Tel:

+8615930870079

Tel:

+8615930870079

Dic . 17, 2024 04:31 Back to list

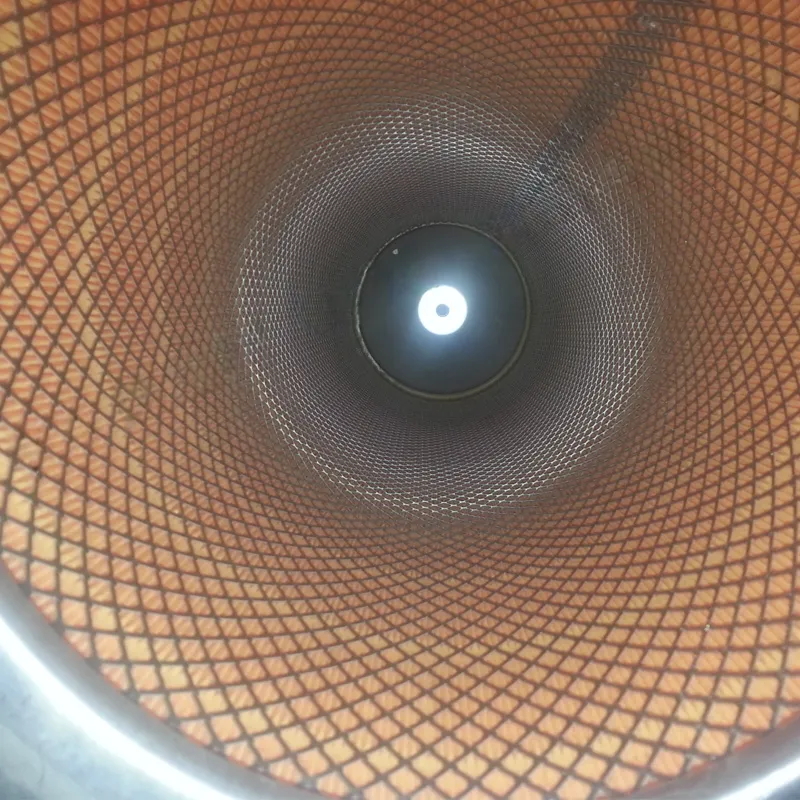

antistatic filter element

Understanding Antistatic Filter Elements Importance and Applications

In various industrial applications, the management of static electricity is crucial for maintaining product quality and ensuring safety. One of the innovative solutions to combat static electricity in fluid filtration systems is the use of antistatic filter elements. These specialized filters not only purify fluids but also mitigate the risks associated with static charges that can lead to fires or explosions in hazardous environments.

What Are Antistatic Filter Elements?

Antistatic filter elements are specifically designed filtration devices that possess properties to prevent the buildup of static electricity during the filtration process. Traditional filter elements are made from non-conductive materials, which can inadvertently accumulate static charges. These charges can become problematic when dealing with flammable liquids or powders, where even a small spark can result in catastrophic outcomes. In contrast, antistatic filter elements incorporate conductive materials or coatings that dissipate static charges safely and effectively, thus reducing the risk of ignition.

Key Features and Benefits

1. Static Charge Dissipation The primary advantage of antistatic filter elements is their ability to dissipate static electricity. By providing a path for charges to flow away, these filters minimize the risk of static discharge events.

2. Enhanced Safety In industries such as petrochemicals, pharmaceuticals, and food production, managing static electricity is essential. Antistatic filters add an extra layer of safety, helping to comply with strict regulations regarding electrostatic discharge and fire hazards.

3. Improved Efficiency Static electricity can attract dust and particles, leading to frequent clogging of traditional filters. Antistatic filter elements help maintain cleaner fluid pathways, enhancing overall filtration efficiency and extending the lifespan of the filter.

4. Versatility These elements can be used in various systems, including liquid and gas filtration setups. Their versatility makes them suitable for diverse applications, ranging from paint and coatings to food and beverage processing, and even in cleanroom environments where contamination control is vital.

antistatic filter element

5. Customizability Antistatic filter elements can be tailored to fit specific needs. Manufacturers often provide options for different porosities, materials, and sizes, allowing users to select filters that best suit their operating conditions and requirements.

Applications of Antistatic Filter Elements

1. Pharmaceutical Industry In the production of pharmaceuticals, contamination must be minimized, and static electricity can lead to agglomeration or improper mixing of powders. Antistatic filters play a critical role in maintaining product integrity and ensuring safety.

2. Petrochemical Industry The processing of flammable liquids in the petrochemical industry poses significant explosion risks. Antistatic filter elements are essential for preventing static discharge during the handling and transfer of these substances, enhancing workplace safety.

3. Food Processing In food production and packaging, maintaining sanitation and preventing contamination are top priorities. Antistatic filters can help achieve these goals while also preventing the static electric buildup that can attract unwanted particles and contaminants.

4. Electronics Manufacturing The electronics sector often requires exceptionally clean environments. Antistatic filters help in removing particles from air or gases used in manufacturing processes, safeguarding sensitive electronic components from damage caused by static discharges.

5. Chemical Processing The chemical industry frequently deals with volatile substances. By employing antistatic filter elements, companies can significantly reduce the risk associated with static electricity during various chemical processes, protecting both employees and products.

Conclusion

Antistatic filter elements are an invaluable innovation in the realm of fluid filtration. Their ability to mitigate static electricity not only enhances safety and efficiency but also serves as a critical component in various high-risk industries. As industries continue to evolve and face new challenges, the role of advanced filtration solutions like antistatic filter elements will undoubtedly expand, ensuring safer and more efficient operations in the long run. Embracing these technologies is a step toward achieving comprehensive safety and quality management in industrial processes.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: