Tel:

+8615930870079

Tel:

+8615930870079

Jul . 25, 2024 15:20 Back to list

Effective Strategies for Selecting and Maintaining Air Intake Filters for Turbines

Understanding Turbine Air Intake Filters Importance and Functionality

Turbine air intake filters play a critical role in the performance and longevity of turbomachinery, which includes gas turbines, jet engines, and various types of industrial machinery. These filters are designed to protect the engine's internal components from harmful contaminants present in the atmosphere, such as dust, dirt, and other particulates. In this article, we will explore the importance of turbine air intake filters, their functionalities, and the maintenance practices necessary to ensure their optimal performance.

The Importance of Air Intake Filters

Turbomachinery operates under extreme conditions, where the efficiency of air intake systems directly affects performance. Air intake filters serve as the first line of defense against airborne particles that can damage engine components, leading to reduced efficiency, increased wear, and potential failure. Contaminated air can cause problems such as compressor fouling, increased operating temperatures, and reduced power output. By filtering out harmful particles, turbine air intake filters enhance the operational reliability and longevity of the machinery.

Moreover, the presence of clean air is essential for the combustion process in gas turbines. A steady and unpolluted air supply ensures optimal combustion, leading to higher efficiencies and reduced emissions. This is particularly relevant in today’s environmental landscape, where regulations regarding pollutants are becoming increasingly stringent. Efficient air intake filters contribute not only to engine performance but also to compliance with environmental standards.

Functionality of Turbine Air Intake Filters

Turbine air intake filters are designed using advanced materials and technologies to ensure high efficiency in particle removal. These filters typically employ multi-stage filtration systems, incorporating various mechanisms such as inertial separation, impaction, and diffusion to capture a broad spectrum of particle sizes. The selection of filter material is crucial; it must balance airflow resistance with particle retention capabilities.

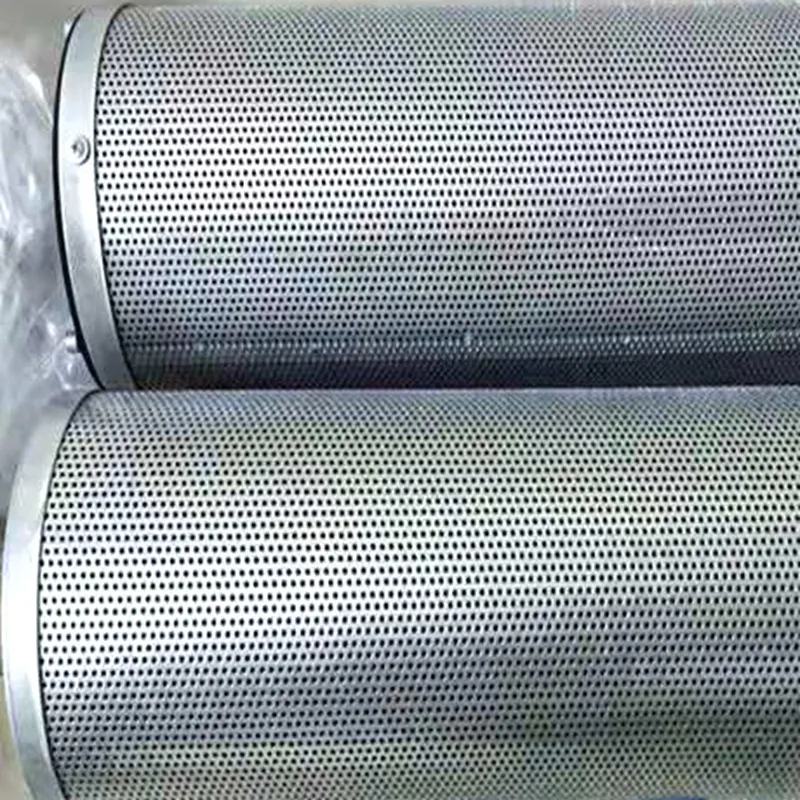

turbine air intake filters

There are generally two types of air intake filters dry filters and wet filters. Dry filters are commonly used for most applications due to their lightweight design and ease of maintenance. They capture particles through electrostatic attraction and mechanical sieving. Wet filters, on the other hand, are used in specific environments where high moisture levels are present. They require a different maintenance regimen but can be effective in capturing smaller particles that dry filters may miss.

Maintenance of Air Intake Filters

To ensure the ongoing effectiveness of turbine air intake filters, regular maintenance is essential. This maintenance typically includes scheduled inspections, cleaning, and, when necessary, replacement. Inspections can help identify any clogging or damage early, preventing more significant issues down the line. Cleaning can often extend the life of a filter, especially in less contaminated environments. However, it is critical to follow the manufacturer’s guidelines regarding cleaning methods and frequency, as improper cleaning can lead to reduced filter efficiency.

Replacing air intake filters at intervals specified by the manufacturer ensures that engines remain protected against contaminants. Failure to replace filters can lead to excessive buildup of particulates, resulting in increased pressure drop, reduced airflow, and ultimately engine inefficiency.

Conclusion

In conclusion, turbine air intake filters are indispensable to the functioning of turbomachinery, significantly affecting performance, reliability, and compliance with environmental standards. Understanding their importance, functionality, and maintenance requirements is essential for anyone involved in the operation or upkeep of turbo machinery. By prioritizing proper filtration, operators can ensure their systems run efficiently and effectively, safeguarding their investments while adhering to environmental commitments.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: