Tel:

+8618931101301

Tel:

+8618931101301

Nov . 10, 2024 20:31 Back to list

High-Performance Sintered Metal Filter Cartridges for Efficient Filtration Solutions

Sintered Metal Filter Cartridges An In-Depth Overview

The growing demand for efficient filtration solutions across various industries has led to the evolution of several technologies aimed at improving performance and durability. One such innovation is the sintered metal filter cartridge. This article delves into the significance, applications, benefits, and future prospects of sintered metal filter cartridges in modern filtration systems.

What is a Sintered Metal Filter Cartridge?

A sintered metal filter cartridge is a type of filtration device made from powdered metal that has been sintered, or heated, to form a solid structure without melting it completely. This process bonds the metal particles together, creating a porous medium with uniform pore sizes. The result is a filter that offers enhanced mechanical strength, thermal stability, and resistance to harsh chemicals. Common materials used for sintered metal filters include stainless steel, bronze, and titanium, which offer varying characteristics suited for different applications.

Applications of Sintered Metal Filter Cartridges

Sintered metal filter cartridges are utilized in a myriad of sectors due to their versatility and robustness. Key applications include

1. Oil and Gas Industry In this sector, sintered metal filters are employed to purify crude oil and natural gas by removing particulates and impurities. Their ability to withstand high temperatures and pressures makes them ideal for use in harsh operational environments.

2. Chemical Processing The chemical industry often requires filters that can handle corrosive substances. Sintered metal filter cartridges can efficiently filter chemicals without degrading over time, providing a longer service life compared to polymer-based filters.

3. Food and Beverage In applications involving food and beverage production, purity is paramount. Sintered metal filters ensure the removal of unwanted particles while complying with stringent sanitary guidelines.

5. Pharmaceuticals The pharmaceutical industry utilizes sintered filters for sterile filtration processes, where maintaining the integrity of the product is critical. These filters can be precisely manufactured to meet specific filtration requirements.

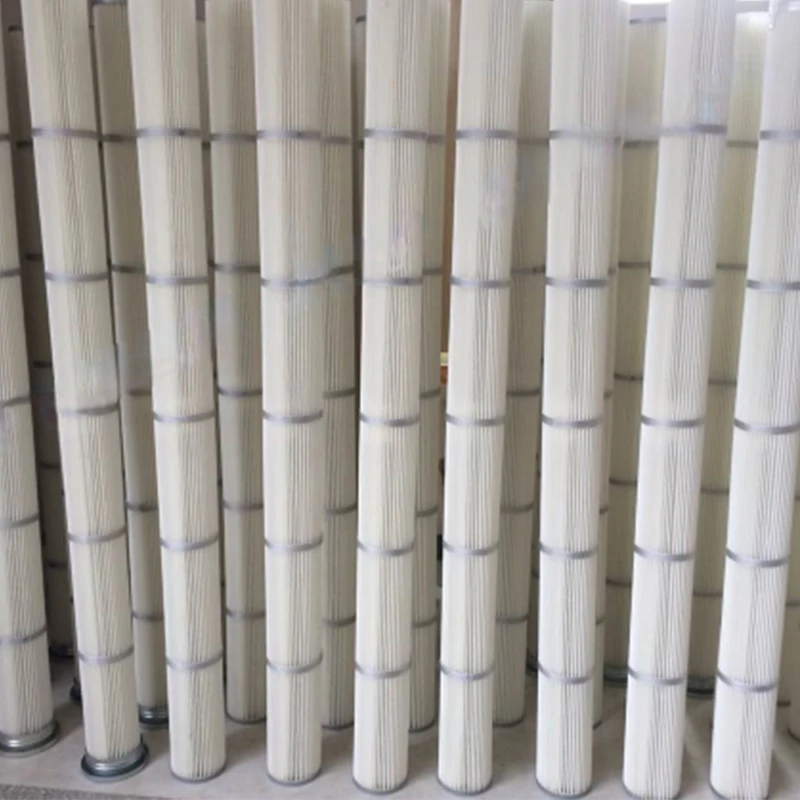

sintered metal filter cartridge

Advantages of Sintered Metal Filter Cartridges

1. Durability One of the most significant advantages of sintered metal filters is their durability. They can endure extreme conditions such as high temperatures, pressures, and aggressive chemicals, making them suitable for a wide range of applications.

2. Reusability Unlike many disposable filters, sintered metal cartridges can be cleaned and reused multiple times. This feature not only reduces operational costs but also minimizes waste, making them an environmentally friendly option.

3. High Filtration Efficiency With the capability to achieve precise pore sizes, sintered metal filters effectively trap particles of varying sizes, ensuring high filtration efficiency and improved product purity.

4. Customization Sintered metal filters can be manufactured to meet specific porosity and size requirements, allowing businesses to tailor their filtration solutions according to unique operational needs.

5. Resistance to High Temperatures The materials used in sintered metal filters are capable of withstanding high temperatures without significant degradation, making them indispensable in applications that involve heat.

Future Prospects

As industries continue to evolve and demand more sophisticated filtration systems, the future of sintered metal filter cartridges appears promising. Ongoing advancements in materials science and manufacturing techniques may lead to even more efficient designs, further enhancing performance while reducing costs.

Moreover, as sustainability becomes a central focus in industrial processes, the reusability and longevity of sintered metal filters will likely position them as leaders in sustainable filtration solutions. The ongoing integration of smart technology, such as IoT, could also enhance monitoring and maintenance practices, ensuring optimal performance and efficiency.

Conclusion

Sintered metal filter cartridges represent a significant advancement in filtration technology, combining durability, efficiency, and environmental responsibility. As various industries continue to seek reliable filtration solutions, these cartridges will undoubtedly play a crucial role in meeting their needs while adhering to safety and sustainability standards. Their adaptability across different applications ensures that they will remain a pivotal component of industrial processes well into the future.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: