Tel:

+8615930870079

Tel:

+8615930870079

Nov . 27, 2024 09:11 Back to list

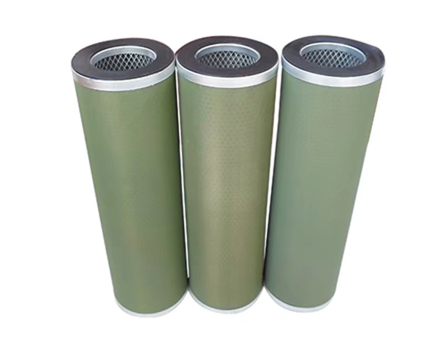

Sintered Metal Filter Cartridge Applications and Benefits for Industrial Filtration Solutions

The Advantages of Sintered Metal Filter Cartridges

In the modern industrial landscape, filtration systems play a crucial role in ensuring the purity and quality of liquids and gases. Among various filtration technologies, sintered metal filter cartridges have emerged as a preferred choice for many applications. These cartridges are distinguished by their robust design, longevity, and exceptional filtering capabilities. This article explores the advantages of sintered metal filter cartridges, providing insights into their applications, material properties, and overall effectiveness.

What Are Sintered Metal Filter Cartridges?

Sintered metal filter cartridges are made from metal powders that have been compacted and sintered in a high-temperature process. This process binds the particles together to form a porous structure. The result is a strong, durable filter capable of withstanding harsh conditions, extreme temperatures, and high pressures. The filtration mechanism involves a combination of depth filtration and surface filtration, allowing these cartridges to capture particles of various sizes efficiently.

Key Advantages

1. Durability and Longevity One of the primary benefits of sintered metal filters is their durability. Unlike traditional filter media made from paper or polymer, sintered metal cartridges can endure harsh chemical environments, high temperatures, and elevated pressures. This resilience translates into a longer service life, reducing the need for frequent replacements and ultimately lowering maintenance costs.

2. High Filtration Efficiency Sintered metal filters boast a unique porous structure that enables them to achieve high filtration efficiency. The interconnected pore sizes can be tailored during the manufacturing process, allowing users to select the appropriate filter for specific applications. This adaptability makes them suitable for various industries, including pharmaceuticals, food and beverage, and petrochemicals.

3. Easy Cleaning and Reusability Another significant advantage of sintered metal filters is their cleanability. Unlike disposable filter media, these cartridges can often be cleaned using backwashing or ultrasonic cleaning methods. This feature enhances their sustainability by allowing users to reuse the cartridges multiple times, thus reducing waste and operational costs.

sintered metal filter cartridge

4. Chemical Compatibility Sintered metal filter cartridges are available in a range of materials, including stainless steel, bronze, and special alloys. This versatility allows them to handle a wide variety of fluids and gases, including aggressive chemicals. Users can select the best material to suit their specific application, ensuring optimal performance and longevity.

5. Minimal Pressure Drop The design of sintered metal filters allows for efficient flow rates with minimal pressure drop, which is crucial in many applications. The low resistance to flow means that pumps do not need to work as hard, leading to energy savings and prolonged equipment life.

6. Precision Filtration Sintered metal filters can achieve precise filtration ratings, ranging from microns down to sub-micron levels. This precision is essential in applications where cleanliness is paramount, such as in semiconductor manufacturing or high-purity water filtration.

Applications of Sintered Metal Filter Cartridges

Sintered metal filter cartridges find applications across a broad spectrum of industries. In the oil and gas sector, they are used to filter out particulates and contaminants from crude oil and natural gas. The food and beverage industry relies on them for microfiltration of beverages and the removal of solids from oils. Additionally, they are critical in pharmaceutical manufacturing, protecting sensitive processes and products from contamination.

Conclusion

Sintered metal filter cartridges offer an excellent solution for filtration needs, combining durability, efficiency, and versatility. As industries strive for higher quality and purity standards, the advantages of these cartridges have made them increasingly popular. Whether in demanding environments or routine applications, sintered metal filters provide reliable performance, making them a smart choice for any filtration requirement. In the face of growing environmental concerns, their reusability and sustainability further emphasize the importance of adopting such innovative filtering technologies. Embracing sintered metal filter cartridges can significantly contribute to operational efficiency and product quality across various sectors.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: