Tel:

+8618931101301

Tel:

+8618931101301

Nov . 12, 2024 04:26 Back to list

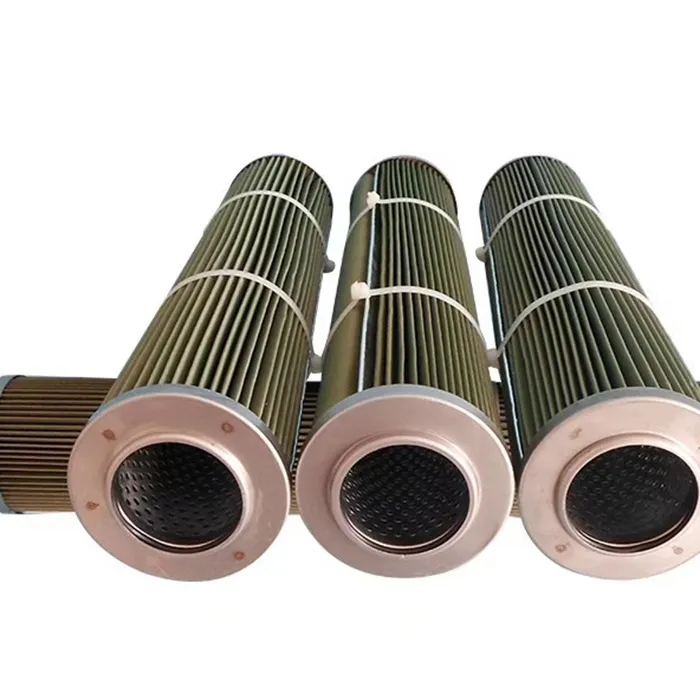

stainless steel filter element

The Significance of Stainless Steel Filter Elements in Modern Filtration Systems

In today's industrial landscape, ensuring the quality and purity of fluids is paramount. This is where filtration systems play a critical role, and one of the key components within these systems is the stainless steel filter element. Composed of durable stainless steel, these filter elements offer numerous advantages across various applications, including water treatment, food and beverage processing, chemical manufacturing, and oil and gas industries.

What are Stainless Steel Filter Elements?

Stainless steel filter elements are designed to remove particulates, impurities, and contaminants from fluids. They are constructed from stainless steel mesh or woven fabric, which can be engineered to various porosities depending on the application’s requirements. The main characteristics that define these filter elements are their mechanical strength, resistance to corrosion, and ability to withstand high temperatures and pressures.

Advantages of Stainless Steel Filter Elements

1. Durability and Longevity Unlike traditional filter materials such as paper or synthetic fibers, stainless steel filter elements exhibit exceptional durability. They can endure high flow rates and extreme operating conditions without degrading, resulting in longer service life and reduced replacement costs.

2. Corrosion Resistance Stainless steel is inherently resistant to a wide range of corrosive substances, making it ideal for use in harsh environments. This resistance helps maintain the integrity of the filter over time, ensuring consistent filtration performance.

3. High Filtration Efficiency Stainless steel filter elements can be designed to capture particles of various sizes effectively. With precise engineering, these filters can achieve high levels of filtration efficiency, which is crucial in applications where even minute contaminants can lead to significant problems.

4. Easy Cleaning and Reusability Many stainless steel filters can be cleaned and reused, promoting sustainability and cost-effectiveness. Techniques such as backwashing, ultrasonic cleaning, and chemical cleaning allow for the removal of accumulated contaminants, restoring the filter's efficiency without the need for replacements.

stainless steel filter element

5. Customizability Stainless steel filter elements can be tailored to meet specific filtration needs. Whether the application requires a certain pore size, shape, or structure, manufacturers can produce filter elements that suit individual requirements, enhancing operational effectiveness.

Applications of Stainless Steel Filter Elements

Stainless steel filter elements find applications across a diverse range of industries

- Water Treatment In municipal water treatment plants, stainless steel filters are crucial for removing sediment and other impurities, ensuring clean drinking water. They also play a significant role in wastewater treatment processes.

- Food and Beverage Industry In this sector, maintaining high hygiene standards is essential. Stainless steel filter elements are used in processes such as filtration of beer, wine, and juices where they help eliminate unwanted particulates while complying with safety and health regulations.

- Chemical Processing The chemical industry often deals with aggressive substances that can corrode traditional filter materials. Stainless steel elements provide a reliable solution for filtering chemicals, ensuring continuity in production while safeguarding the equipment.

- Oil and Gas In the oil and gas sector, filtration is vital in both upstream and downstream operations. Stainless steel filters are employed to purify oil and gas fluids, protecting sensitive equipment and enhancing the overall efficiency of the operations.

Conclusion

Stainless steel filter elements serve as a cornerstone in modern filtration systems, providing robust, efficient, and sustainable solutions for a wide array of industries. Their durability, corrosion resistance, and high filtration efficiency make them an ideal choice for ensuring the purity of fluids in challenging environments. As industries continue to evolve and the demand for high-quality filtration increases, stainless steel filter elements will undoubtedly remain an essential component, contributing to safer and more efficient processes across the globe.

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

Email:

Email: