorporating stainless steel mesh filter cartridges into filtration systems will undoubtedly lead to enhanced performance and reduced operational costs. By investing in these filtration solutions, industries can improve their processes, product quality, and environmental footprint, paving the way for a cleaner and more efficient future.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: